What are OTS (Over-The-Shaft) rotary joints designed for?

Discover the Modern Applications of OTS Rotary Unions

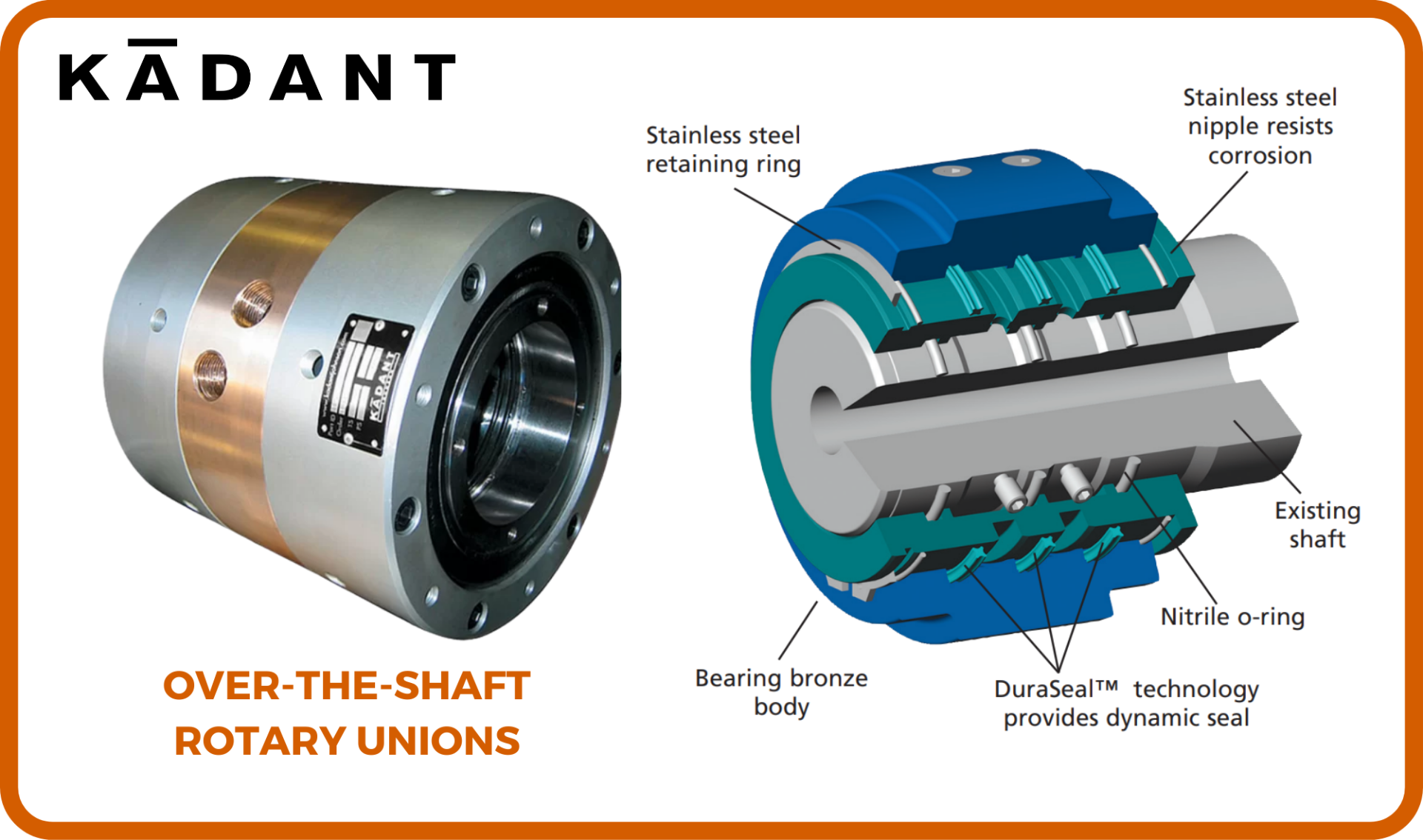

Over-the-shaft (OTS) rotary unions are the backbone of fluid conveyance systems, seamlessly integrating with journals (shafts) that facilitate the flow of liquids into and out of rolls. As the journal rotates, the OTS rotary union seals around it, enabling the smooth transfer of fluids through the channels. These ingenious devices find frequent use in situations where fluid conveyance and the drive system coexist at the same end of a roll. Such applications require the journal to convey fluids while simultaneously transferring torque. Traditionally, you'll find OTS rotary unions in the metal industry, where water cooling is paramount. However, their versatility shines in any scenario where water, steam, or other fluid transfer is essential

