How to handle the simultaneous transfer of different fluids? Multi-passage rotary joints from Johnson-Fluiten are the solution.

What are multi-pass rotary joints

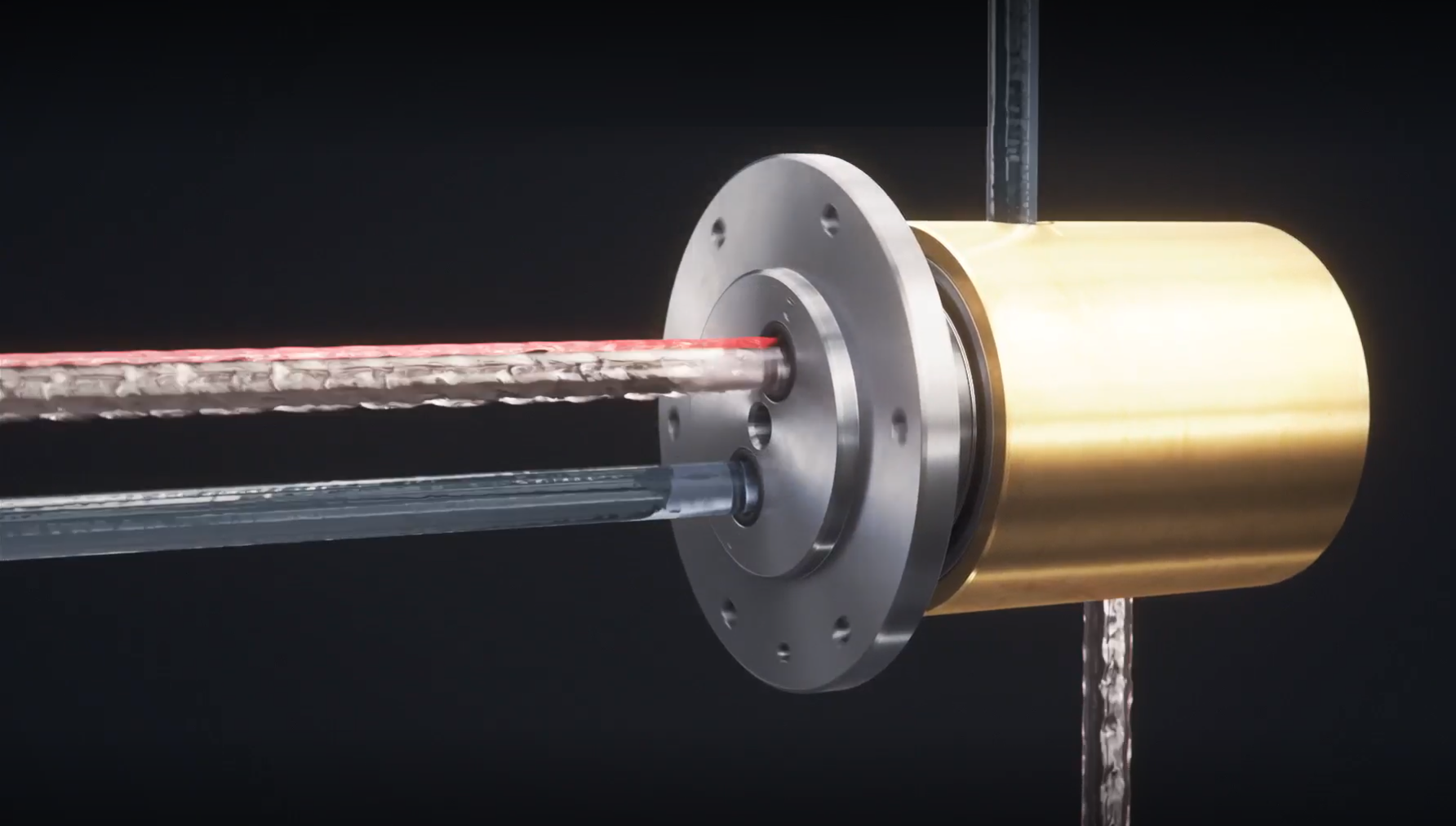

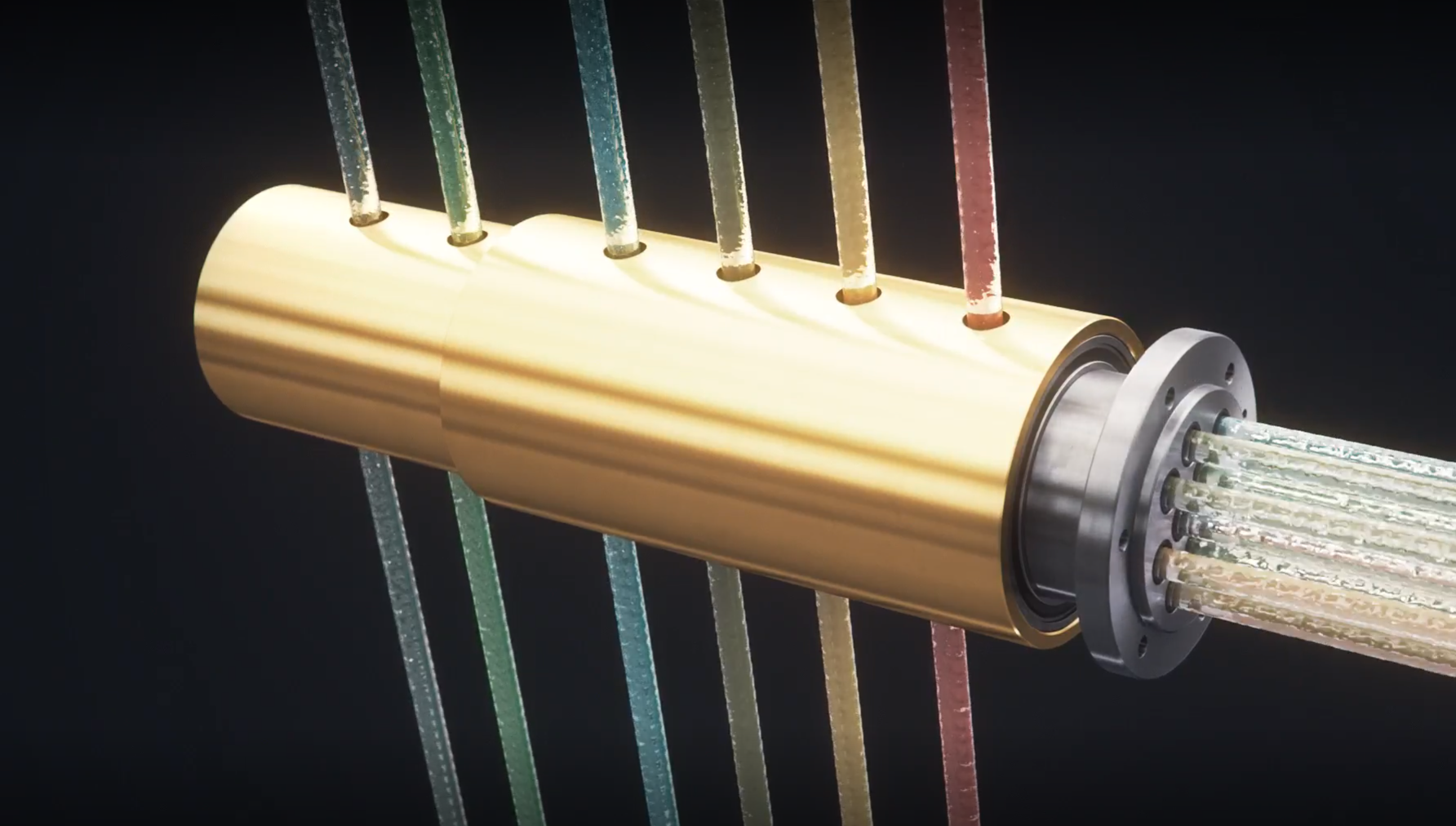

Multi-passage rotary joints are essential components for systems that require transferring different fluids or needing multiple passages sealed independently during rotation. They are designed to ensure no leakage and that pressure is maintained in each passage.

In some industrial applications, it is necessary to transfer 2 or more fluids (e.g. air and hydraulic oil) at the same time, which must not come into direct contact, and these rotary joints are the practical solution to this problem.

But how do these products work? How are they manufactured? And what are the factors to consider when choosing the best multi-pass coupling? Let's find out more about these Johnson-Fluiten products made in Italy.

