A SUCCESS STORY IN FOOD INDUSTRY SOLUTIONS THANKS TO JOHNSON-FLUITEN COMPONENTS

A partnership that has lasted for decades: the partnership between Boema, a major manufacturer of equipment for the food industry, and Johnson-Fluiten, a company focused on the design and production of rotary joints, owes its longevity to a shared emphasis on quality, but above all to the ability to meet challenges by finding the best solution thanks to expertise and know-how.

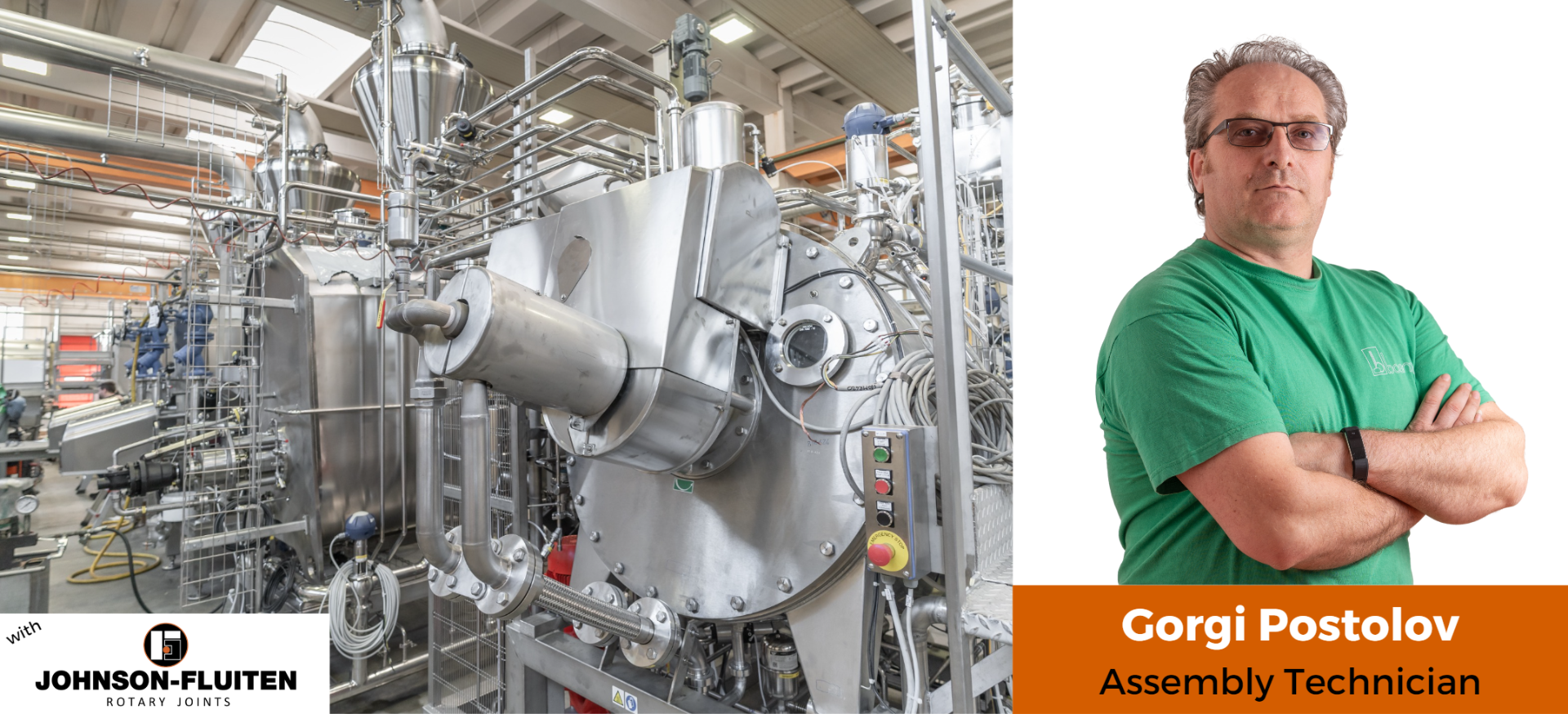

For over forty years, Boema has been known by customers all over the world for its systems for the food industry. The constant evolution of the solutions taken to be ahead of processing techniques has allowed Boema to grow and become an international company with more than 220 employees and production facilities occupying a total of 23,000 square metres of covered area. The Boema plants installed worldwide have now exceeded 1500.

One of Boema's strengths is the workshop where it produces almost all the components it uses in its plants, using state-of-the-art machines and tools capable of performing complex machining operations, from laser cutting to turning and milling large parts.