A Glimpse into the Inner Workings of OTS Rotary Unions

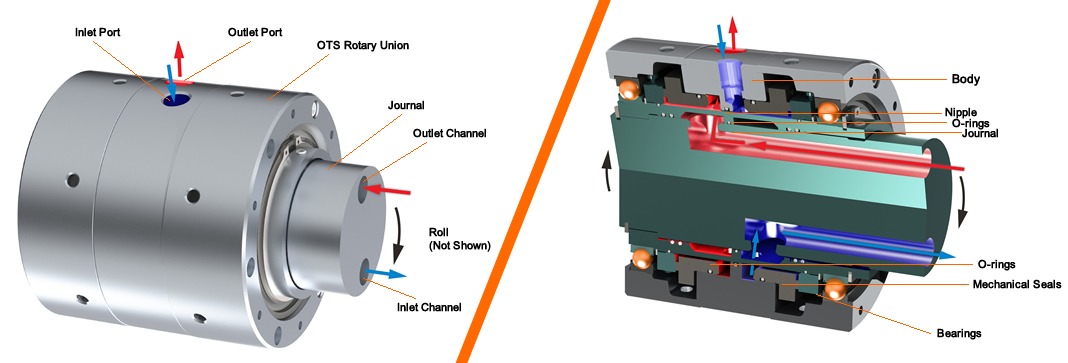

OTS rotary unions employ strategically positioned ports to manage the fluid flow within the journal's channels. The number of inlet and outlet ports is meticulously aligned with the number of channels. Adding ports elongates the OTS rotary union, ensuring an optimal fit for the specific application.

The installation process is straightforward: an OTS rotary union is carefully positioned over the customer's journal, with elastomeric rings forming a secure seal between an internal rotor and the journal. The rotor and journal subsequently operate as a single unit within the stationary housing, as shown in green. The sealing technology employed between the rotating rotor and the stationary housing is pivotal in ensuring a leak-free performance. Elastomeric seals are the preferred choice for most applications, while high-speed, high-wear scenarios benefit from balanced mechanical seals. Steam applications, on the other hand, employ pressure mechanical seals, resembling the design of balanced mechanical seals.

Selecting the Ideal OTS Rotary Union

The cornerstone of reliable, leak-free performance in OTS rotary unions lies in the seal technology they employ. At Kadant Johnson, we take pride in utilizing the cutting-edge DuraSeal™ high-performance elastomeric sealing technology, as well as proven mechanical seal designs. Our custom-designed OTS rotary unions are available in various sizes, configurations, and performance specifications tailored to the specific requirements of water, steam, and other fluid applications. Below, you'll find examples of typical configurations for water and steam scenarios:

Balanced Mechanical Seal OTS Rotary Union

- Applications: High-speed

- Pressure: 60 psig (4 bar)

- Temperature: 150°F (66°C)