How they are made

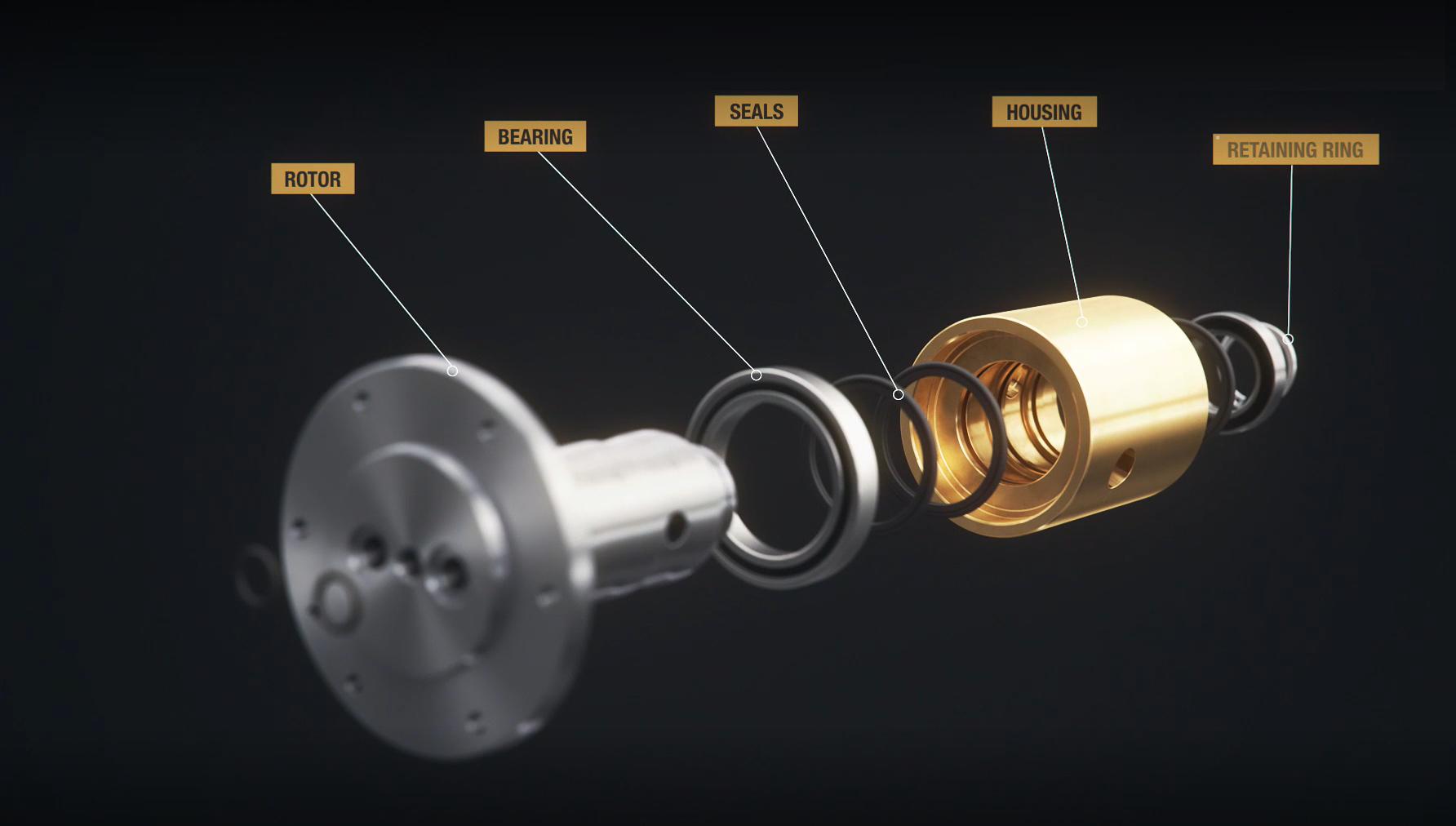

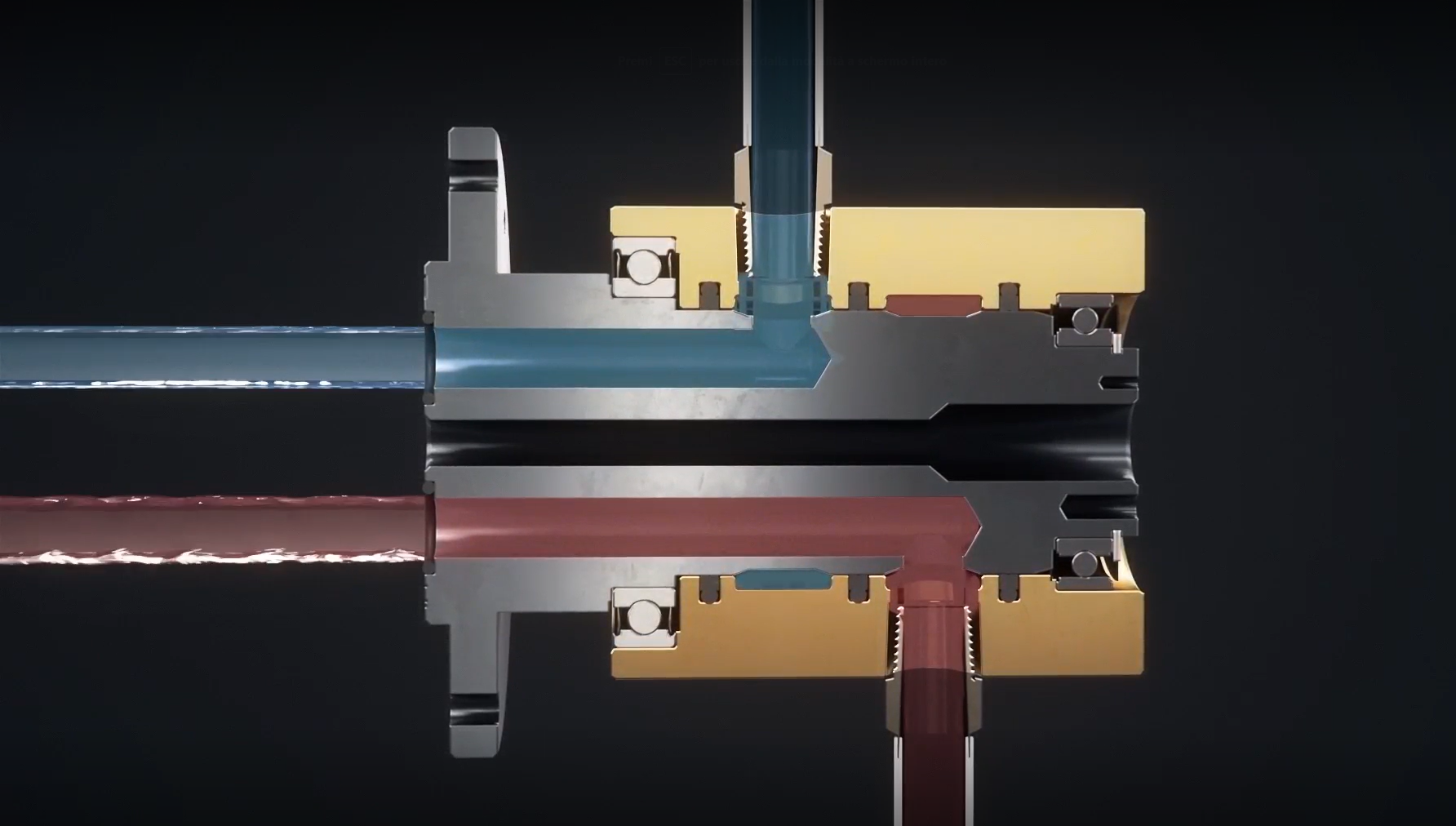

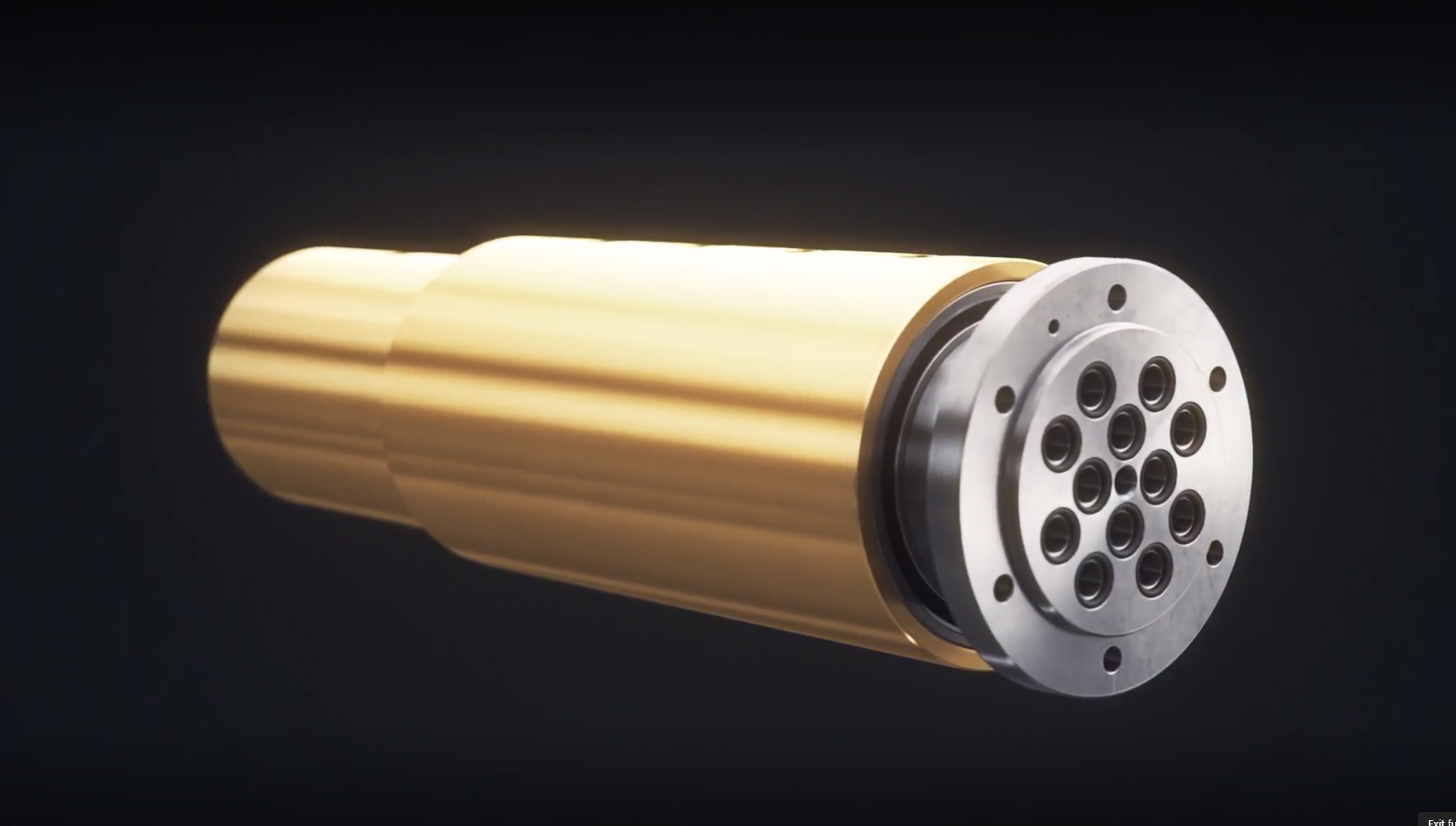

A multi-pass rotary union is made of the normal components of a rotary union such as the rotor, guides (or bearings), gaskets, body and seal. These components are integrated into the joint body, which is designed to provide separate passages for the transfer of different fluids, and it is possible to handle up to 12 individual passages in one joint. Moving fluids are separated by seals between the rotor and housing to ensure no leakage.

The Benefits

An advantage of rotary multi-passage joints is that they can rotate in both directions and the fluid can travel in any direction. The number of passages and the types of fluid that can flow through them are limited only by the size of the rotary joint. The design of separate channels allows the fluid to flow in any combination of directions.

What to look at

When choosing a multi-passage rotary joint, it is essential to consider factors such as; the type of fluid (or fluids) to be transferred, the choice of materials and seal technology, the required flow rate they must have, and above all the design that must be suitable for the specific application are the key elements to achieve reliable performance and avoid leakage.

Why choose our multi-pass rotary unions

To guarantee the highest possible performance, Johnson-Fluiten rotary joints feature a rotor made with a specific heat treatment that provides high strength in the sealing area. The rotor of our multi-pass unions is mounted on lifetime-lubricated ball bearings that ensure smooth, vibration-free operation. The sealing is realised with specially designed seals that guarantee extraordinary durability as well as the possibility of dry running.

In short

Multi-pass rotary joints allow independent flows to be kept separate. The main features of our STANDARD products are:

-

- suitable for air and hydraulic oil

-

- with precision ball bearings lubricated for life

-

- the unique 'sliding' seal guarantees long lifetime as well as dry running

-

- the stainless steel rotor is heat-treated (hardened)

-

- drain holes can be connected to a drain line

-

- products designed for multi-station rotary tables

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091