PAPER AND CARDBOARD MILLS

PAPER AND CARDBOARD MILLSIn the paper and cardboard industry, rotary joints play a vital role in multiple stages of paper production and recycling, increasing process efficiency and finished product quality. The rotary joints offered by Kadant and marketed by Johnson-Fluiten are designed to optimise energy consumption and improve water & steam management, thus contributing to long-term environmental sustainability.

Specific applications in the paper industry include using rotary joints for dryer rolls and calenders, which are also essential for preheating and corrugating paper in corrugating machines. They are also used in converting processes, such as flexographic printing, calendering and cooling, where precision and efficiency are paramount.

To provide comprehensive support to customers in the paper and board industry, Kadant also offers a wide range of catalogue products, with solutions tailored to each specific requirement. These components are designed to withstand extreme operating conditions, such as high temperatures and pressures, ensuring reliability and durability. This flexibility and specialisation make Kadant and similar suppliers an ideal partner for the needs of the paper and board industry, providing innovative and efficient solutions for fluid transfer in complex production environments

RELATED PRODUCTS

|

|

|

|

|

|

|

LEARN MORE IN OUR ARTICLES

- WHY ARE TURBULATOR BARS IMPORTANT IN THE PAPER DRYING PROCESS

- EFFICIENCY, SAVINGS AND SAFETY. 3 CUSTOMER VALUES EXPLAINED BY 3 PROFESSIONALS

- HOW TO MAXIMIZE THE DURABILITY AND PERFORMANCE OF ROTARY JOINTS?

- CARBON FIBRE GUIDES OR BALL BEARINGS?

- "QUALITY IS MEASURED OVER TIME" - THE CASE STUDY FOR OUR ROTARY JOINT RECONDITIONING SERVICE

- THE BEST SOLUTIONS TO THE CORRUGATED MARKET.

RUBBER AND PLASTIC

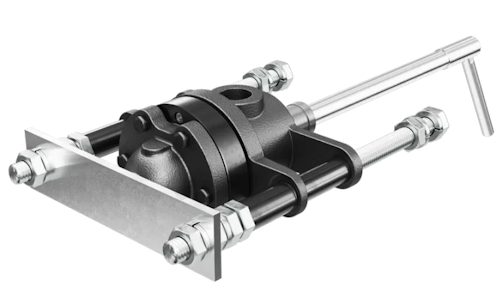

RUBBER AND PLASTICIn the rubber and plastics industry, Johnson-Fluiten rotary unions play a vital role, facilitating mixing and extrusion applications for the production of rubber products. These components are essential in rubber processing where fluids (such as water, oil or steam) need to be transferred from a stationary source to rotating moving parts.

In the plastics industry, rotary joints are used in heating and cooling systems, as well as in moulding applications, where maintaining exact temperature control is critical. They are an integral part of extrusion lines for the production of plastic films, including blown film, stretch film and bubble film, as well as converting machines.

Operational efficiency is vital in these industries, where reducing downtime and saving energy are top priorities. Johnson-Fluiten is committed to using the latest technology and continuous innovation and research to optimise customers' production processes. Rotary joints are designed for maximum reliability and durability, while reducing energy costs and improving overall production efficiency.

Through constant innovation, Johnson-Fluiten ranks as a leading provider of fluid handling solutions, offering products that meet the specific needs of the rubber and plastics industries. This translates into direct support for customers to make their production processes more efficient and sustainable, highlighting the crucial role of rotary joints in a wide range of industrial applications.

RELATED PRODUCTS

|

- ROTARY UNIONS R |

|

|

|

|

|

- KADANT ELSX |

|

LEARN MORE IN OUR ARTICLES

- HOW TO WIN THE CHALLENGE OF CUSTOMIZED PRODUCTION

- WHAT TO DO IF THE COMPONENTS YOU ARE USING GO OUT OF PRODUCTION?

- INNOVATING TO EXCEED LIMITS: NEW CALENDERING FRONTIERS

- THE BEST COMPONENTS FOR RUBBER, PLASTIC AND PVC PROCESSING PLANTS

- HOW TO INCREASE THE EFFICIENCY OF A PVC PROCESSING PLANT WITH ELS SERIES ROTARY JOINTS

- WHAT IS QUICK REPLACEMENT DESIGN (QRD)

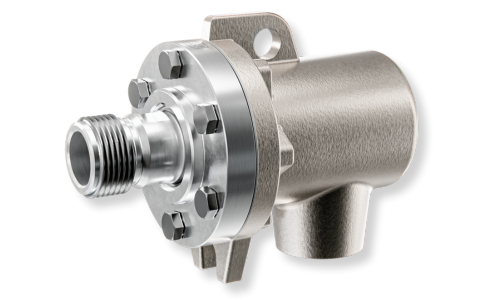

FOOD & BEVERAGES

FOOD & BEVERAGESIn the food industry, Johnson-Fluiten rotary joints are used in a variety of processes including drying, mixing, packaging, heating and cooling. These components are essential to ensure the efficient and safe transfer of fluids such as steam, water, thermal oil, refrigerant and hydraulic oil between stationary piping and moving equipment. The ability to handle multiple fluids simultaneously through multi-pass couplings is an appreciated feature in these applications.

