Clean energy from water: what lies behind the efficiency of hydroelectric turbines?

The race towards a sustainable future is not only fought in large-scale renewable energy projects, but also in the technical details that often go unnoticed by non-specialists. Here is where rotary unions, used in Kaplan turbines for hydroelectric power generation, become the key to transforming water movement into clean electricity.

Hydroelectric comparison: differences between turbines

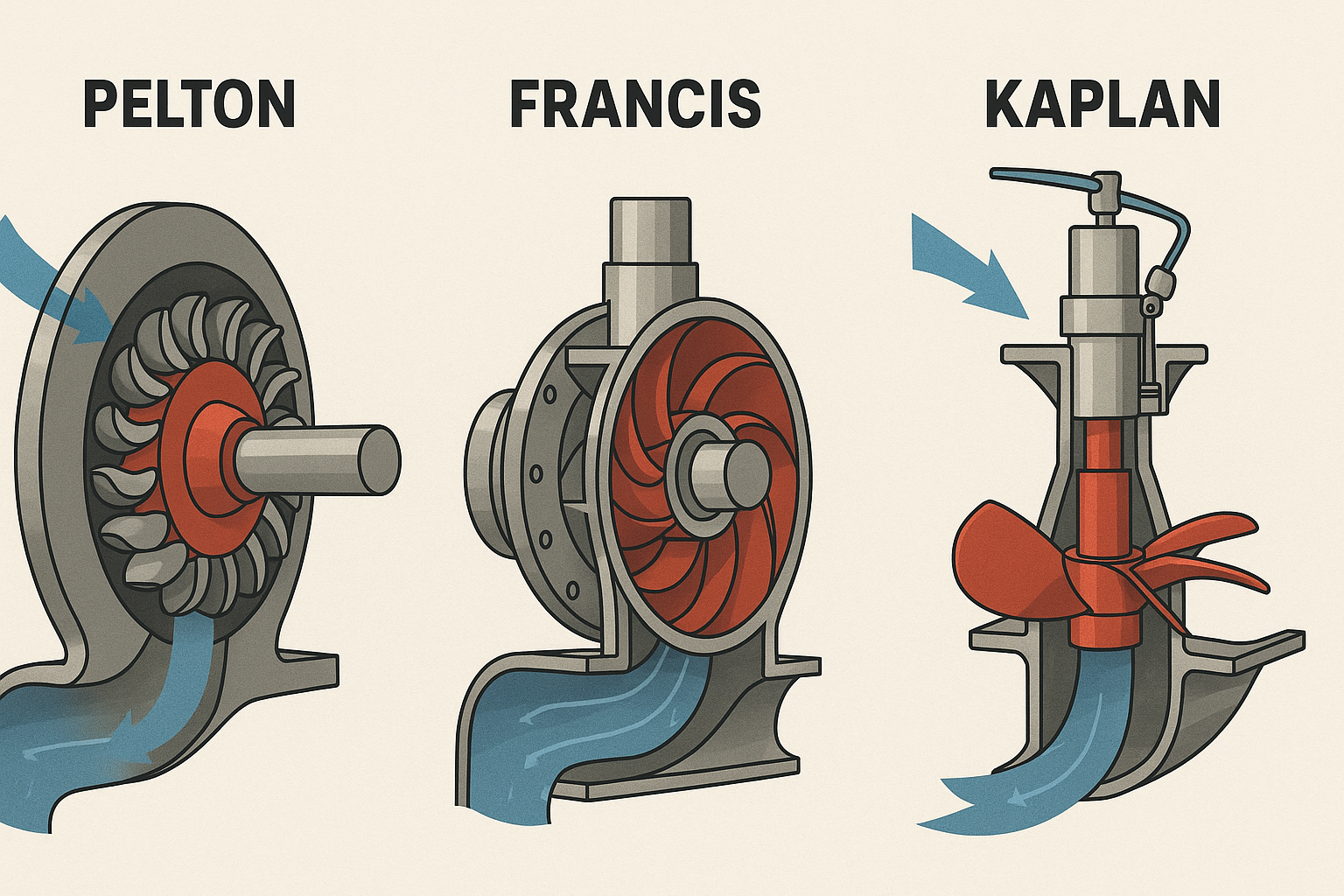

In the hydroelectric sector, several types of turbines are used to generate clean energy, among which the most common are Pelton, Francis and Kaplan turbines. The choice mainly depends on the hydraulic head and the water flow available.