As the company is strongly focused on maintaining total quality control at every stage of the production process, it is clear that the components it purchases from third parties must meet extremely high quality standards. One of these strategic partners is Johnson-Fluiten, Milan-based company specialising in the design and production of solutions for water, steam, oil and coolant applications.

We asked Gorgi Postolov, Assembly Transfer Technician, to describe the relationship between the company and this supplier.

How long have you been using Johnson-Fluiten rotary joints and for which reasons?

<< We are proud to say that our company has chosen Fluiten, and later Johnson-Fluiten, as its rotary joint supplier for over 30 years.

Johnson-Fluiten is an Italian company with a long history of excellence in the design and manufacture of rotary joints for industrial applications. Their knowledge and expertise are shown in the quality of their products. We chose Johnson-Fluiten as our steam and water rotary joint supplier because their products are reliable, high-quality, customisable and customer-oriented. We are grateful for their cooperation and look forward to continuing to work together. >>

What features of Johnson-Fluiten's offering did you appreciate the most?

<<We chose Johnson-Fluiten because they offered us a range of high-quality products that met our specific needs. We appreciated their ability to customise products to our specific design requirements.

In particular, we trusted Johnson Fluiten because their rotary joints are reliable, durable and easy to maintain. They are designed to withstand high temperatures, high pressures and the most extreme working conditions, ensuring maximum efficiency and safety. The BOEMA production plant for jam/sauce or the system for the production of sterile preparations use equipment that is made up of a mixer with an interior rotary heat-exchanger. The chosen rotary joints must operate efficiently and reliably. BOEMA mounts rotary joints for both steam and water application at the ends of its rotating bubble coils, which operate at high temperatures and pressures.>>

What kind of pre-sales and after-sales support did Johnson-Fluiten provide you?

<<We consider Johnson-Fluiten to be a reliable and customer-oriented partner. Their customer service was always ready to answer our questions and provided us with immediate technical assistance and support when needed. We feel supported and confident that we are dealing with a company that truly cares about customer satisfaction.>>

When difficulties appear, by working together we always find a solution

Supporting this statement, we can quote a real-life case in which Johnson-Fluiten support was crucial in solving a technical problem that allowed the company to optimise the design of one of its jam-making machines at a major European manufacturer.

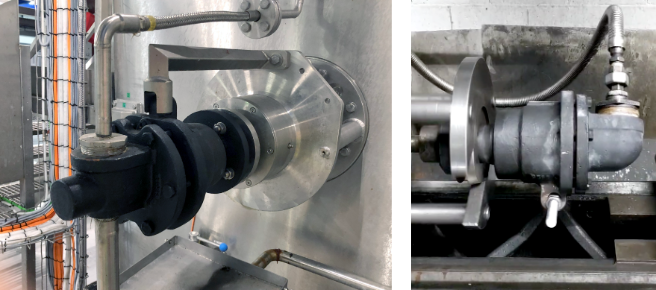

After the delivery of a machine to a customer in Northern Europe, reports came in of loud noises from the supplied rotary joint. Offering an outstanding after-sales service, Johnson-Fluiten engineers immediately went to the site and analysed the situation, surveying the component in operation.

