How Johnson-Fluiten Rotary Unions Enhance Kaplan Turbine Performance

Kaplan hydroelectric turbines have long been a staple in green energy generation. However, their efficiency and productivity have reached new heights thanks to the precision and reliability of Johnson-Fluiten rotary unions. Let's dive into how this innovation is powering a more sustainable world.

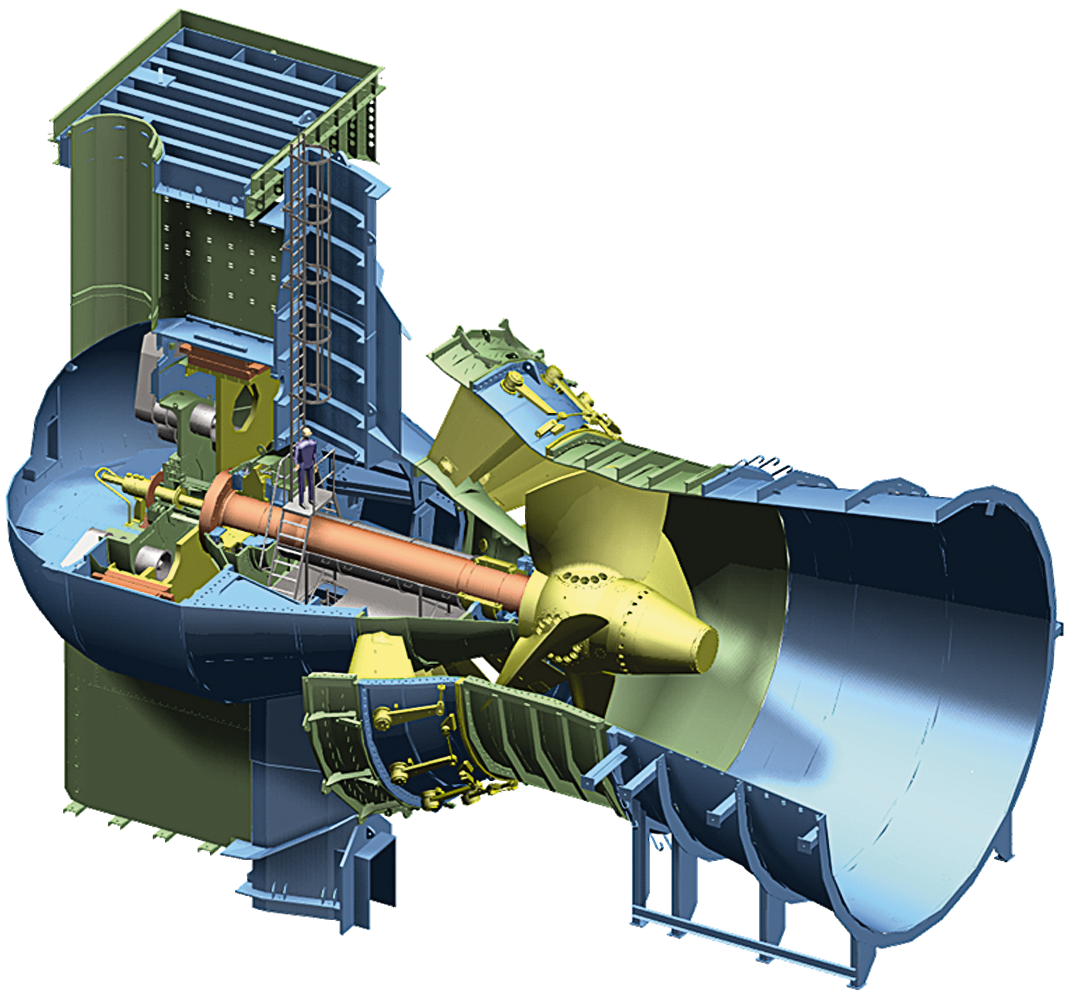

The Legacy of Kaplan Turbines

Invented in 1912, Kaplan turbines have been a proven solution for generating green energy with an efficiency of over 90%. These turbines operate within a typical rpm range of 50-500, and controlling this speed is crucial for optimal performance. The key to this control lies in the turbine's wicket gate and blade pitch mechanisms.

