FAQ

WHAT ARE ROTARY JOINTS?

Rotary joints are essential sealing devices that connect rotating parts to fixed pipes, facilitating the transfer of various fluids such as steam, water, diathermic oil, coolant, hydraulic oil, and air.

Rotary unions can be designed with multiple passages to handle different types of fluids simultaneously.

These precision devices are essential for transferring fluids under pressure or vacuum between stationary and rotating parts. They provide a reliable seal between a stationary part (such as a pipe) and a rotating part (such as a roller, cylinder or spindle shaft), allowing fluids to flow in and/or out of the rotating part.

Rotary joints are designed to rotate around a specific axis and to contain and transfer fluids without leakage to the outside. The design can vary according to application specifications, adapting to high or low pressures, the number of revolutions and the number of independent passages required.

Rotary joints are widely used in many different industries, including in metal, textile, paper, food, chemical, petrochemical, automotive, pharmaceutical, construction equipment, floor and wall coatings, leather, wood, machine tools, mining, oil, plastics, printing, etc.

To summarise, rotary joints are crucial components in multiple industries, ensuring the sealing and efficient transfer of fluids between rotating and stationary parts in multiple application contexts.

If you want to know more, explore our contents:

OUR ROTARY JOINTS

WHAT DOES AN R/RH SERIES ROTARY JOINT MADE OF?

WHAT ARE THE TYPICAL APPLICATIONS OF ROTARY JOINTS?

Rotary joints are widely used in various applications where fluids need to be transported from stationary to rotating parts. The main operating conditions concern the heating and/or cooling of cylinders in industrial machinery in various sectors. Some of the main applications include

Energy Sector: Power generation in the wind and hydroelectric sector, involving heating, cooling and handling processes.

Paper and Paper Mills: Paper production in paper mills and corrugators in paper mills, involving heating and cooling processes.

Textiles: Coating and coating plants, leather processing machinery, and production of synthetic fibres such as meltblown and spunbond.

Rubber and Plastics: Cooling and heating calenders, extruders, rubber (tyre) production plants, PVC production, bubble wrap and laminates.

Chemical and Pharmaceutical: Processes for the production of active ingredients, machinery such as mixers, agitators, dryers and applications in cosmetics production processes.

Steel: Metal production, continuous casting and metal wire processing.

Food and Beverage: Food production and processing, cookers, sterilisers.

Machine Tools: Applications in CNC machines, drilling, milling, milling, electrospindles, transfer and rotary tables.

Printing: Applications in printing, converting and offset.

In a nutshell, rotary joints are essential in a wide range of industries, ensuring efficient transfer of fluids under the specific heating and cooling operating conditions required by various industrial processes.

Discover our rotary joint applications

Is your application not listed? We can provide a suitable product for your needs, contact our technical department for a free consultation:

- e-mail = info-jf@johnson-fluiten.com

- telefono = +39.023394091

WHAT ARE THE ADVANTAGES OF USING ROTARY JOINTS OVER OTHER SOLUTIONS?

Rotary joints offer significant advantages over other solutions when it comes to transferring liquids or gases to rotating parts without leakage. Some of the main benefits include:

1 - No Effective Alternatives: rotary joints are the primary solution when it is necessary to transfer fluids to rotating components. There are no equally effective alternatives to ensure continuity of flow without unwanted leaks.

2 - Reliability and Durability: Compared to other solutions that may employ seals and packings, rotary joints are considerably more reliable and durable. Seals and packings can wear out faster, compromising system integrity over the long term.

3 - Minimising Leakage: Rotary joints are precisely designed to ensure a tight seal between rotating and stationary parts, minimising fluid leakage. This is especially critical in applications where precision fluid handling is essential.

4 - Adaptability to Different Applications: The versatility of rotary joints makes them suitable for a wide range of industries and applications. They can be custom-designed to meet specific needs, adapting to different operating conditions and fluids.

5 - Less Maintenance: Because rotary joints are designed to be more durable and reliable over time, they generally require less maintenance than other solutions that may need frequent replacement of seals or packings.

6 - Operational Efficiency: With their ability to handle fluids efficiently and reliably, rotary joints help maintain the operational efficiency of systems, reducing downtime and increasing overall productivity.

In summary, the use of rotary joints is an unsurpassed choice when it comes to transferring liquids or gases to rotating parts, offering reliability, durability and a level of precision that is difficult to achieve with other seal and packing based solutions.