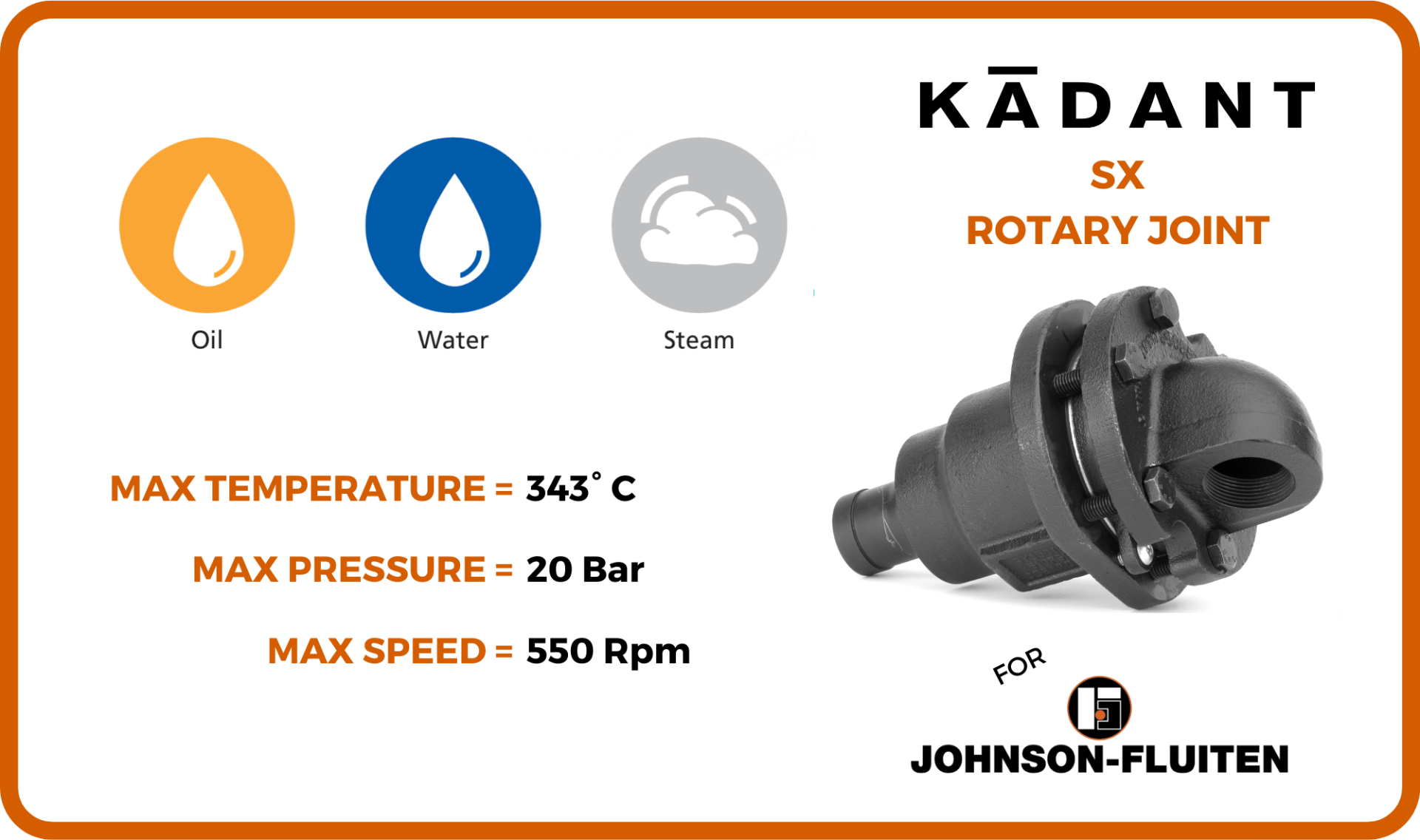

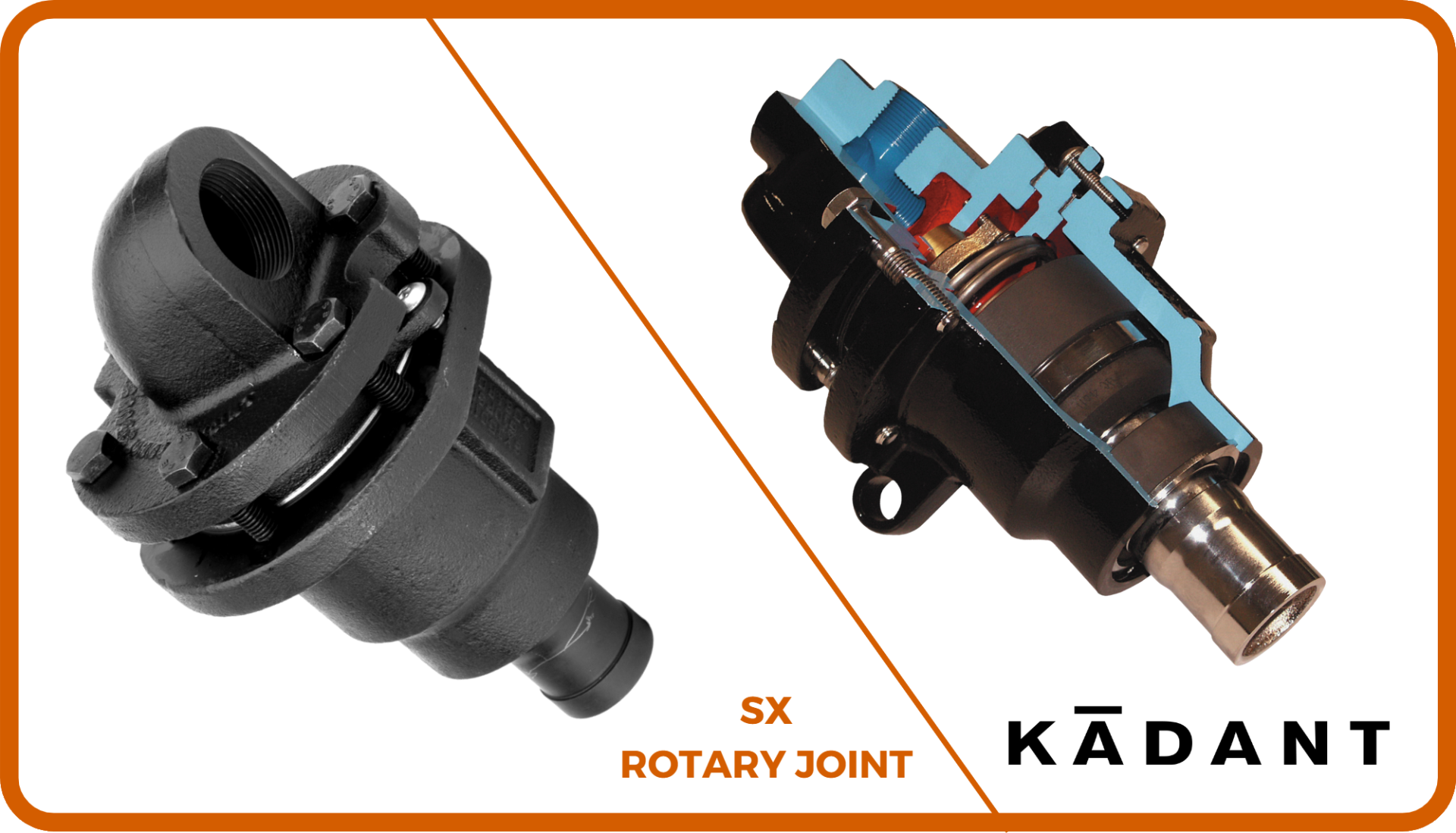

The SX-Series rotary joint by KADANT that was supplied for the application is normally used in steam, water and hot oil handling processes and is equipped with carbon-graphite bearings that allow automatic alignment and ensure a long service life even when installed on non-concentric cylinders.

After a careful inspection of the condition of the rotary joint, it was immediately possible to identify the cause of the component's sub-optimal operation; an incorrect assembly of the end customer's part. The rotary joint appeared to be completely fixed in place, without the slightest possibility of movement; in addition, it had to support the weight of 1.5 metres of rigid piping, which put the seal under extraordinary stress.

The unusual wear of the component was therefore due to factors unrelated to the product; but this did not stop the Johnson-Fluiten engineers who, after careful analysis of the application, suggested a different assembly to allow the rotary joint itself to perform its movements freely.

Then, after changing the rotary joint cartridge and restoring the component's perfect functionality, Johnson-Fluiten engineers provided design instructions to modify the design of the machine part:

-