-

Pelton turbines are designed for very high heads and low flows. They are ideally used in mountain plants, where steep gradients make it possible to concentrate large amounts of energy into high-speed water jets.

-

Francis turbines are best suited for medium heads and medium-to-high flows. Today, they are the most widely used type worldwide thanks to their versatility and reliability across different contexts.

-

Kaplan turbines, finally, were developed to handle challenging conditions: low heads and very high flows, typical of large rivers or artificial canals. In these cases, to maintain high efficiency it is not enough to regulate the flow with fixed gates: it is also necessary to adjust the incidence angle of the adjustable blades, continuously optimising turbine efficiency.

Kaplan turbines: over a century in the service of renewable energy

In 1912, Austrian engineer Viktor Kaplan patented an idea destined to change the history of hydroelectric production: a propeller turbine with adjustable blades, capable of adapting to variations in flow and head.

Since then, Kaplan turbines have established themselves as the ideal solution for low-head but high-volume waterways, managing to convert more than 90% of the available kinetic energy into electricity.

Their strength lies in the ability to regulate the blade angle, which makes it possible to maintain optimum efficiency regardless of flow variations. And this is precisely where the rotary union technology developed by Johnson-Fluiten comes into play.

Where is a rotary union needed in Kaplan turbines?

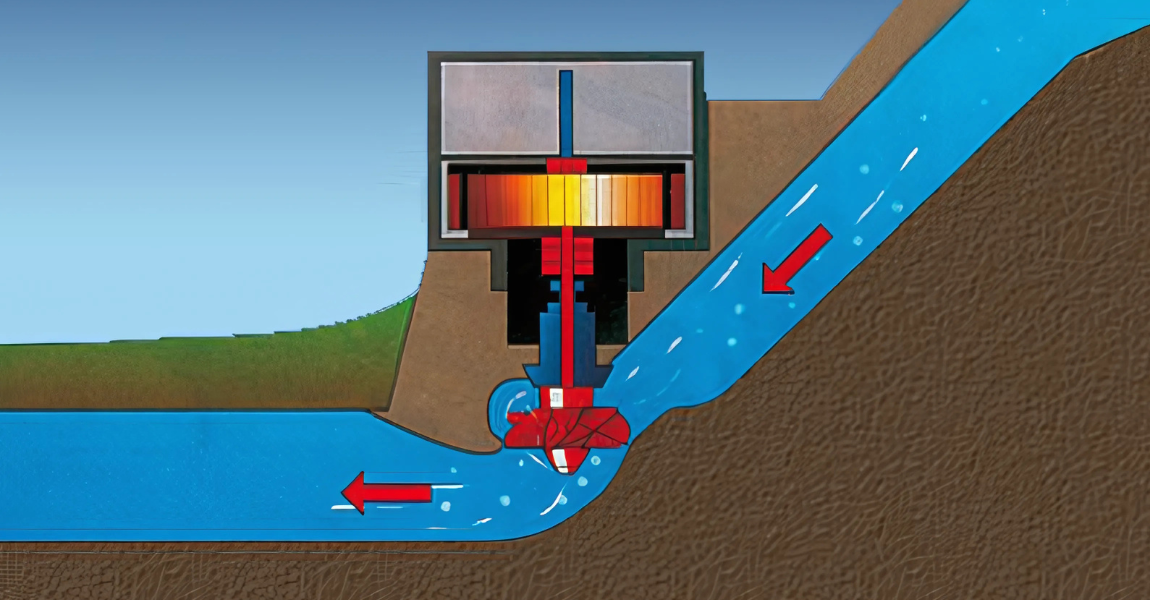

For a Kaplan turbine to operate at its full potential, the blades must be able to change pitch. This adjustment is managed by hydraulic cylinders, which in turn require a continuous and secure connection between the stationary and rotating parts of the turbine.

The task of the rotary union is exactly this: to transfer pressurised hydraulic oil into the system. A simple job in words, but extremely complex from an engineering perspective.