Discover all our solutions

WHAT MATERIALS ARE USED IN THE PRODUCTION OF JOHNSON-FLUITEN ROTARY JOINTS?

Johnson-Fluiten rotary joints are manufactured from a careful selection of high-quality materials to ensure superior performance and durability.

Some of the main materials used include:

Steel: Steel is often used for strength and mechanical resistance. Its presence helps ensure the structural stability of Johnson-Fluiten rotary joints.

Anodised Aluminium: Anodised aluminium offers lightness, making it useful in situations where it is crucial to keep the overall weight of the system low.

Stainless Steel: Stainless steel is valuable for its corrosion resistance, making it suitable for environments involving aggressive liquids or gases.

Hastelloy: This material offers high chemical resistance, making it ideal for corrosive environments. Rotary joints with Hastelloy parts are used in contexts that require robust resistance to chemical corrosion.

Tungsten Carbide and Silicon Carbide and Graphite: The correct coupling of these materials allows the joint to work with various fluids (even liquids with abrasive parts) and allows the joint to run dry.

Kalrez: This elastomer is chosen for its performance at extremely high temperatures. In rotary joints, Kalrez can be used where high performance in terms of high temperature resistance is required.

The use of this variety of materials allows Johnson-Fluiten rotary joints to adapt to different operational requirements, while providing chemical, thermal and mechanical resistance for optimal performance in a variety of industries.

Discover the Quality of Our Materials: Request Detailed Information

Request a Materials Assessment for Your Specific Needs

WHAT DIMENSIONS ARE AVAILABLE FOR ROTARY JOINTS?

Johnson-Fluiten rotary joints offer an extensive range of sizes to meet different application needs, providing flexibility and adaptability to a wide range of industrial systems.

The dimensions of our couplings cover a range from 1/4" to 14", thus offering a tailor-made solution for multiple applications.

See all our solutions

HOW IS THE INSTALLATION OF ROTARY JOINTS CARRIED OUT?

The installation of rotary joints is a critical process that requires care and precision to ensure the proper functioning of the system.

Installation steps may vary depending on the specific type of rotary joint in use. For detailed guidance, it is essential to refer to the dedicated installation manual supplied with each type of Johnson-Fluiten rotary joint.

For specific installation information on Johnson-Fluiten products, please refer to the individual product pages on the website.

For further details and specific instructions, please refer to the resources provided on the JOHNSON-FLUITEN product pages:

WHAT IS THE AVERAGE LIFETIME OF JOHNSON-FLUITEN ROTARY JOINTS?

The lifetime of Johnson-Fluiten rotary joints can vary depending on a number of factors, mainly related to the type of application, the correct installation and the operating conditions of the fluid handled.

Our focus on design and build quality has enabled us to achieve extraordinary results, with cases where our rotary joints have performed flawlessly without requiring maintenance for over 20 years.

Factors influencing durability include:

Type of application: the life of rotary joints is closely linked to the specific context of use. More demanding applications or special requirements can influence the overall life of the rotary joint.

Correct installation: Careful installation is essential to ensure the optimal service life of the rotary joint. Carefully following the instructions given in the installation manual is crucial to avoid future problems.

Operating conditions: the characteristics of the fluid handled are decisive. Aggressive substances, extreme temperatures or high pressures can affect the service life of the rotary joint. Our range of high-quality materials helps to mitigate these effects.

Design and Build Quality: The advanced design and build quality of Johnson-Fluiten rotary joints are distinctive. Attention to detail and the use of durable materials result in excellent performance over time. Cases where our rotary joints have operated maintenance-free for more than 20 years testify to our commitment to reliable and durable products.

Our tips for maximising rotary joint life:

Preventive Maintenance: We recommend regular preventive maintenance programmes to preserve the optimal performance of rotary joints over time.

Constant monitoring: Keeping an eye on operating conditions and acting promptly in the event of changes or anomalies can help extend the life of your rotary joint.

For more information on the lifetime of our rotary joints and to find out which solution best suits your needs, please visit the Johnson-Fluiten product pages.

