When the going gets tough… reliable partners and efficient solutions are needed

How do you partner the industry leaders?

Competitiveness, speed, service and quality; this is Johnson-Fluiten's recipe for conquering the machine tool market. Let's find out why Porta Solutions chose Johnson-Fluiten as their single-source supplier for rotary joints

For 65 years, Porta Solutions has been offering customers real results, even before machine tools. Known and appreciated for its innovative CNC machining centres with three independent spindles, the Brescia-based company specialises in the design and implementation of production systems for mechanical engineering companies.

Porta Solutions machining centres guarantee shorter lead times and lower machining costs, an advantage that translates into greater efficiency and competitiveness.

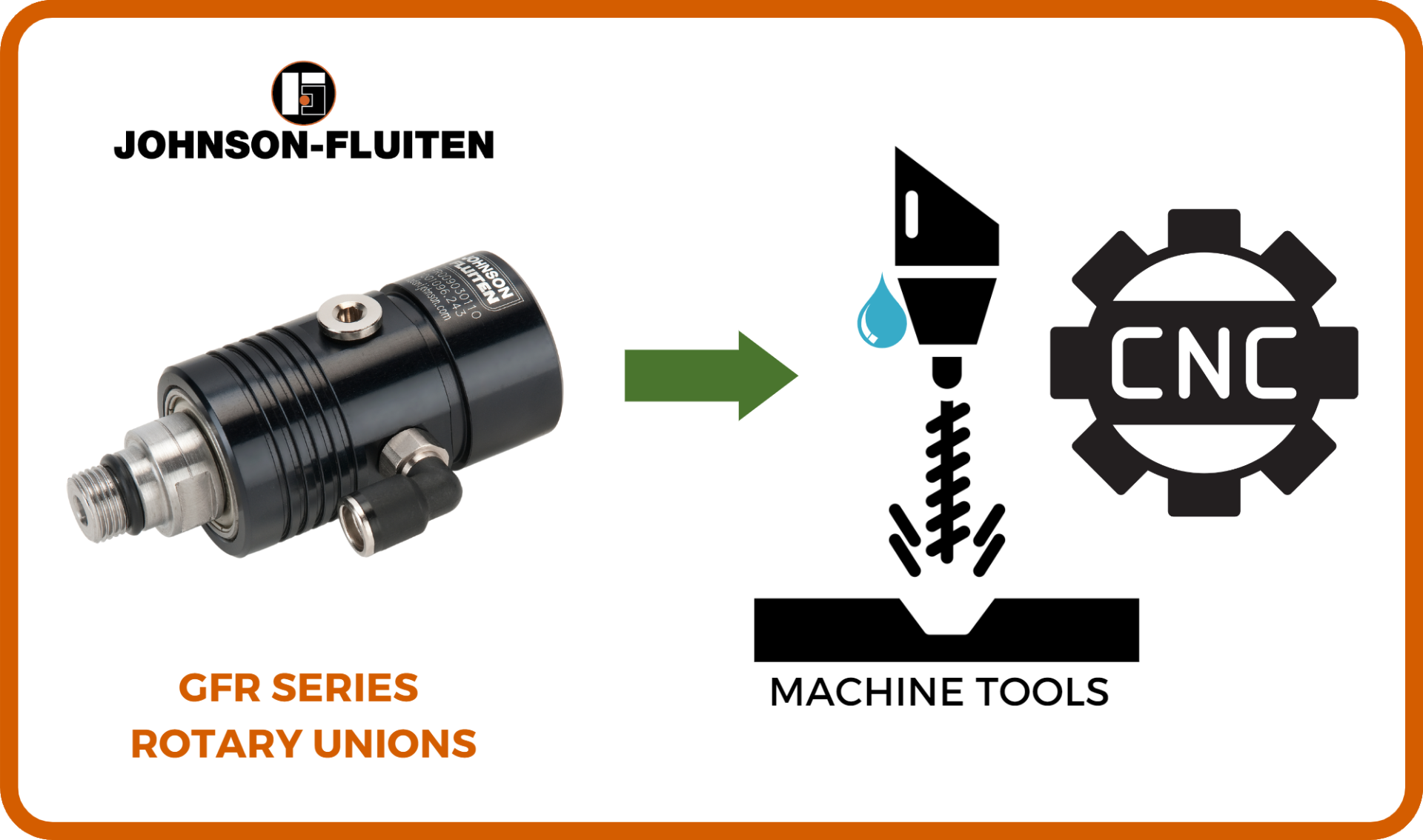

In order to guarantee customers a constant level of excellent performance, the best components available on the market must be used: when it comes to rotary joints, this means using Johnson-Fluiten solutions

Porta Solutions' independent three-spindle machining centres are on the market as three times more productive solutions than traditional machining centres: a statement that is easy to validate, if one considers that the presence of the three spindles allows for format changes or repairs without interrupting production. In short, companies with frequently changing productions and with medium or small batches, which are increasingly demanded by the market, can achieve the flexibility they would have with three or four separate machining centres in a much more compact space and at a very competitive cost.

Obviously, the construction and development of these machines involves considerable design work, and keeping these machining centres in perfect condition requires, among other things, an accurate and constant, maintenance-free and always completely reliable coolant system

When standards are high

Innovating means making unique and special things, which is why, when the engineers approached Johnson-Fluiten to find rotary joints to suit their needs, they were already prepared for the idea of having to have a customised component made.

