THE BEST COMPONENTS FOR RUBBER, PLASTIC AND PVC PROCESSING PLANTS

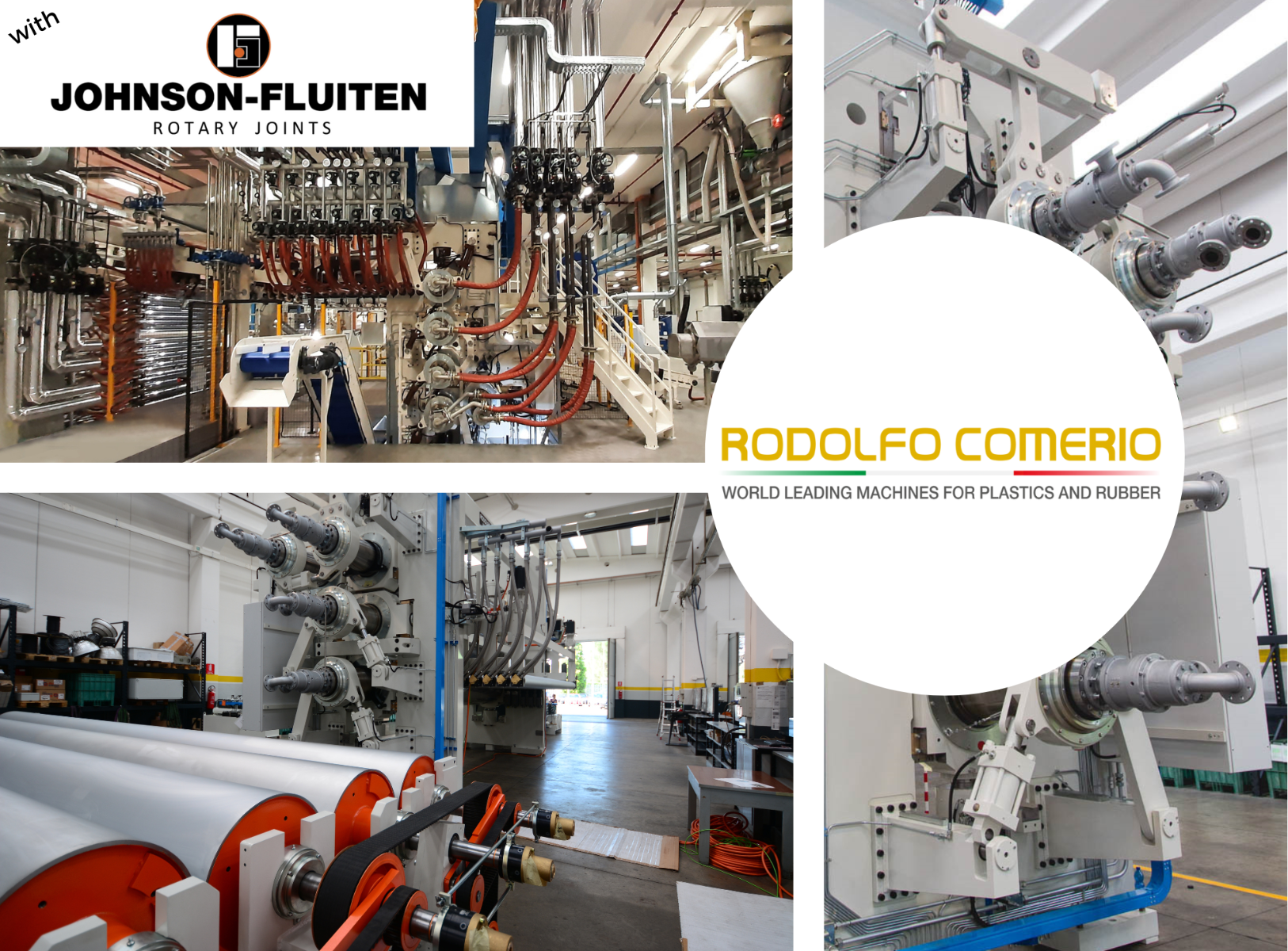

WITH 145 YEARS OF EXPERTISE IN THE ENGINEERING AND MANUFACTURING OF INDUSTRIAL SYSTEMS, RODOLFO COMERIO HAS BECOME A LEADER IN THE RUBBER AND PLASTICS EQUIPMENT SECTOR THROUGH TECHNOLOGY AND INNOVATION. THEIR HIGH QUALITY STANDARDS ARE REFLECTED IN THEIR CHOICE OF COMPONENTS: INCLUDING OF COURSE THE ROTARY JOINTS, FOR WHICH THE COMPANY RELIES ON JOHNSON-FLUITEN.