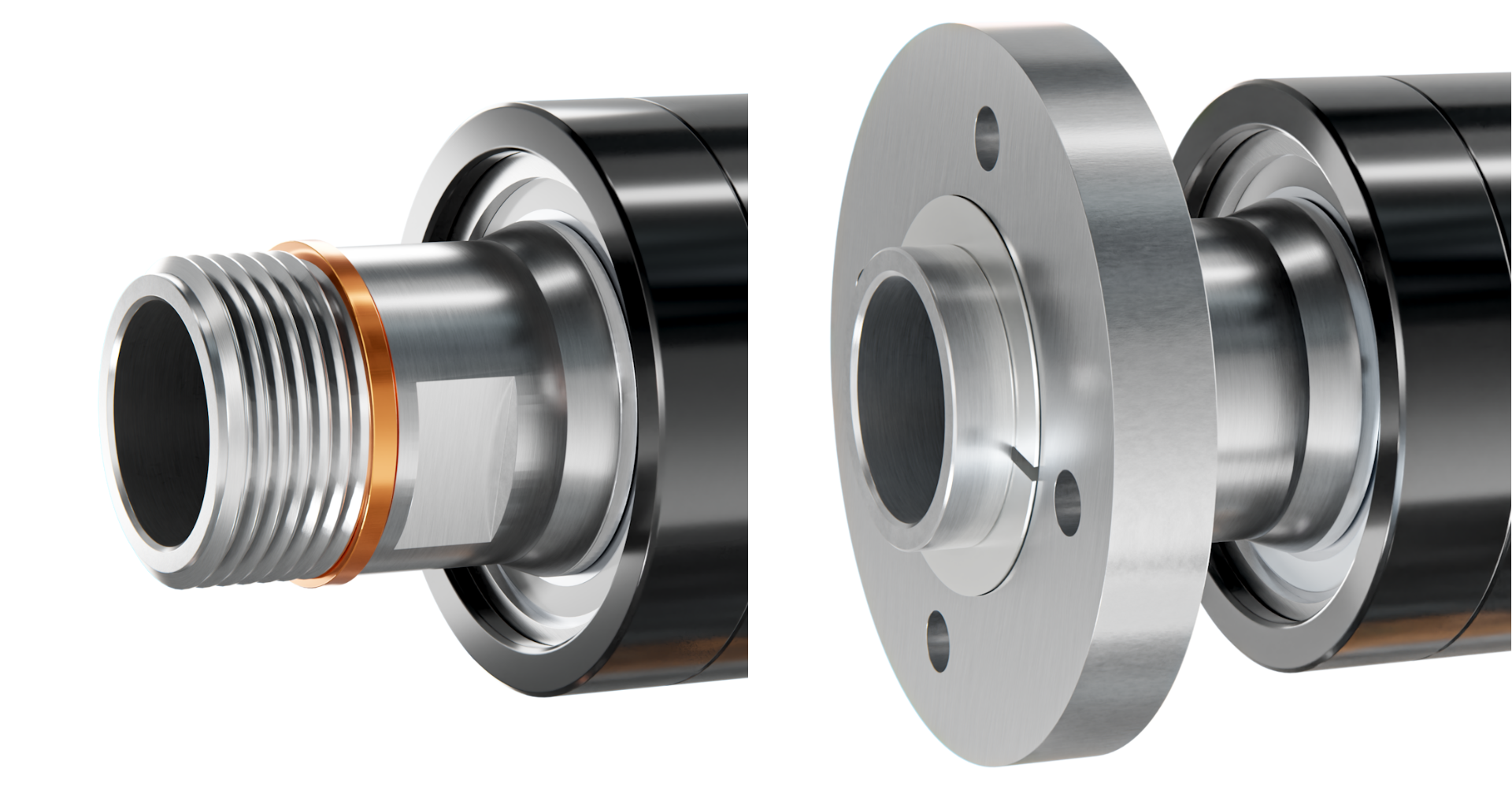

WHAT TYPES OF CONNECTIONS ARE AVAILABLE FOR ROTARY JOINTS?

Johnson-Fluiten rotary joints offer a variety of connection options to suit different application needs.

The main types of connections available include:

Thread Connection:

GAS Thread: Suitable for standard GAS threads, this option offers a robust and reliable connection, often used in multiple industries.

NPT (National Pipe Thread): Conforming to the NPT standard, this type of thread is widely used in hydraulic and pneumatic systems, offering a hermetic connection.

Metric Thread: Designed to metric standards, the metric thread connection is ideal for applications requiring precise and uniform measurement.

Flange connection:

DIN (Deutsches Institut für Normung) Flanges: DIN flanges conform to German standards and are commonly used in industrial applications throughout Europe, offering a robust connection.

