-

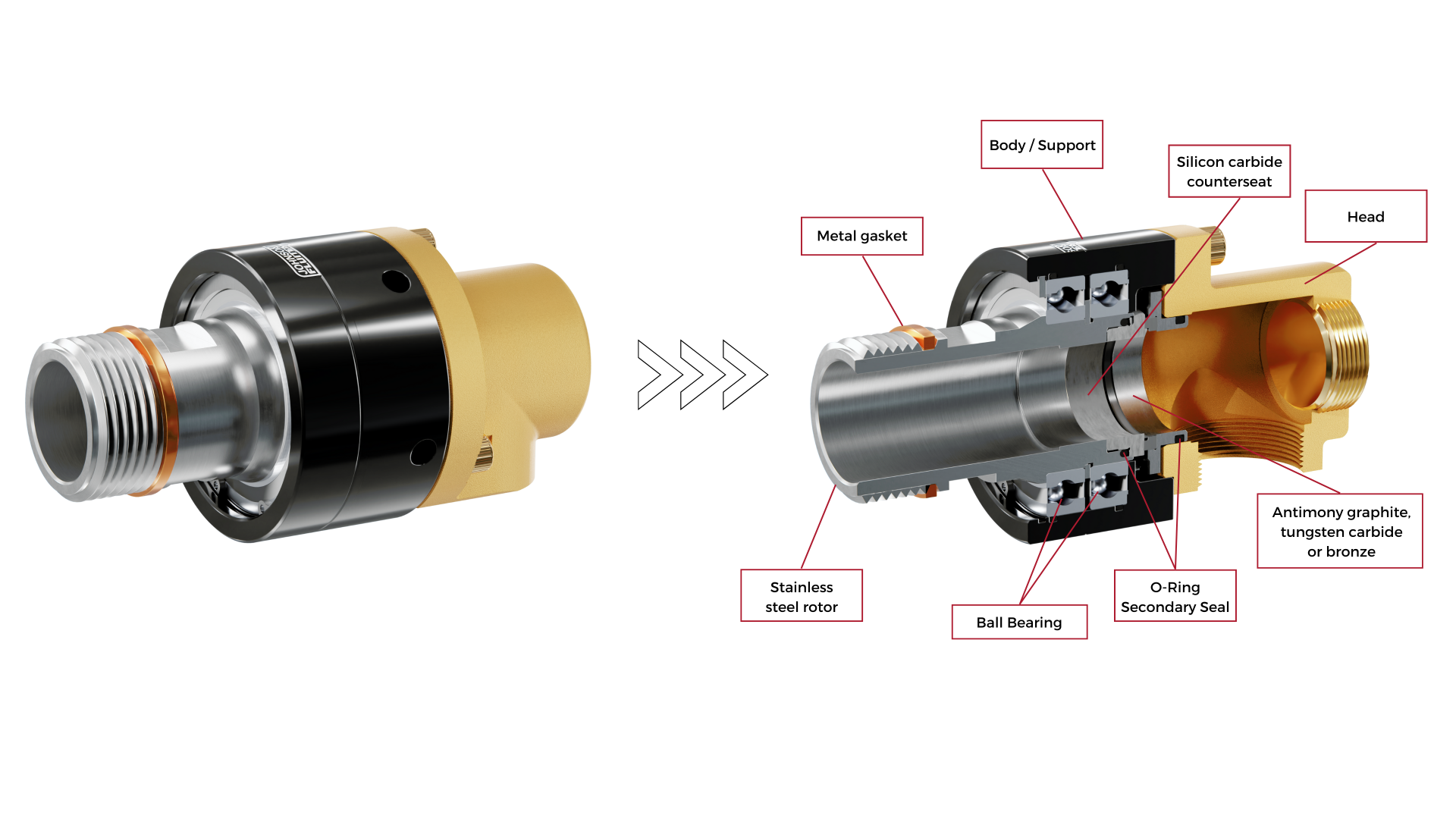

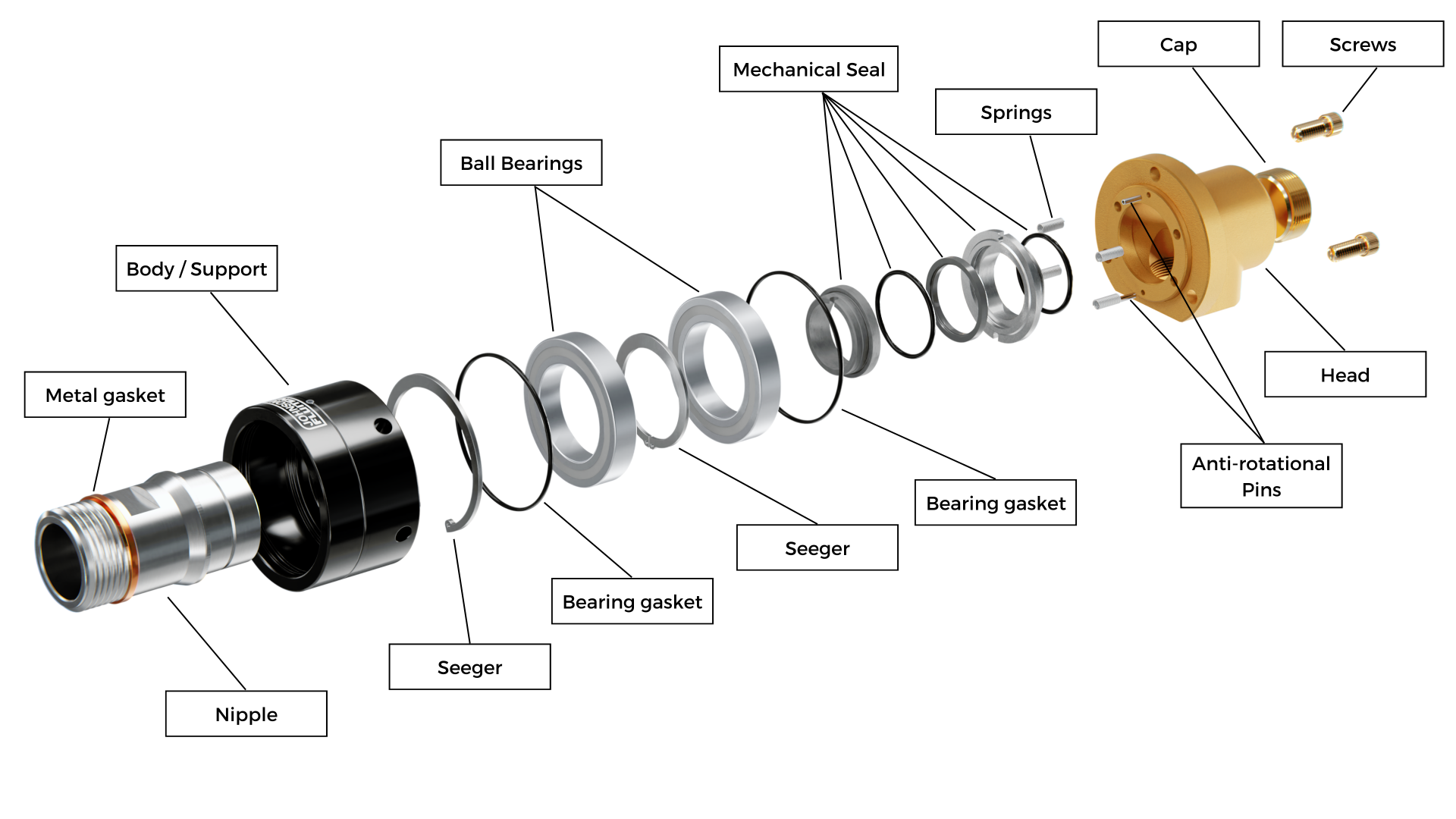

1 - BODY

The body is equipped with one or more inlet passages, generally threaded, which flexible inlet / outlet hoses will be connected to.

In the case of several passages, the inlet serves to introduce the fluid, while the outlet through the internal siphon tube to extract the fluid from the cylinder or roller which the joint is installed on.