The technical challenge: high pressures, high flow rates, zero compromises

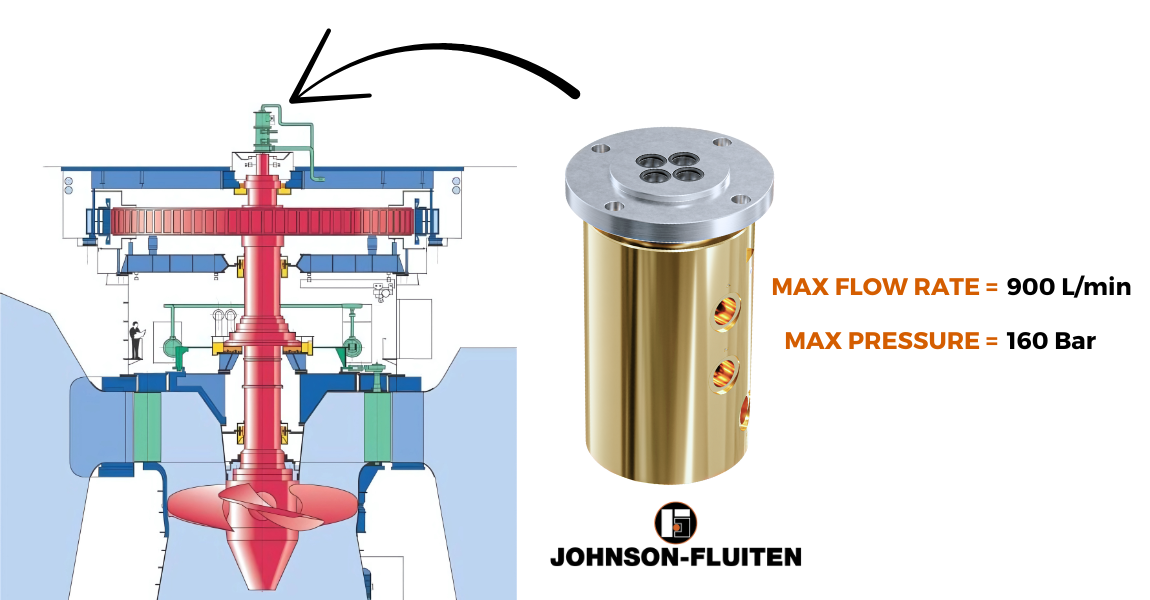

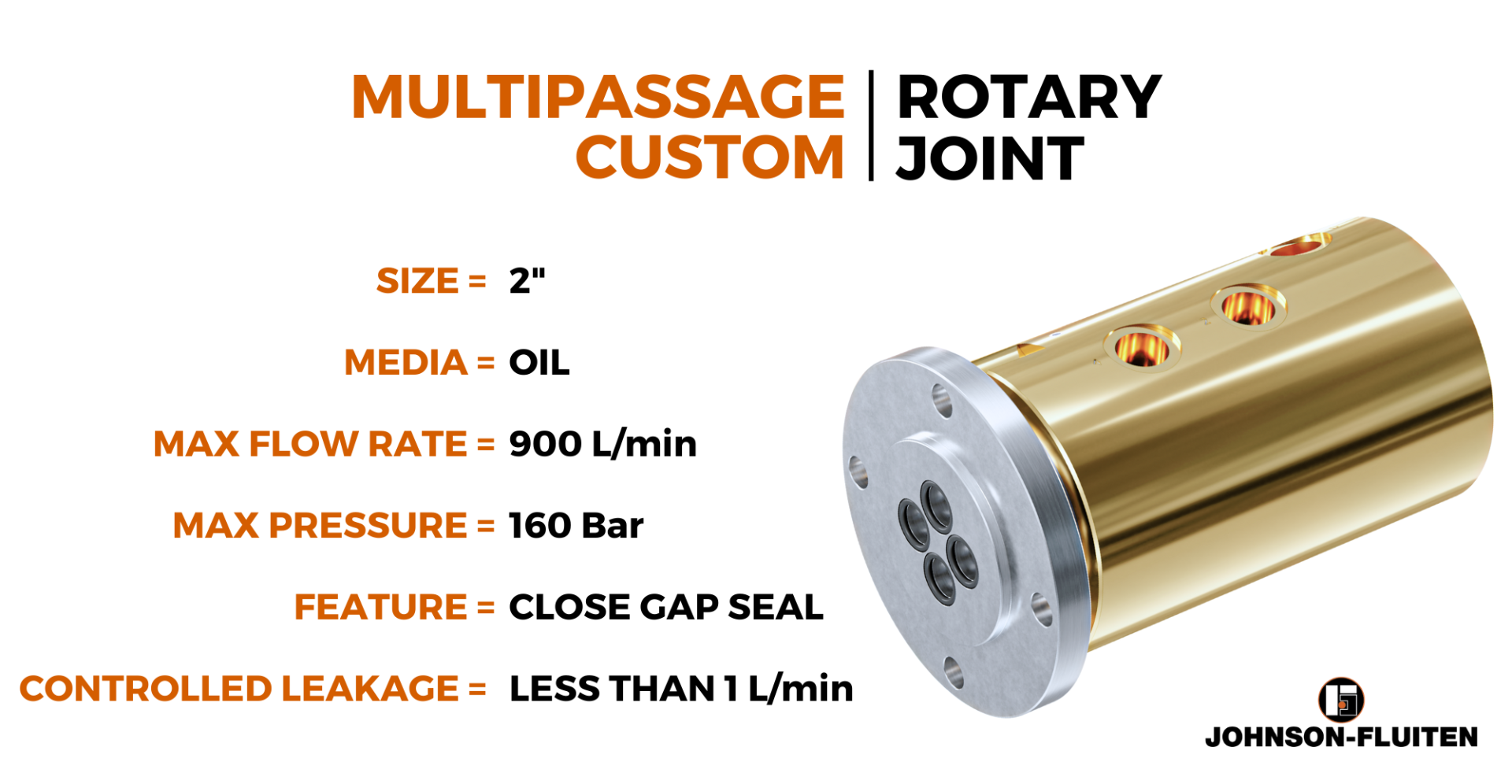

The latest rotary union developed for this application required the design of a custom multi-pass unit in order to:

-

Handle two hydraulic oil passages at pressures up to 160 bar.

-

Withstand an extraordinary required flow rate of 900 litres per minute (almost five times higher than a standard 2-passage rotary union).

These figures illustrate a challenge not only in design, but also in terms of materials, testing and reliability.

This resulted in the manufacture of a rotary union of impressive size: 2” (inches) in diameter, nearly 50 cm in height, and weighing over 200 kg.

Controlled leakage: when imperfection becomes an advantage

At such high pressures and flow rates, no conventional sealing technology can ensure completely leak-tight operation. Polymer seals such as lip seals would not withstand wear, while mechanical seals, although capable of handling pressure and rpm, could risk catastrophic failure with uncontrolled oil leakage.

The solution? A radically different approach: the close gap seal developed by Johnson-Fluiten.

This is a “controlled leakage” system: thanks to a micro-gap manufactured with micrometric precision, the union allows a minimal, continuous and predictable seepage. In laboratory tests, at 160 bar the leakage was found to be less than 1 litre per minute. This small flow is not an issue, since the oil is collected and recirculated into the system. The advantage is huge: no contact, reduced wear, and long-term reliability.

Customization: added value for hydropower

Every hydroelectric plant is different, and each Kaplan turbine has specific requirements. Johnson-Fluiten offers the possibility to design fully customised rotary unions, both for new installations and for retrofitting existing turbines.

An important aspect concerns compatibility with older turbines: in several cases, customers using unions from other manufacturers turned to Johnson-Fluiten due to the difficulty of sourcing original spare parts. Thanks to the ability to produce interchangeable units, the company helps extend the service life of legacy plants while maintaining high standards of efficiency and safety.

Clean energy, advanced engineering

Hydroelectric power will continue to be a cornerstone of the global energy mix, and Kaplan turbines will remain among the most efficient solutions for harnessing waterways. Investing in components such as Johnson-Fluiten rotary unions means investing in long-term reliability, safety and sustainability.

Behind sustainability lies a universe of precision engineering, and Johnson-Fluiten proves capable of integrating dependable, durable and high-performance technologies.

For engineers, production managers and maintenance professionals, the challenge is not only to keep turbines running, but to optimise them to the maximum. And this is precisely where Johnson-Fluiten can become the strategic partner able to turn a technical detail into a competitive advantage.

Author of the article

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091