In addition, rotary joints are designed to meet the high quality standards required in the food industry, including compliance with FDA and ATEX certifications to ensure safety in food production processes. Versions made of stainless steel are particularly suitable for use in the food industry due to their corrosion resistance and ease of cleaning.

Specific applications in the food industry include use in mixers, cookers and fillers, where rotary joints must operate with precision to ensure product integrity during production. Customising products to suit specific needs is another key aspect that Johnson-Fluiten offers its customers, ensuring that each component can be seamlessly integrated into existing systems.

RELATED PRODUCTS

|

|

|

|

|

|

|

LEARN MORE IN OUR ARTICLES

CHEMICAL AND PHARMACEUTICAL

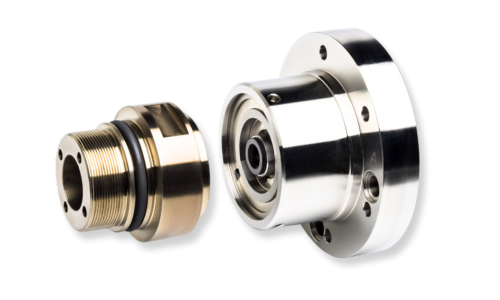

CHEMICAL AND PHARMACEUTICALJohnson-Fluiten rotary joints find critical use in the chemical and pharmaceutical industries, where precision and reliability are of top priority. These devices are essential for mixing and transferring fluids such as thermal oil, water and glycol, and in some cases, nitrogen. Particularly in the pharmaceutical industries, which operate with strict requirements for cleanliness and sterilisation, rotary joint solutions must guarantee flawless operation.

Specialised versions of Johnson-Fluiten rotary joints, such as those made of Hastelloy C22, offer corrosion resistance and are suitable for handling the aggressive media often encountered in these environments. These advanced materials are essential for applications requiring high product purity and superior chemical resistance.

For the pharmaceutical industry in particular, Johnson-Fluiten designs high-speed rotary joints for centrifuges and solid-liquid separation applications. These applications require rotary joints that can handle high speeds and centrifugal forces while maintaining seal integrity and ensuring product purity.

Constant innovation and research enable Johnson-Fluiten to provide highly specialised and reliable solutions that meet the specific needs of these advanced industries, supporting companies in achieving optimal production efficiency and adherence to safety and quality regulations. Such as ATX or FDA

RELATED PRODUCTS

|

|

|

|

|

|

|

LEARN MORE IN OUR ARTICLES

METAL - STEEL PRODUCTION

METAL - STEEL PRODUCTION In the steel industry, Johnson-Fluiten rotary joints are a crucial component, being used in a wide range of heavy industrial processes, such as casting, casting, hot and cold rolling, extrusion, and galvanising processes. These joints are strategically installed inside bearing covers to protect them from environmental damage, a design decision that ensures greater durability and ease of maintenance.

The use of rotary joints in ovens and cooling chambers is equally critical, as these environments impose extreme operating conditions where it is critical to maintain the integrity of fluid transfer in the face of high temperatures and abrasive conditions. These rotary joints are designed to withstand not only high temperatures but also mechanical and chemical stresses, thus ensuring safe and reliable transfer of water and other fluids required for cooling and thermal control of processes.

To summarise, Johnson-Fluiten's technological expertise in the field of rotary joints translates into solutions that support the steel industry in addressing its unique challenges, improving operational sustainability and helping to reduce environmental impact through more efficient and less energy-intensive processes.