ANSI (American National Standards Institute) Flanges: ANSI flanges conform to US standards and are often used in industries that follow US regulations, ensuring compatibility and reliability.

ASME (American Society of Mechanical Engineers) flanges: These flanges comply with ASME standards, widely adopted in industry to ensure uniformity and safety in connections.

For all sizes and availability of the different attachment types, we invite users to contact our customer service department.

Our team is ready to provide personalised assistance, ensuring that users find the ideal solution for their specific application needs.

Note: The wide range of available couplings may be subject to modification and customisation according to specific requirements. Please contact our customer service department for detailed, customised information.

WHAT KIND OF BEARINGS CAN BE MOUNTED ON ROTARY JOINTS?

Johnson-Fluiten rotary joints are designed for optimum performance, and the choice of bearing type plays a crucial role in their efficiency and reliability.

Available bearing options include:

1- Ball Bearings: Ball bearings are widely used to ensure smooth motion and reduced friction. They are ideal for applications requiring smooth rotation and good radial load capacity.

2- Roller Bearings: Roller bearings are designed to handle heavier radial loads and are suitable for applications where uniform load distribution is essential. They are particularly effective in variable load situations.

3- Backlash C3 or C4 (for high temperatures): The C3 or C4 internal clearance is a characteristic that influences the tolerance of the bearing. For high temperature applications, the use of bearings with C3 or C4 clearance helps to manage thermal expansion and maintain optimum performance.

4- Stainless Steel Bearings: Stainless steel bearings are used in corrosive environments or in the presence of aggressive liquids. These bearings offer corrosion resistance, helping to extend the life of the rotary joint.

5- Ceramic bearings (for high speeds): Ceramic bearings are chosen for their wear and temperature resistance properties. They are particularly suitable for high-speed applications, helping to reduce friction and extend the life of the rotary joint.

6- Angular Contact Bearings (resistance to loads): Angular contact bearings are designed to withstand combined radial and axial loads. This characteristic makes them suitable for situations where different stresses are present.

The choice of bearing type depends on the specific requirements of the application. Johnson-Fluiten offers the option of customising the bearing configuration to suit each customer's unique operating conditions.

For further details on available bearing options and for personalised advice, please contact our customer service department.

We are ready to provide detailed information and assistance to ensure the optimal choice of bearings for your rotary joints.

CAN FIXED HOSES BE USED TO CONNECT ROTARY JOINTS?

Absolutely not, the use of fixed hoses to connect rotary joints is not permitted.

It is essential to always opt for the use of flexible hoses to ensure proper system operation. The use of rigid hoses can cause significant problems that affect the overall performance of the rotary joint.

The following are some reasons to avoid the use of rigid hoses:

1- Limited Flexibility:

The lack of flexibility in rigid pipes can hinder rotary movement, causing excessive mechanical stress on the connection and rotary joint components.

2- Risk of Leaks and Failures:

The lack of flexibility and adaptability of rigid pipes increases the risk of leaks, premature failure and deterioration of rotary joint performance over time.

For more information on the importance of using flexible hoses with rotary joints, please read our article on optimal piping in our blog.