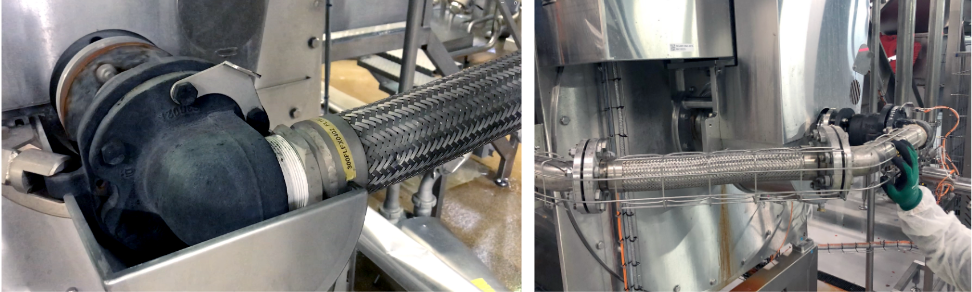

1 - Replacing a fixed pipe connected to the joint with a flexible one

-

2 - Changing the design of the anti-rotation support to increase the movement of the joint

-

3 - Modify the support to allow the bracket to only act as a contrast to the rotation and leave the rotary joint free to slide axially

The suggested modifications made it possible to reduce the strain and weight on the rotary joint, which could not work at its best with such forces.

Thanks to these solutions, it was possible to significantly improve the efficiency of the system in the long term, saving the end customer time and, above all, money.

A glimpse into the future

"The work done has certainly created a relationship of mutual trust and excellent synergy between our companies. Certainly in the future, the development of customisable joints and tailor-made solutions for special projects will form the basis of the two companies' cooperation.

A leading company must always be on the lookout for opportunities to develop new technologies and improve products, and Boema is confident that a collaboration with Johnson-Fluiten could provide further opportunities for growth and development"

Gorgi Postolov, Assembly technician

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091