RELATED PRODUCTS

|

|

|

|

|

LEARN MORE IN OUR ARTICLES

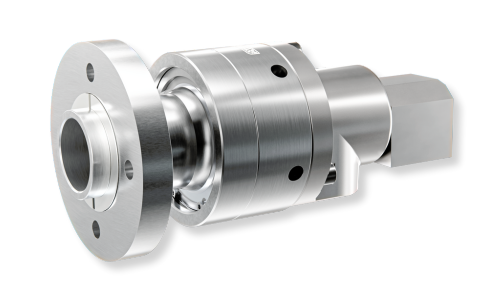

MACHINE TOOLS

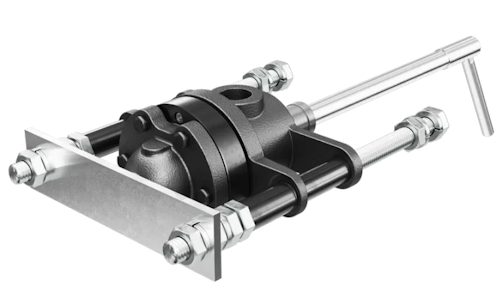

MACHINE TOOLS Johnson-Fluiten rotary joints are essential in the machine tool industry, where high precision and reliability are non-negotiable requirements. These devices are designed for applications requiring high-speed operation, uniform rotation and handling of fluids such as coolants, air and hydraulic oil. They are used in a wide range of machinery including transfer lines, drills, drilling machines, milling machines, CNC spindles, rotary tables and many others.

Johnson-Fluiten's G series, for example, was developed specifically to meet the needs of high-speed machine tools, being able to reach up to 50,000 rpm and handle pressures up to 400 Barg (approx. 5800 psi). These rotary joints are compatible with a wide range of fluids, proving to be versatile and adaptable to different industry requirements. Their compact size and option for both axial and radial inlets offer installation flexibility and less stress on machine components, helping to improve overall efficiency and reduce operating costs.

Johnson-Fluiten also offers customisation of rotary joints to meet specific customer requirements, with the option of customising existing joints or producing new versions on request. Standard versions are capable of operating under extreme pressure and speed conditions, and are tested to ensure the highest quality before shipment.

RELATED PRODUCTS

|

|

|

|

|

LEARN MORE IN OUR ARTICLES

- WHAT ARE THE BEST SOLUTIONS FOR MANAGING FLUIDS IN SPINDLES?

- WHEN THE GOING GETS TOUGH…

- FROM CUSTOMER TO LONG-TERM PARTNER; THE EMPHASIS ON TRUE PRODUCT AND SERVICE QUALITY

- ROTARY JOINTS FOR MACHINE TOOLS: HIGH SPEED AND FULL ADAPTABILITY

- MACHINE TOOLS; JOHNSON-FLUITEN'S SOLUTION FOR THE WORKHEAD SPINDLE

TEXTILES / NON-WOVENS

TEXTILES / NON-WOVENSIn the textile and nonwovens industry, Johnson-Fluiten rotary joints play a crucial role in the entire production process, from the initial fibre formation stage, through stretching operations, to the final finishing stage. These specialised solutions not only increase the efficiency of production processes, but also help reduce energy costs.

Specific applications in the textile and non-woven industry include converting, laminating and coating, as well as the production of synthetic fibres, where rotary joints are used for the optimal transfer of fluids such as water, thermal oil and coolants in machinery requiring high precision and reliability. Johnson-Fluiten offers a variety of rotary joints that can be customised to meet specific needs, ensuring solutions that perfectly match customer requirements. Our rotary joints are designed for applications requiring high speed, high pressure and high temperature, and also for dry testing.

RELATED PRODUCTS

|

|

|

|

|

|

|

- KADANT SX |

LEARN MORE IN OUR ARTICLES

ENERGY

ENERGYRotary joint technology is essential in the energy sector, where reliability and operational efficiency are crucial. Johnson-Fluiten rotary joints are used in a wide range of activities, from drilling to oil and gas production and distribution, where safety and quality are imperative.

Customised Johnson-Fluiten rotary joints are designed to meet specific needs, such as handling high-pressure and high-speed fluids, which are characteristic of Kaplan turbine energy production. Our offer includes comprehensive support in the development of customised solutions, guaranteeing the highest level of technical service thanks to our in-depth knowledge and experience in the energy sector.

Our commitment is to provide solutions that integrate seamlessly with existing infrastructure, promoting innovation and sustainability. The focus on safety, reliability and efficiency makes Johnson-Fluiten rotary joints the ideal partner for energy industries with a focus on resilience and operational adaptability in any environment.

With Johnson-Fluiten, customers in the energy sector can count on a range of products that raise the standards of performance and safety, supported by a team of specialists ready to respond to any technical requirement. We are dedicated to constantly improving our technologies to maintain our position as a leader in fluid handling solutions and target markets, driven by innovation and a passion for excellence

RELATED PRODUCTS

|

LEARN MORE IN OUR ARTICLES