How to win the challenge of customized production in the field of industrial components

In the current business context, there are many manufacturers of fluid management components that target the machine builder market. But not many of them can claim to have a track record of success in designing customized solutions for specific applications that are truly capable of providing real and measurable benefits

How we achieve, with our rotary joints, a leading place among the most important manufacturers of production lines in the plastics and rubber industry?

Let's find out the answer by analyzing the case of the development of the RX rotary joint with a "special head" for a major international customer that manufactures industrial plastic machinery; this project helped to simplify the customer's handling of components and ensured REAL & VERIFIED savings in time, energy and money.

The market background

The rotary joints previously used by our client, a large global player in the construction of rubber and plastics machinery, required the development and production of special heads to fit the special design of the machines.

This process was taking place in-house; the components were then used to adapt and mount rotary joints in the internal housings of their machines in the following applications: Preheater, Detaching Cylinders, Lifting Assembly, Embosser, and Cooler.

The study of the application and the standard component

The study of the application and the standard component

The challenge to face

The task for Johnson-Fluiten & Kadant johnson Europe staff was to come up with a solution that was going to bring real benefits to the customer. The goal was not to sell a product with improved performance, but to make the entire process simpler and more efficient to provide a real advantage over the previously adopted solution.

Application needs were then identified:

-

1 - Implementation of a rotary joint with a special head

-

2 - Change in the standard length of the joint rotor

-

3 - Adaptability to different media used such as: cold water, superheated water, diathermic oil

The development of the custom solution design

The development of the custom solution design

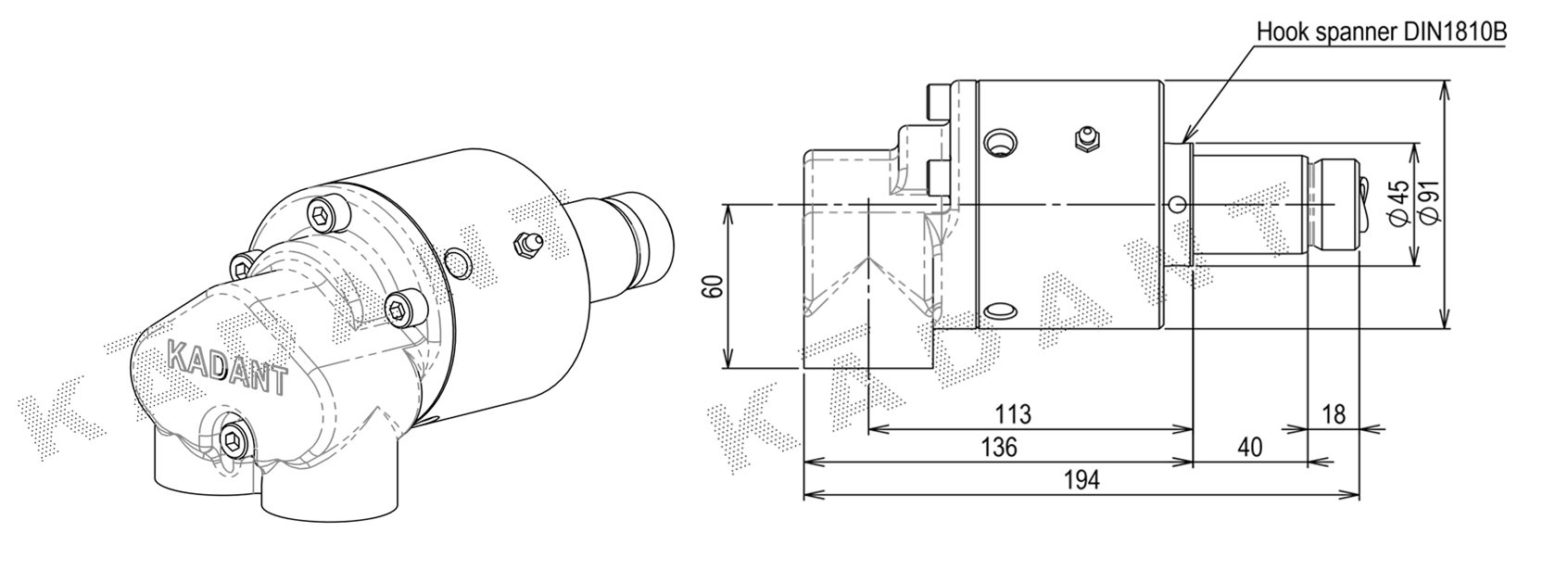

The evolution of the custom project

The technical team identified the solution by adapting the 1-inch RX rotary joint by increasing the length of the rotor by 20 mm and designing a complete custom flange that would fit the dimensions and specs of the machine to allow quick assembly and easier maintenance without the need to make additional design changes to the line.

