"Quality is measured over time" - The case study for our rotary joint reconditioning service

As good as new. Our rotary joint reconditioning service gives the product perfect functionality "as if it had just left the factory". We are so confident in the result that we guarantee it.

All mechanical components have a 'life cycle' and when they are used in particularly heavy-duty applications, for parts exposed to normal wear and tear, it is necessary to carry out some checks and professional maintenance so that the system always works at its best.

Let's take one of our customers as an example who treats animal waste (or also called 'rendering') with its plants. Treating slaughterhouse waste such as bones, blood, feathers, carcasses, leather, and turning them into bone and meat flour, makes it possible to deal with a large market and many fields of application. But the operating conditions of these plants are very demanding as they take over the whole 'dirty' part of the slaughterhouse production.

Due to the application, you would expect a normal rotary joint to start showing the first signs of wear after about 2-3 years, but KADANT and Johnson-Fluiten products are a special case. The design, the quality in the choice of materials and the care taken in the manufacture of our rotary joints allow us to rely on consistent performance, in some cases for more than three times as long.

Indeed, after more than 5 years of intensive use, one of our customers contacted Johnson-Fluiten's service department, who had received a 5" double-pass KADANT rotary joint, to request a total reconditioning due to the presence of small steam leaks. The restoration of the component's efficiency should have been total, the aim of the service was to restore the joint to the same condition in which it had left the factory many years before.

After carefully disassembling the joint, Johnson-Fluiten technicians checked the wear condition of the seal, which had lost its integrity and expired its natural life due to use. Several checks and dimensional inspections of all parts of the joint were carried out to verify the actual condition of the component. Once this phase was completed, it was possible to replace the graphite, the internal seals and carry out a deep cleaning of the parts that did not need to be changed.

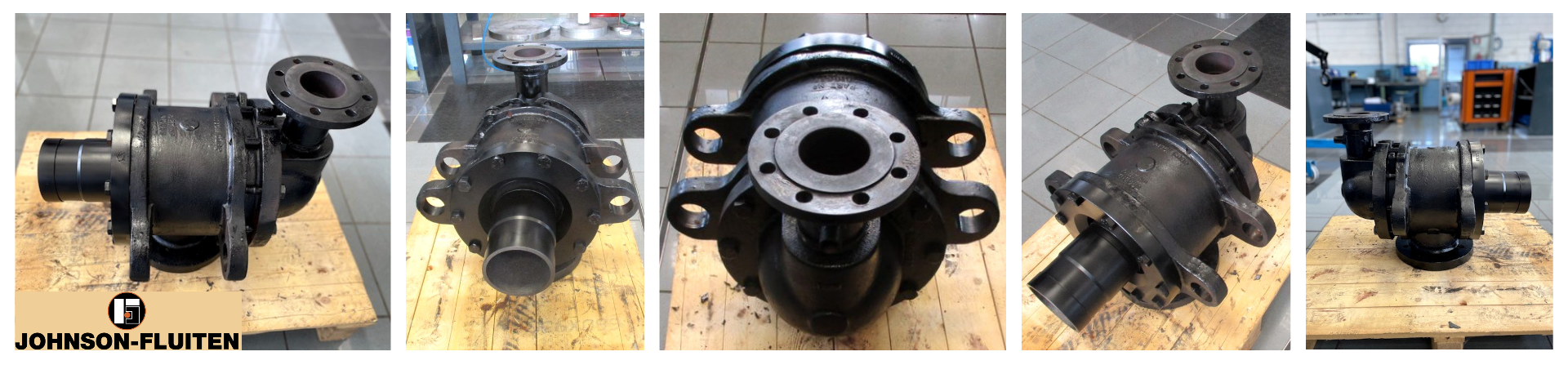

After this professional and accurate procedure, the joint was mounted on the customer's machine to verify that the original performance had been restored. Here we can see the result:

BEFORE:

AFTER:

The rotary joint regeneration service carried out by Johnson-Fluiten technicians has made it possible to restore the KADANT joint to 100%, and so to really have an 'as new' product. This maintenance service carried out by skilled professionals is guaranteed by Johnson-Fluiten, for which the component is truly 'as new' in every sense, and comes with an official warranty.

The quality of our products is also measured in time. By using Johnson-Fluiten's remanufacture, repair and reconditioning service for rotary joints, you can have a component that is always at top efficiency with impressive cost savings compared to buying a new component.

Contact our SERVICE technicians for more information.

If you would like to carry out the maintenance yourself, we recommend that you contact our staff to request a replacement kit with original KADANT - Johnson-Fluiten parts. The use of original spare parts is the only way to ensure that the quality and performance of the product meets the original design requirements.