- Rotation Speed: Up to 200 RPM

- Media: Water

- Passages: 1 to multiple

- Sealing Technology: Balanced mechanical & DuraSeal

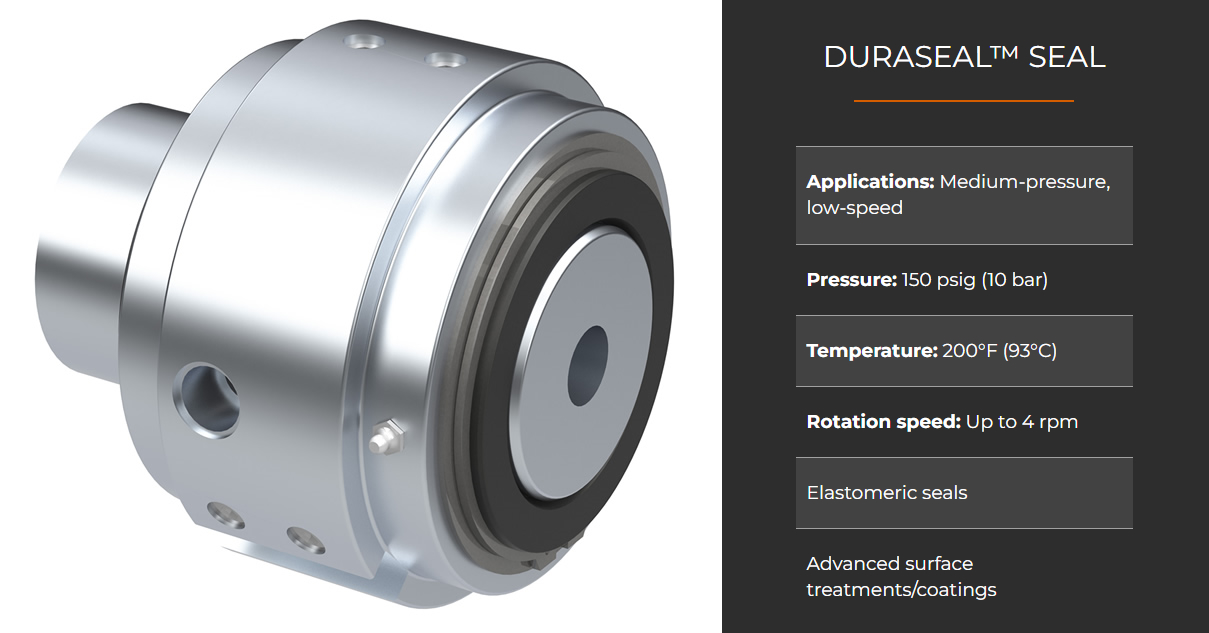

DuraSeal OTS Rotary Union

- Applications: Low-speed

- Pressure: 150 psig (10 bar)

- Temperature: 200°F (93°C)

- Rotation Speed: Up to 4 RPM

- Media: Water

- Passages: 1 to multiple

- Sealing Technology: DuraSeal

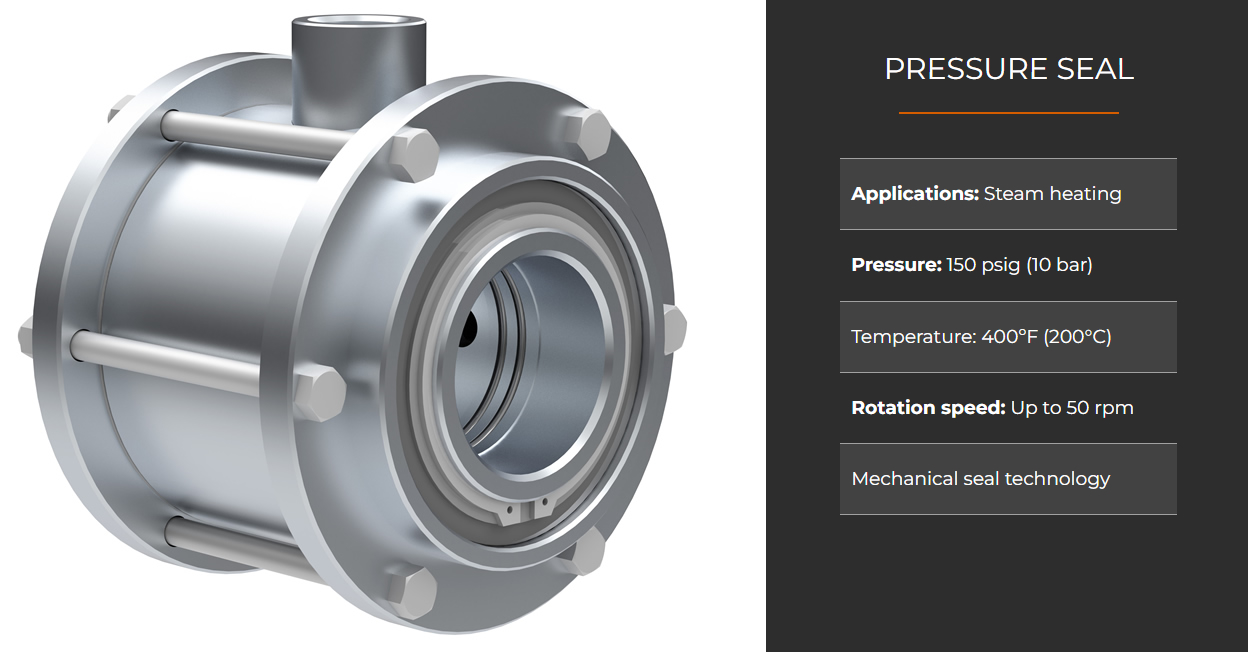

Mechanical pressure seal OTS Rotary Union

- Applications: Moderate-speed

- Pressure: 150 psig (10 bar)

- Temperature: 400°F (200°C)

- Rotation Speed: Up to 50 RPM

- Media: Steam

- Passages: 1 to multiple

- Sealing Technology: Pressure mechanical seal

Elevate your fluid conveyance systems with Kadant Johnson's state-of-the-art OTS rotary unions, designed for optimum performance and efficiency. Get in touch with us today to explore how our cutting-edge technology can transform your fluid management processes.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091