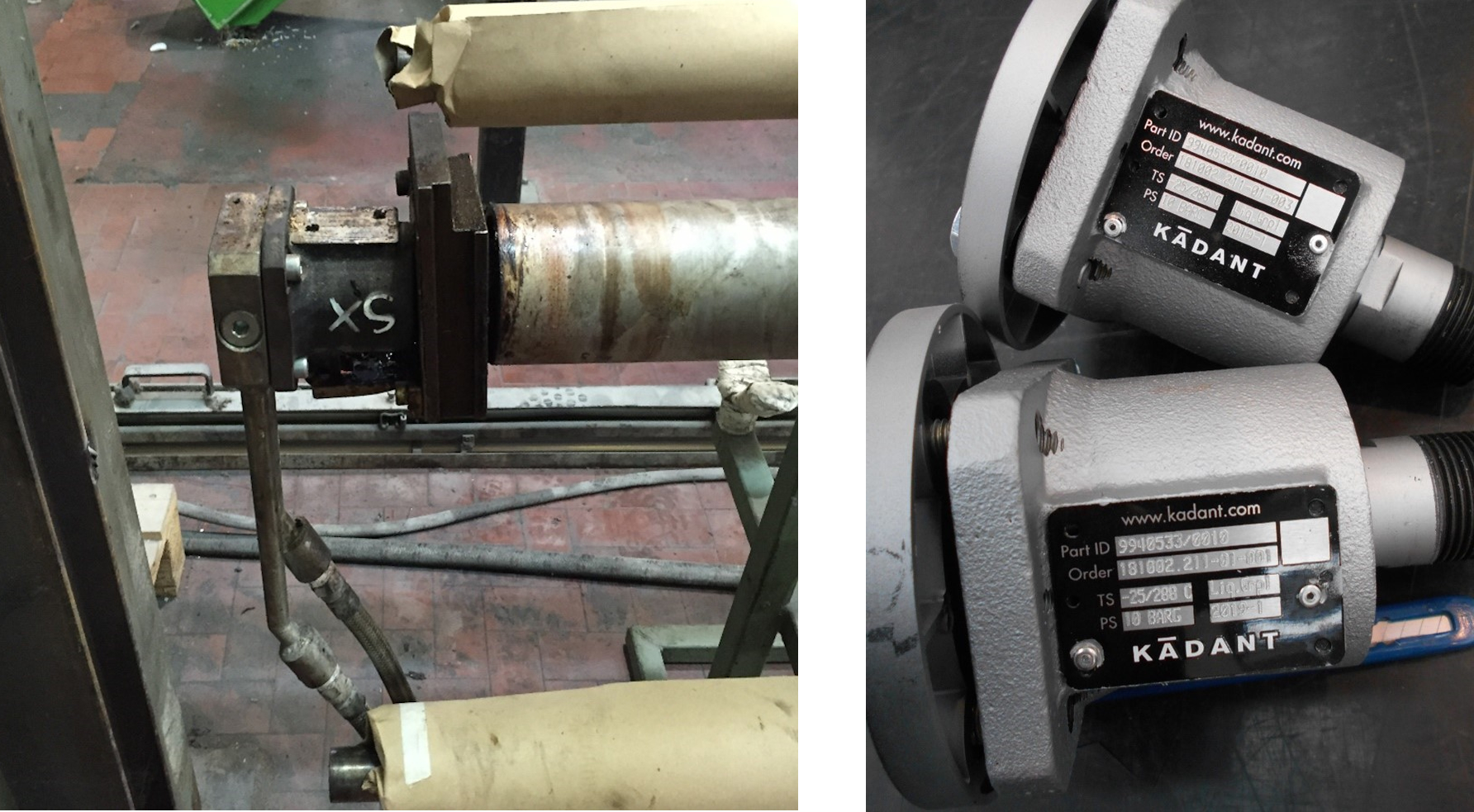

After the required surveys and preliminary tests, it was possible to produce a prototype within a tight timeframe to verify that the size, dimensions, and connections were 100% compatible with the technical solutions adopted on the machine produced by the customer.

After passing all preliminary tests, we mass-produced the component that became the standard in that line of machinery produced by the customer company.