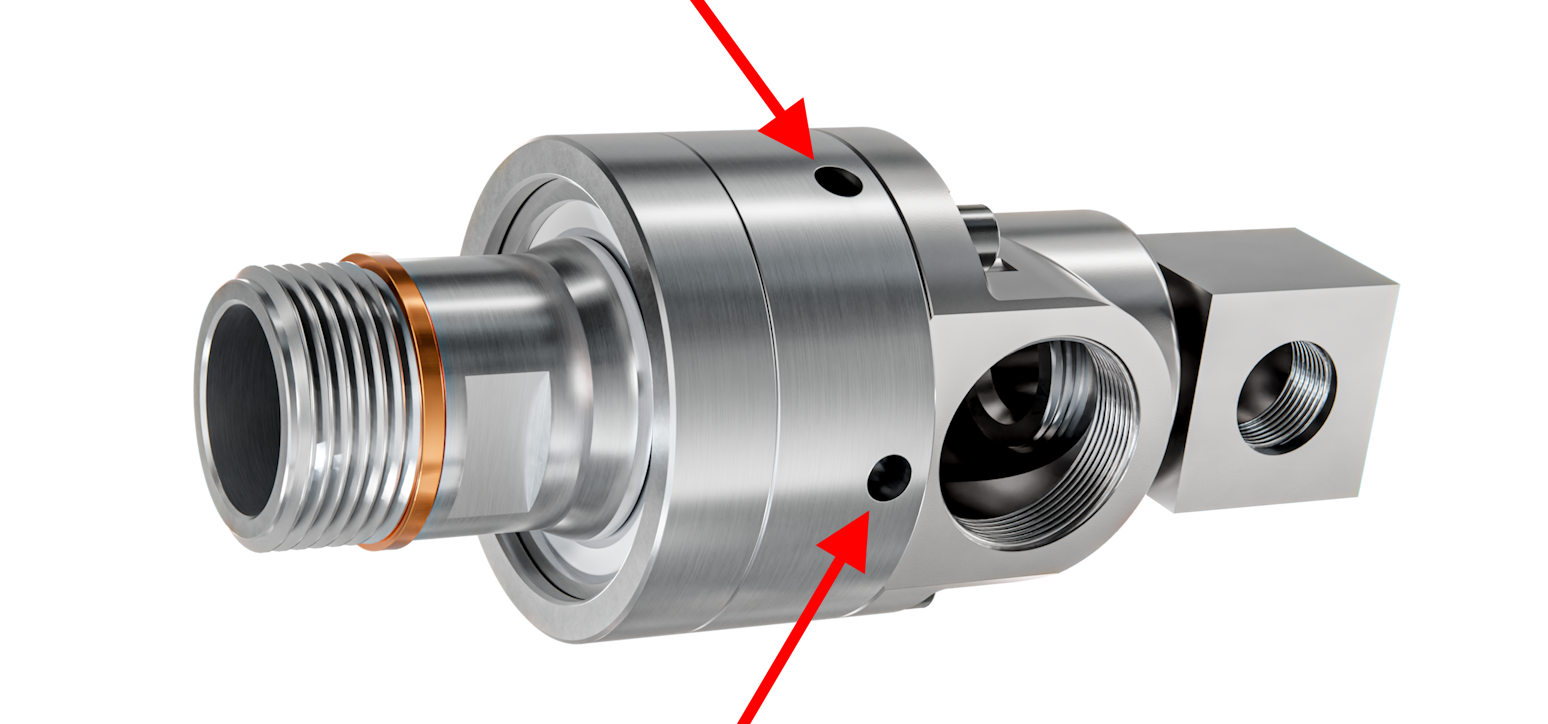

WHAT ARE THE HOLES ON THE ROTARY JOINT BODY FOR?

The holes in the body of the rotary joint play a key role in ensuring the proper functioning and preventive maintenance of the device.

They are specifically designed as drainage holes, with the following main functions:

Fluid Drainage:

The holes on the body of the rotary joint act as drainage channels, allowing the elimination of any fluids that might accumulate due to physiological leaks or minor variations during normal operation.

Monitoring the condition of the component:

In case the mechanical seal of the rotary joint needs maintenance or replacement, significant fluid leakage through these holes can act as an alarm signal. This feature allows early identification of the need for corrective action, helping to avoid sudden failures or excessive leakage.

IS IT POSSIBLE TO REPAIR A JOHNSON-FLUITEN ROTARY JOINT?

Yes, it is absolutely possible to repair a Johnson-Fluiten rotary joint.

At our manufacturing facility in Pero (MI), we offer a complete repair and maintenance service for our rotary joints, ensuring maximum efficiency and durability.

We perform rapid replacement of the mechanical seal, bearings and worn parts ensuring effective fluid sealing and restoring optimal performance of the rotary joint.

For our customers, we offer the option of purchasing spare parts directly from JOHNSON-FLUITEN S.r.l. This option allows customers to proceed with maintenance themselves, reducing downtime and streamlining the rotary joint management process.

For more details on Johnson-Fluiten rotary joint repair services or to request a service, please contact our customer service department.

We are here to ensure maximum efficiency and reliability of your rotary joints.

HOW DO I MANAGE THE MAINTENANCE OF ROTARY JOINTS?

Effective maintenance management of rotary joints is essential to ensure optimal performance and prolong their service life. Following these steps simplifies the process:

1 - Periodic Monitoring:

Conduct regular monitoring to identify signs of leakage or malfunction. Visually inspect rotary joints and pay attention to any changes in performance.