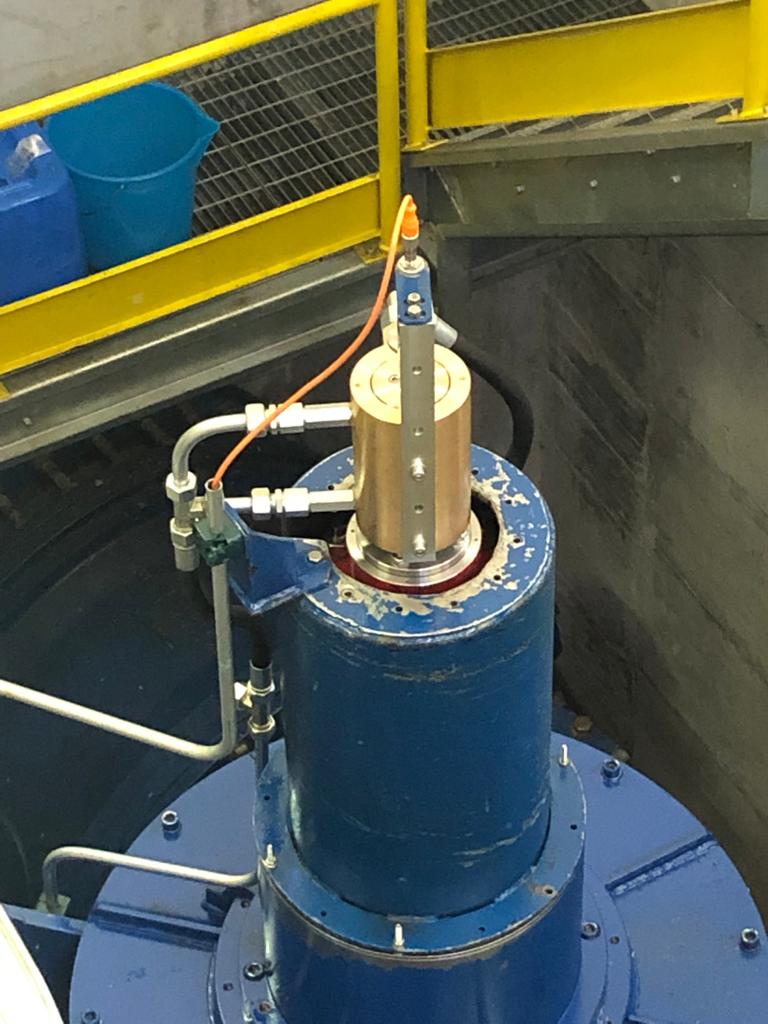

The Role of Johnson-Fluiten Rotary Unions

Johnson-Fluiten rotary unions play a vital role in enhancing the performance of Kaplan turbines. These unions transfer hydraulic pressure from the pump to the rotating blades, a process critical for maintaining the turbine's efficiency. The hydraulic pressure can reach as high as 100 bar (1500 psi), posing significant challenges for traditional sealing technologies.

Overcoming Sealing Challenges

Conventional polymer seals, like lip seals, struggle to withstand the high pressure and rpm combination, leading to rapid wear. Mechanical seals, while potentially more durable, risk catastrophic failure that could result in significant oil leaks and loss of turbine control. Johnson-Fluiten addresses these issues with their innovative close gap seal technology.

The Johnson-Fluiten Advantage

Johnson-Fluiten rotary unions are designed with micron precision to create a small gap seal. This non-contacting seal minimizes wear, ensuring high reliability and control. Any leaked oil is captured and recirculated within the system, preventing waste and maintaining environmental and efficiency standards.

Custom Solutions and Enhanced Productivity

Beyond their advanced sealing technology, Johnson-Fluiten offers customizable solutions tailored to specific needs. They can engineer unions to include mounting positions for sensors or accommodate various hose connections. This flexibility ensures compatibility with older turbine models, easing procurement challenges and boosting productivity.

A Global Partnership

Johnson-Fluiten represents a collaboration between Kadant Johnson and Fluiten Italia Spa. Kadant Johnson provides extensive sales and service support worldwide, while Fluiten’s expertise in mechanical seals drives innovation. Together, they offer comprehensive solutions to enhance energy production efficiency and sustainability.

Join the Green Energy Revolution

Johnson-Fluiten’s products and solutions are designed to improve your productivity and energy efficiency. To learn more about how their rotary unions can transform your Kaplan turbines, contact us today.

We’re eager to share our insights and provide solutions that meet your unique needs. Discover the benefits of partnering with Johnson-Fluiten and take a step towards a more sustainable future.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091