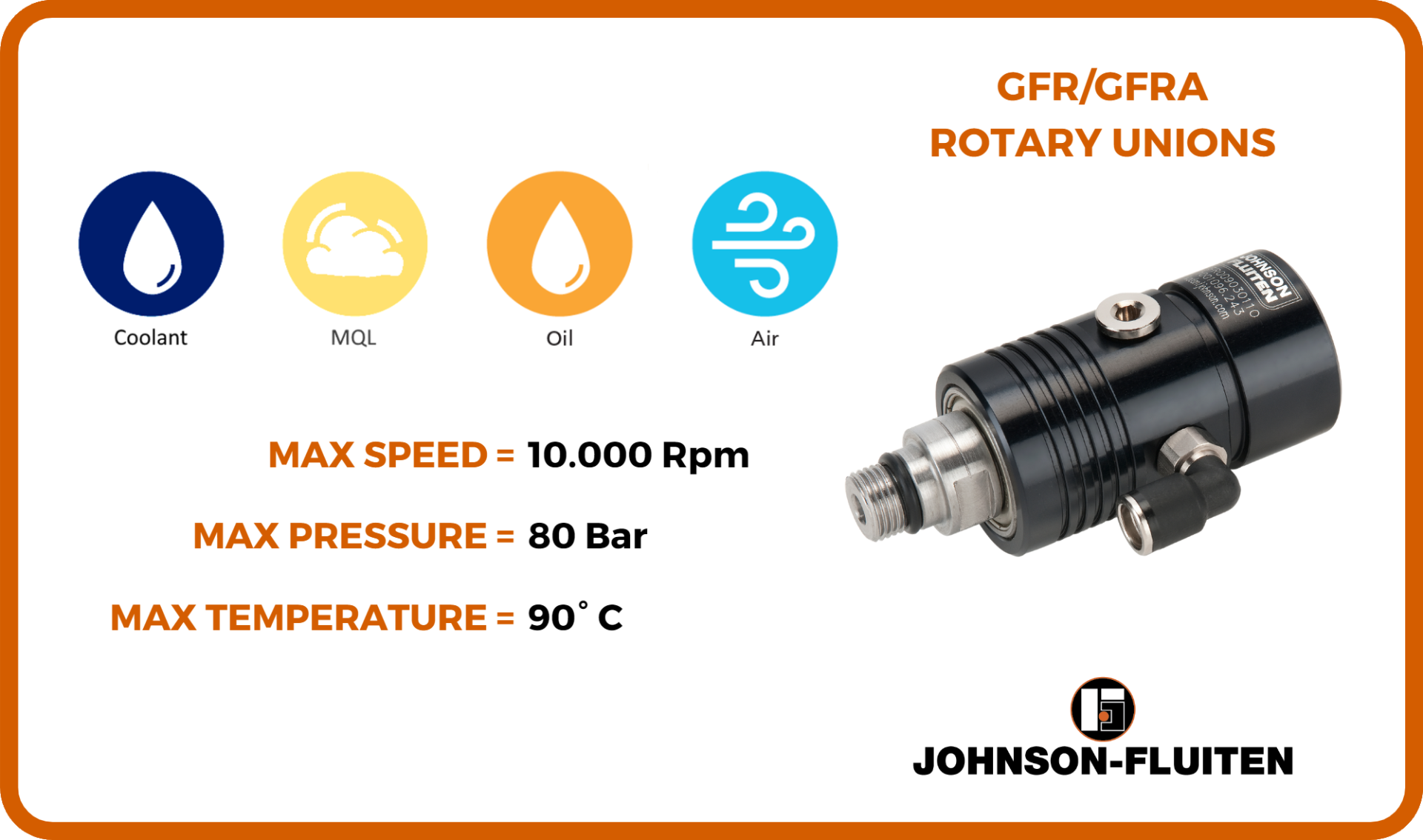

Johnson-Fluiten, a company that has been designing and manufacturing rotary joints for water, steam, oil and coolant applications for more than 20 years, is fully capable of producing tailor-made components when required, but the wide range of products in the catalogue combined with the experience and expertise of its engineers often allows it to identify solutions even for complex situations by selecting them from among the proposals already in the catalogue.

After carefully evaluating the requirements of this specific application, Johnson-Fluiten's highly qualified staff was able to come up with a standard G-Series rotary joint that was a perfect solution for these specific needs, with the added advantage of immediate availability, and therefore the possibility of immediate use, without having to wait for the design and prototyping phase to be completed.

The GFRA machine tool joints from Johnson-Fluiten are able to meet the high quality requirements of Porta Solution; and thanks to this, there was no need to choose a custom-designed component

When 'good' is not enough

The SERIE G rotary joint was immediately tested successfully, allowing the coolant to flow in the spindle axis, a necessary condition for smooth and constant operation of the production process.