2 - Reporting Leaks:

If fluid leaks from the rotary joint, contact Johnson-Fluiten personnel immediately to report the problem. Early identification and resolution of defects is crucial to avoid greater damage.

3 - Johnson-Fluiten All-Inclusive Intervention:

Johnson-Fluiten offers an all-inclusive intervention service that includes diagnosis, repair, and replacement of damaged components. Our qualified staff can handle the entire process, ensuring quick and efficient restoration of the rotary joint. With our experience and professionalism, we ensure accurate and timely interventions to restore the optimal performance of rotary joints. The rapid intervention of skilled personnel helps minimize downtime, maintaining the productivity of your system.

As an alternative to full service, Johnson-Fluiten personnel can recommend the appropriate kit for replacing the mechanical seal. In this case, detailed assembly and disassembly instructions are provided to enable users to handle the maintenance themselves. Intervention that, only on our rotary joints, can be carried out the few minutes.

For efficient maintenance management of rotary joints, please contact our customer service team. We are here to offer tailored solutions and ensure the proper functioning of your devices.

HOW DO I CHANGE WEARED MECHANICAL SEAL IN A ROTARY JOINT?

Replacing the worn mechanical seal of a rotary joint can be an efficient and quick operation by following the dedicated instructions for each type of rotary joint.

In particular, our R-RH joints are designed with QRD technology, which simplifies the replacement process without having to remove the component from the machine.

Access the web page devoted to rotary joint instructions and catalogs on our website.

You will find detailed instructions for replacing the mechanical seal specific to your rotary joint model.

Should you have any doubts or encounter difficulties during the process, our customer service team is available to provide support.

You can contact us by phone or email to get immediate answers to your questions.

WHERE CAN I FIND INSTRUCTIONS FOR ASSEMBLY OR DISASSEMBLY OF THE ROTARY JOINT?

Instructions for assembly and disassembly of our standard rotary joints are available:

1) on the individual product pages (you can search by catalog or by code in the search box at the top right)

2) at the following link you will find all the files in pdf format grouped by type

Should you not find the content he you are looking for, you can contact our customer care department:

- via email = info-jf@johnson-fluiten.com

- by phone = +39.023394091

HOW CAN I FIND THE RIGHT ROTARY JOINT FOR MY NEEDS?

There are 6 important variables in selecting a rotary joint: pressure, speed (rpm), temperature, fluid, volume, and number of passes.

1- Pressure: fluid pressure affects the seal and/or bearings of the rotary joint. Higher pressure will limit the number of joints that can be used.

2 - Speed: Rotational speed affects bearings and sealing. Seals seal the fluid between the rotating part of the machine and the stationary part. They are subject to friction and are wear parts.

3 - Temperature: temperature affects many parts of the rotary joint: seals, bearings and choice of materials. The mechanical seal often reaches 340°C, for o-rings and lip seals the temperature is determined by the limits of the material of which they are composed. The temperature is influenced by the temperature of the fluid and additional friction in the mechanical seal and bearings.

4 - Fluid: the fluid affects the seal. Some sealing materials do well with water while others with oil or air. Small amounts of fluid will leak between the rotating and stationary parts: depending on the choice the fluid will lubricate the seal and improve performance, in other applications in this case the seal will perform worse.

5 - Volume: determines the size of the passages and thus the size of the joint to be used. Important is to consider the velocity of the fluid within the passage.

6 - Number of passages: determines the joint configuration. Rotary joints often have 1 or 2 passages and have a wide range of sealing materials available. When 3 or more passages are needed, lip seals and o-rings are used.

Contact our sales department for immediate support!

WHAT IS YOUR WARRANTY POLICY?

Our warranty policy reflects our commitment to quality and customer satisfaction. Here are the main details of our warranty policy which can be found in full at this link:

Warranty Duration:

All of our products are covered by a 12-month warranty from the date of invoice. This warranty offers protection against any defects and/or manufacturing defects that may arise during this period.

Interventions Covered by Warranty:

In the event that a product has defects or faults covered by the warranty during the warranty period, we guarantee repair or replacement of the defective product. This coverage applies only during the warranty period.

Applications Consistent with Declared Specifications:

The warranty applies only to products used in environments and for applications consistent with the vendor's stated specifications. Misuse of the product is prohibited and is not covered under the warranty.

Warranty Limitations:

Warranty coverage is limited to the cost of repair of defects and/or faults or replacement of the defective product. In no case will the Company's liability exceed the original price paid by the customer for the product.