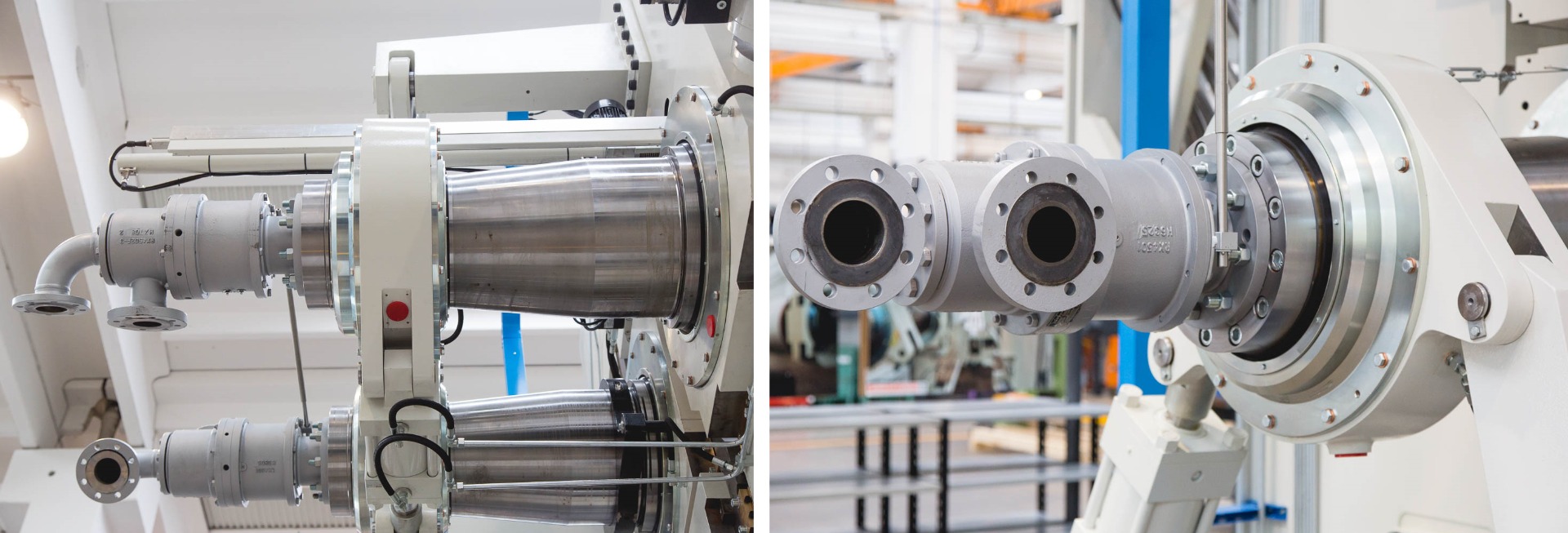

Rodolfo Comerio is the main company in Italy in terms of construction of calendering lines and systems for the lamination and embossing of thermoplastic foils and rubber.

Founded in 1878, today Rodolfo Comerio is a world-class company aware of the evolution of contemporary technological requirements. In recent years it has focused on the achievement of original process innovations intended to give its products special features, covered by international patents, and is proud to underline that 100% of its product is exclusively Made in Italy.