The first prototype made

The first prototype made

The real and measurable benefits

The benefits reported by the customer were many and of high relevance considering that the rotary joint was delivered ready to be assembled:

-

Standardization

A single rotary joint for all the different media used (Diathermic Oil, Superheated Water, Cooling Water) thanks to the internal mechanical seal that can be easily changed

-

Simplification

The production management of the machine on which the new rotary joints are mounted has benefited; the number of codes handled in the warehouse has been reduced, and the assembly and maintenance timeframes have been greatly reduced

-

Decreased costs

The customer no longer has to be set up to make part of the component in-house; this has led to the resulting zero cost of in-house production and management

-

Quality increase

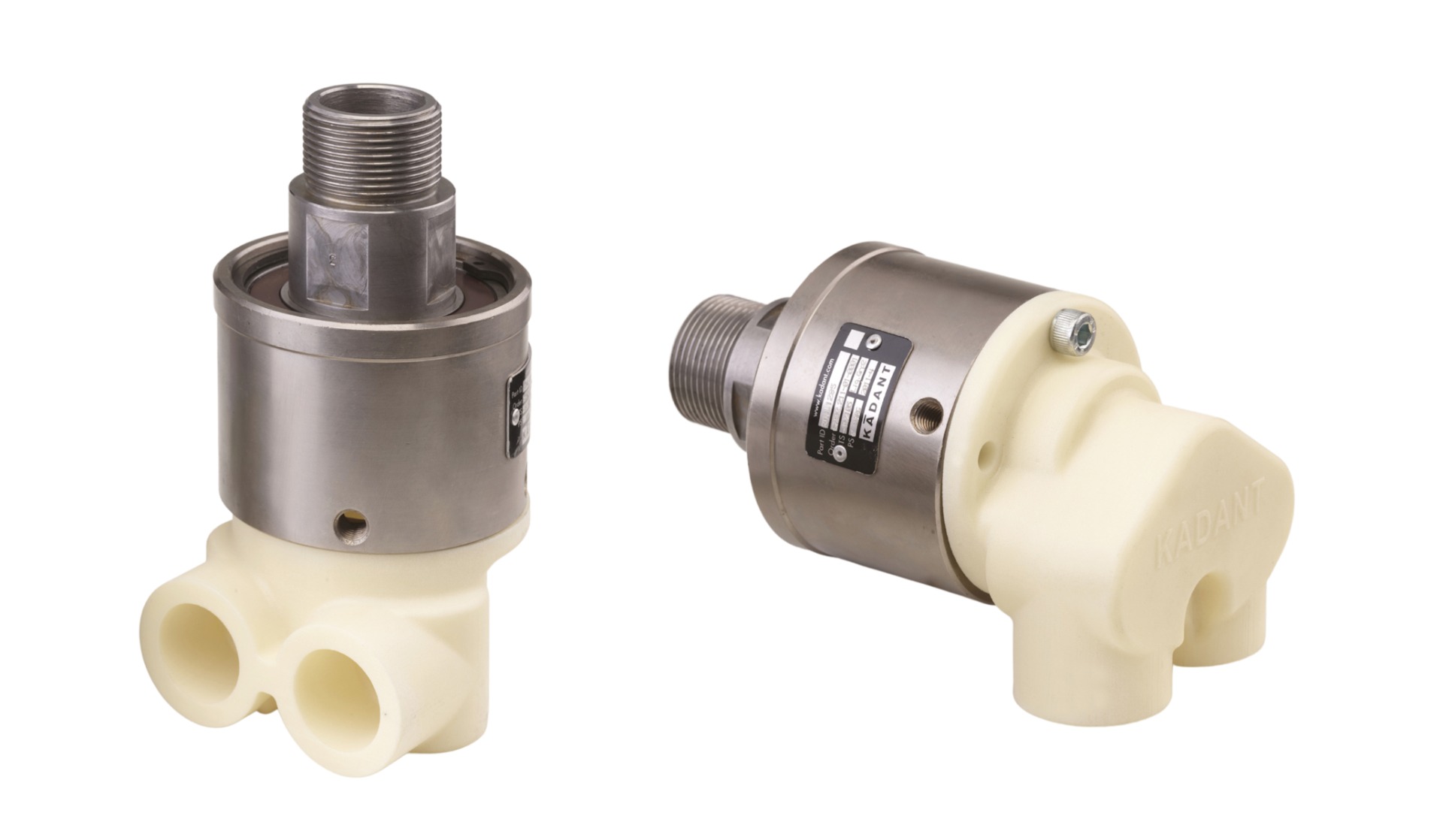

Unions with bearings have the advantage of having low friction, especially if mounted in set; this is a useful technical solution to eliminate some of the torque. In addition, their internal mechanical seal makes maintenance less frequent

The custom solution presented and embraced by the end customer

The custom solution presented and embraced by the end customer

A win-win strategy

The best part of using this kind of approach is that it is not based on theory but is proven by results in the real market: once we get our customers used to a "problem-solving service," they are unlikely to be satisfied with just selling a product...this is the strength of those who believe in and invest in providing real, long-term benefits to the customer.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091