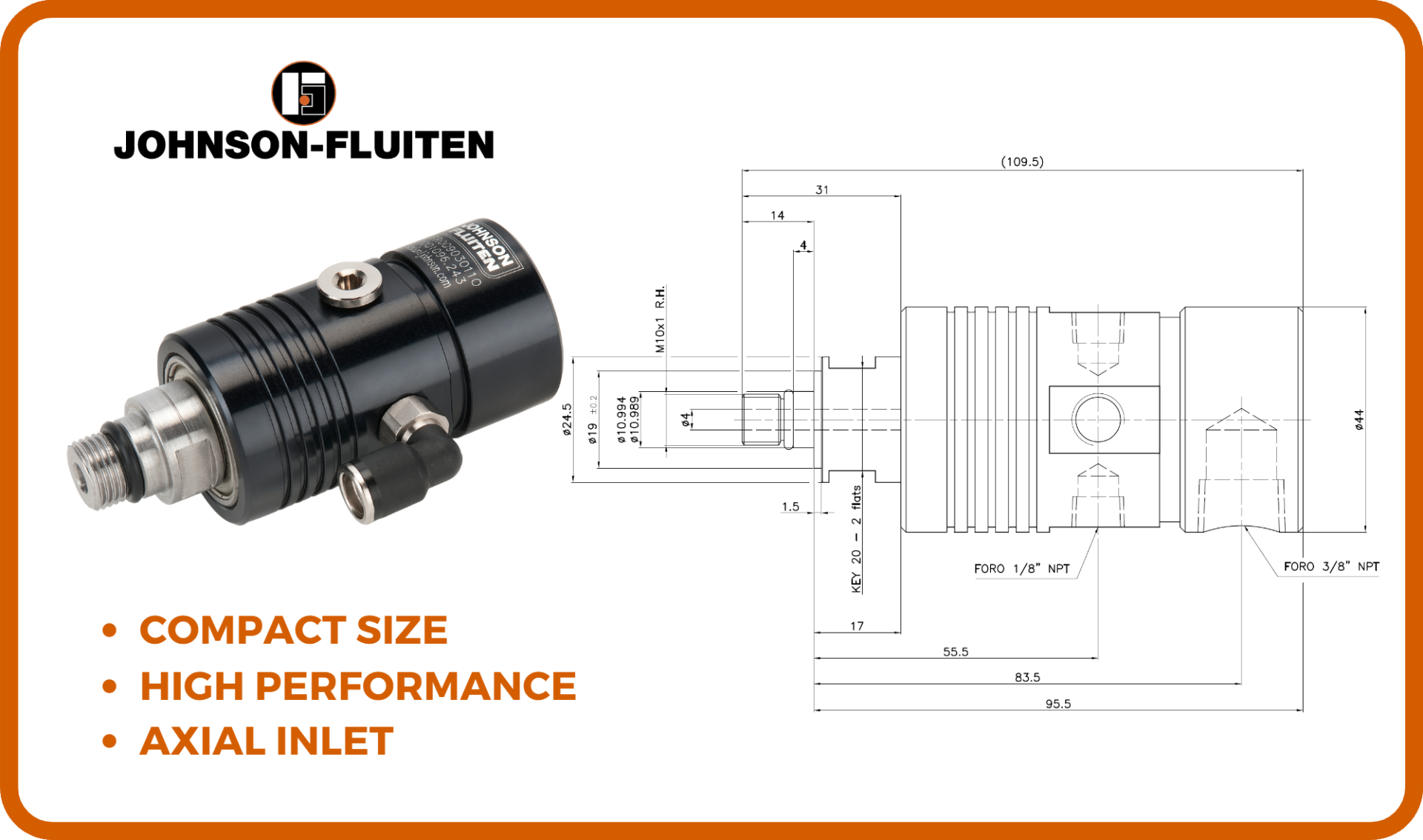

Everything is fine, then, but for Johnson-Fluiten 'fine' is not enough: the solution showed margins for improvement that were immediately identified and analysed. In particular, the type of rotary joint adopted, ideal for heavy-duty applications, proved to be sensitive to vibration due to its large size and weight. In order to guarantee the absolute operational reliability of the component, the Johnson-Fluiten engineers suggested a small improvement; the joint was therefore tied to a support, a solution that allowed the effect of vibrations to be totally attenuated.

Porta Solutions has been able to verify that Johnson-Fluiten's excellence service continues even after the product has been delivered, with the company's engineers fully willing to evaluate performance in the field and work together to improve it, until it reaches the levels of efficiency the customer expects.

Not customers but partners

The products and support provided convinced Porta Solutions to choose Johnson-Fluiten as their single-source partner for the supply of fluid handling components. Compared to the competitors, the advantages were many; especially significant was the ability to find a high quality standard solution without having to rely on customisation, which obviously had a positive impact on the overall cost of supply.

In addition, Porta Solutions has always found Johnson-Fluiten's technicians to be fully available to examine and understand requests, meet requirements and provide resolving technical advice, thanks to this supplier's obvious expertise in the joint segment.

Porta Solutions now joins the large ranks of leading companies that can confirm that Johnson-Fluiten is a supportive partner that is always sensitive to its customers' needs, from initial contact, through the quotation process, to delivery and beyond.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091