A WELL-ESTABLISHED PARTNERSHIP

Being known and appreciated all over the world means having achieved and having to maintain high standards of brand awareness and brand reputation; it is logical, therefore, that the company maintains tight control over the quality of the components used in its machines. This is why, when choosing rotary joints, the company focused on the offer of Johnson-Fluiten, which has always manufactured rotary joints for all segments of the mechanical engineering industry.

|

"Johnson-Fluiten is a well-known name in our industry, which we also frequently find in end customer specifications. Johnson-Fluiten rotary joints have now been adopted as standard in all our solutions because they are synonymous for guarantee and reliability". Nicola Fedele, Sales and Marketing Manager of Rodolfo Comerio |

|

A MULTI-FUNCTIONAL OFFER

The company's installations range from the processing of plastics such as PVC, PP, PE, TPO and TPU for the production of plastic film, multilayer film and reinforced multilayer film for flooring, to the production of rubberised fabric for tyres, conveyor belts and different rubber parts.

The wide range of solutions offered by Rodolfo Comerio is reflected in the need for components with diversified performance; handling multiple types of fluid such as diathermic oil (used for heating applications) and water (used for heating as well as cooling) can require very different performances from rotary joints in terms of speed, pressure and temperature.

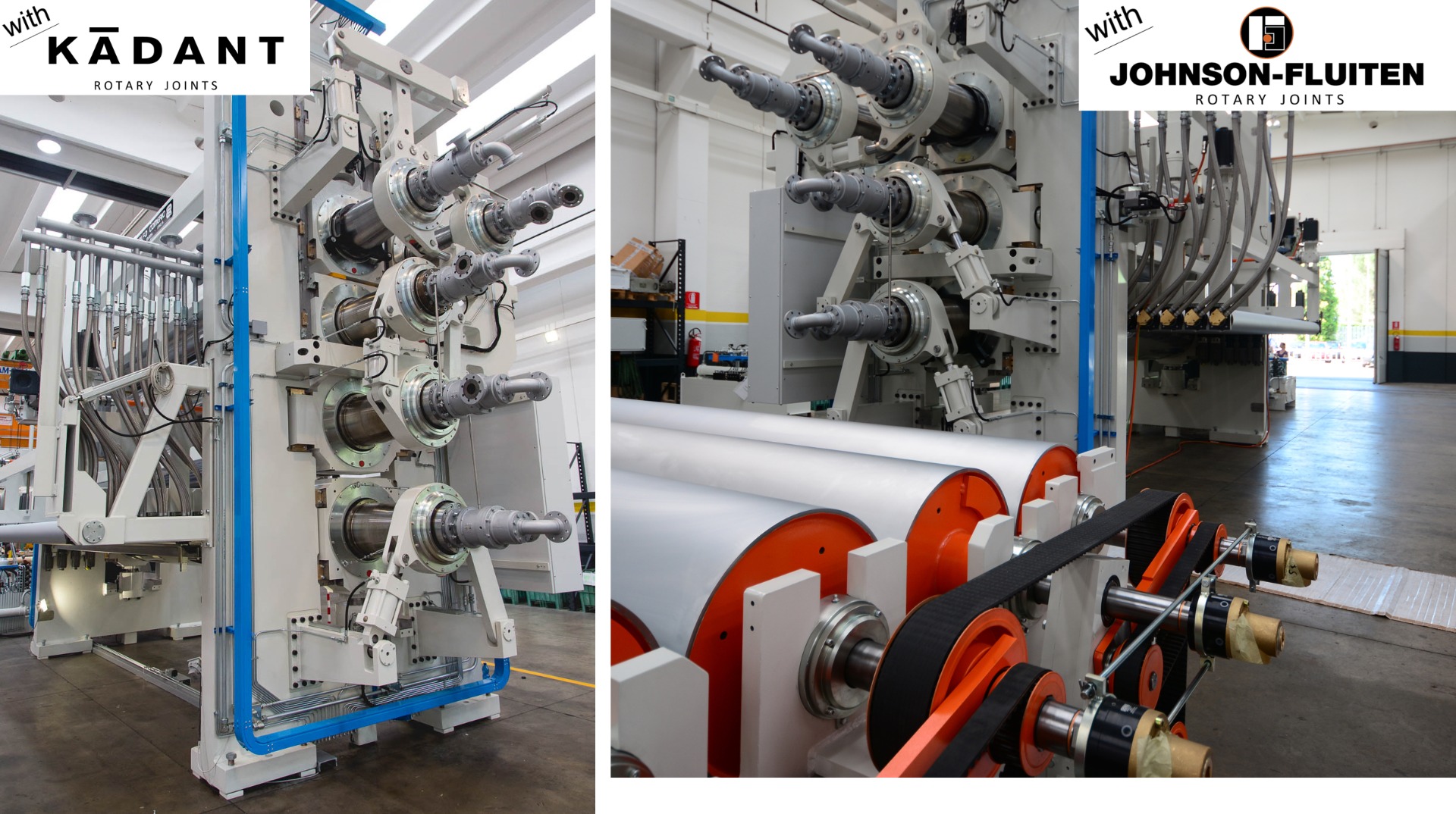

From this point of view, Johnson-Fluiten has proved to be an ideal partner: not only does the range of rotary joints in the catalogue include solutions for every need, but being part of the Kadant group, the versatility of the fluid handling solutions is such that the right product can always be found for every specific need. Rodolfo Comerio can easily use a relatively small number of references and find the ideal component for each system, simplifying stock management.

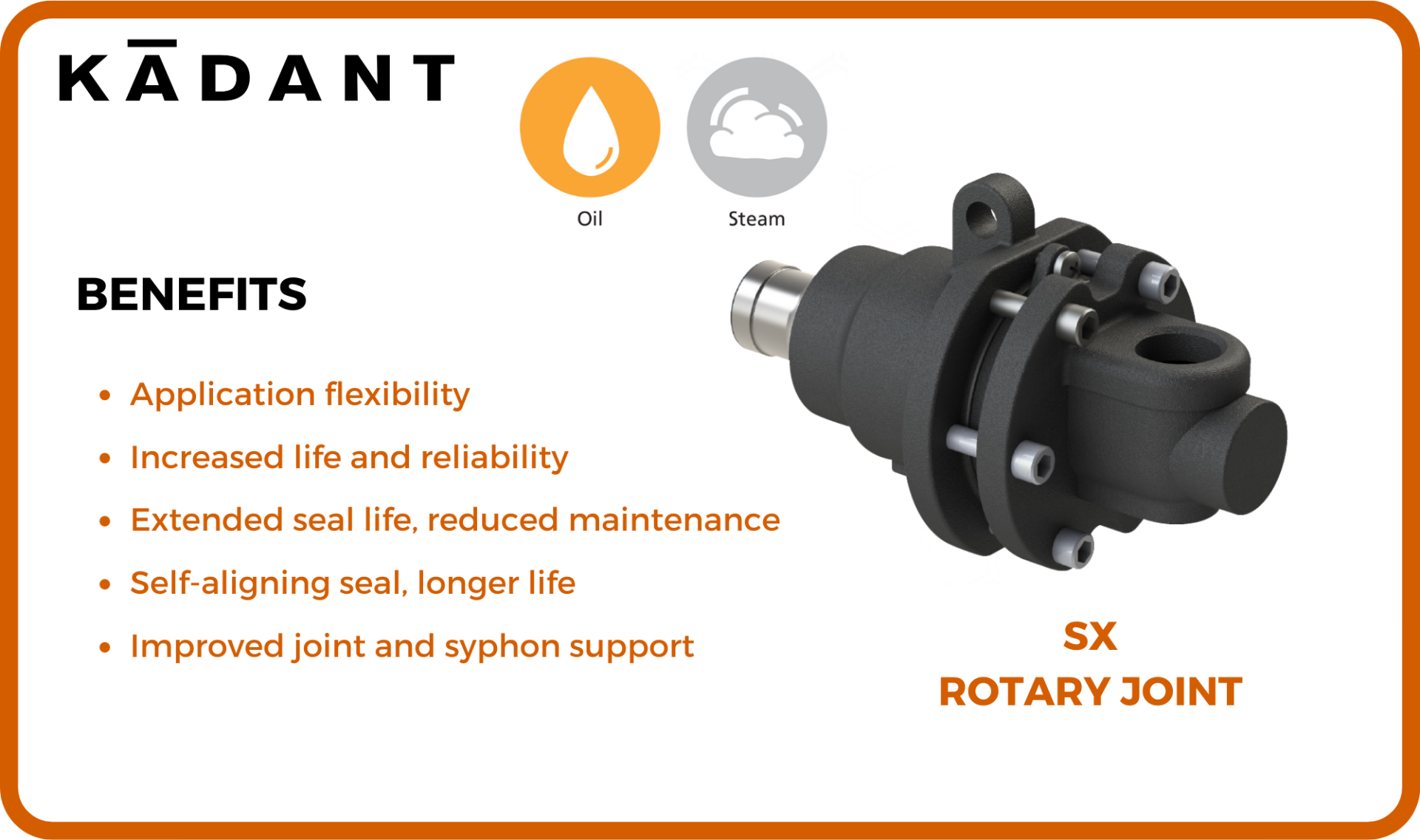

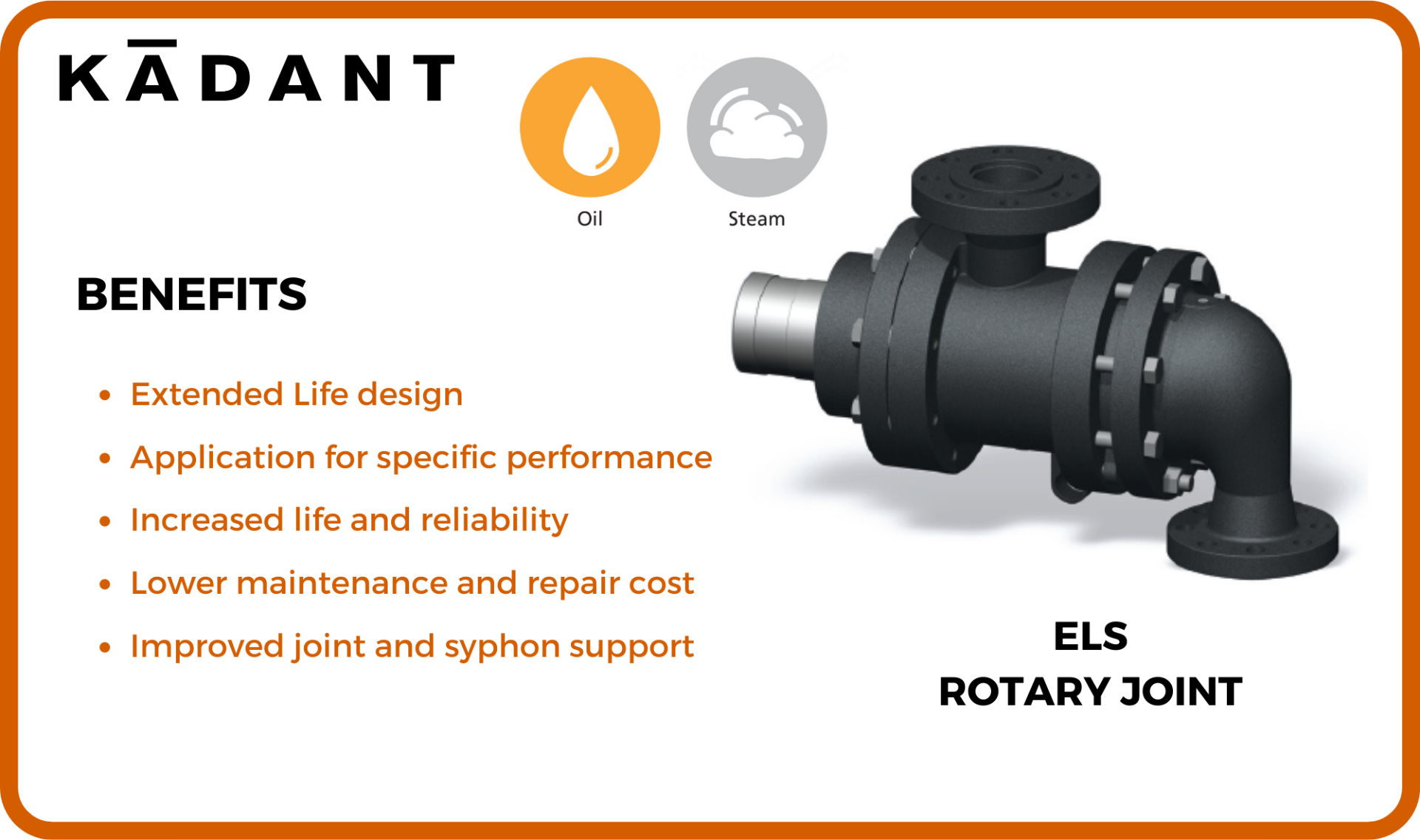

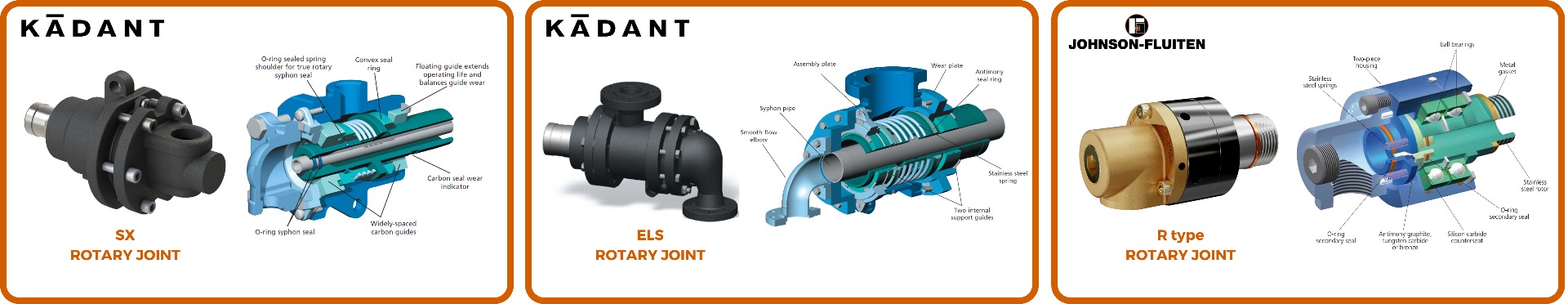

FOR EACH APPLICATION, A SOLUTION: DIATHERMIC OIL

Achieving maximum efficiency in fluid handling in plastics and rubber processing plants is only possible by using the right rotary joints; in this particular case, the products used for heating applications using diathermic oil are Kadant's SX-series rotary joints and ELS-series rotary joints

The SX rotary joint is equipped with two carbon-graphite guides that allow easy alignment and ensure long joint life even when installed on non-concentric cylinders. Thanks to its simple design, the SX rotary joint guarantees outstanding reliability as well as being perfectly adaptable to different types of oil and steam applications.

The ELS (Extended Life Series) rotary joint is an internally supported joint specially designed to solve the many wear problems encountered with conventional rotary joints in applications with high vibration. The joint is made with a double guide design; these two guides provide better internal support and allow the rotary joint to maintain proper alignment even when the roller or cylinder is not perfectly concentric. Thanks to its technology and design, this component guarantees longer life and reliability than standard products.

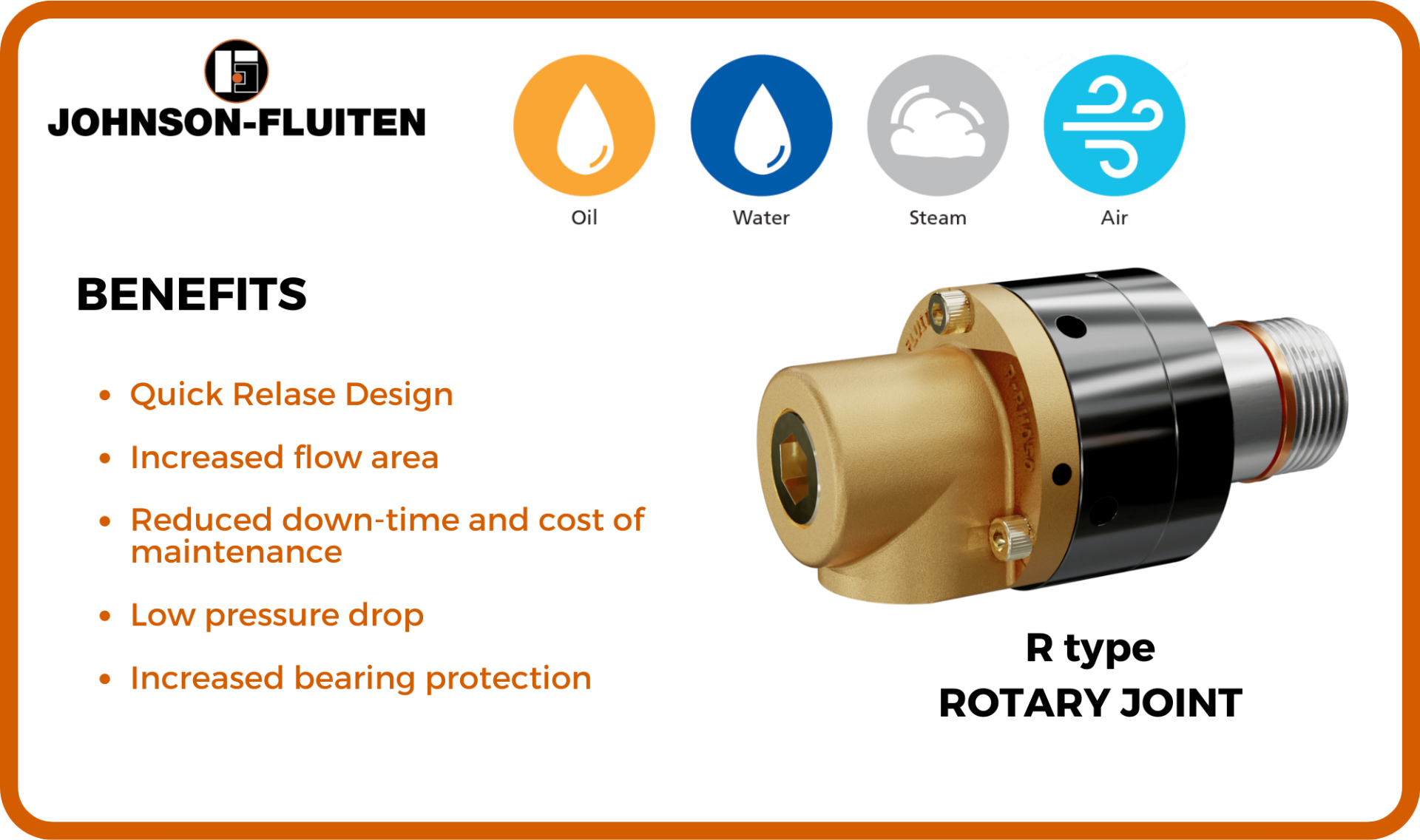

FOR EACH APPLICATION, A SOLUTION: WATER

In some applications, the handling of water at different temperatures (both hot and cold) is required, and it is in these cases that the R-series rotary joints manufactured by Johnson-Fluiten are the best solution.

The type R rotary joint is used to connect a stationary pipe to a rotating device. The fluid inside is sealed by a micro-lapped mechanical seal that guarantees total absence of leakage. The coupling is supported by two widely spaced ball bearings, but its unique feature is its quick-replacement design (QRD).

This component is designed to allow the joint to be handled while it is still installed on the machine, but this innovative technical solution also allows the rotary joint to be quickly adapted to fluids requiring different sealing materials should there be a different production need.

And for those machines with highly innovative characteristics, for which it is not always possible to have the joint with the required properties:

"Johnson-Fluiten is, in any case, able to provide quick assistance and to find new solutions suitable for our needs," says Fedele, who continues:

"We have been working with Johnson-Fluiten for many years now and they have always proven to be a reliable partner. We use a wide range of solutions, especially depending on the scope of the project.

ALL-ROUND SUPPORT

In addition to the reliability of the products, other features of Johnson-Fluiten's offerings have helped to consolidate the positive professional relationship with Rodolfo Comerio: from the complete commitment to provide free pre- and after-sales advice to the speed of delivery, everything contributes to making Johnson-Fluiten a highly valued partner.

"We are extremely satisfied with the cooperation with Johnson-Fluiten because of their reliability, the variety of products offered and the constant support." Nicola Fedele, Sales and Marketing Manager of Rodolfo Comerio |

|

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091