Warranty Exclusions:

The warranty will not be valid if the inconvenience or defect is caused by improper or inappropriate application to the product. In addition, if the product is modified or parts are replaced without the seller's authorization, this will void the warranty

Normal Wear:

The warranty does not cover normal wear parts. This is important to consider to ensure realistic management of expectations for component life.

Reference Warranty Certificate:

For further details and specifications, we encourage customers to refer to the "Certificate of Warranty" document. This document provides detailed information on the specific terms and conditions of the warranty.

Our warranty policy aims to provide customers with peace of mind by ensuring that our products undergo rigorous testing and are supported should any problems covered by the warranty occur. Read the full content here:

https://johnson-fluiten.com/en/warranty

For further details or questions, we are available through our customer service department.

HOW CAN I CONTACT YOU FOR FURTHER QUESTIONS OR SUPPORT?

We are always ready to assist you and answer all your questions. Here are the most effective ways to contact us:

Phone:

You can contact us directly by calling our dedicated phone number: +39.023394091. Our customer service team is available to take your calls and provide immediate assistance.

Email:

For questions, support requests or additional information, please email info-jf@johnson-fluiten.com. Our support team responds promptly to emails to ensure that you receive all the information you need.

Website Contact Form:

Visit our website and use the contact form available in the "Contact Us" section. Fill out the form with your questions or requests, and our team will respond as quickly as possible.

Physical Location:

If you prefer direct contact, you can visit our physical location. You can find location details on our website. However, we recommend that you schedule a visit in advance to ensure that we are ready to welcome you in the best way possible.

Your satisfaction is our priority, and we are here to provide the support you need. Choose your preferred method of contact and contact us with any questions or needs. We look forward to hearing from you and providing you with excellent service.

HOW CAN I PURCHASE A JOHNSON-FLUITEN ROTARY JOINT IF I AM OUTSIDE ITALY?

Buying a Johnson-Fluiten rotary joint from abroad is easy thanks to our global network.

We rely on KADANT's strong sales and distribution network to meet the needs of international customers. We cover all continents and most foreign countries through this partnership.

For detailed information on the availability of our products in your country and for purchasing support, please contact our customer service department. They will be able to provide specific information on geographic coverage and direct you to the KADANT distributor or representative nearest you.

We are committed to making the purchasing experience of our international customers easy and efficient.

Contact us for personalized assistance to ensure you get the perfect Johnson-Fluiten rotary joint for your needs, wherever you are in the world.

WHAT IS THE DELIVERY TIME FOR A STANDARD JOHNSON-FLUITEN ROTARYJOINT?

For standard joints in our catalog, we guarantee quick delivery within 24 hours from the time we receive the order (within the Italian territory).

We pride ourselves on offering prompt and efficient service to ensure that our customers can receive their products in the shortest possible time.

We are committed to maintaining high standards of prompt delivery.

WHICH FORWARDER DO YOU USE TO SHIP THE PRODUCTS?

Currently, our main couriers are GLS and DHL, two of the leading international shipping services. These partnerships enable us to offer fast, traceable and secure shipments.

Upon customer request, we offer the option of using our own courier to pick up products directly from our warehouse.

This option is designed to provide maximum flexibility and adapt to our customers' specific needs.

We are committed to providing flexible and reliable shipping options to ensure that our customers receive products in a safe and timely manner.

IS IT POSSIBLE TO BUY SPARE PARTS FOR ROTARY JOINTS?

Yes, we offer a full range of options for purchasing replacement parts for Johnson-Fluiten and Kadant Johnson rotary joints, providing maximum flexibility for our customers.

On our website, we provide complete replacement kits for our rotary joints.

These kits contain all the essential parts needed for maintenance and replacement, simplifying the purchasing process.

In addition to complete kits, we offer the option of purchasing individual parts for rotary joints separately. This allows customers to select exactly the replacement parts they need, optimizing costs and reducing waste.

Individual parts available for purchase separately includerotors, bodies, housings, seals, bearings and seal rings. This wide range of options makes it possible to meet specific replacement or improvement needs.

Our customer service department is available to provide support in selecting parts. If customers have specific questions or need assistance in selecting the correct parts, we are ready to help.

WHERE CAN I FIND PRICES AND AVAILABILITY?

Prices and availability of our products are not made public to ensure personalized handling of our customers' requests. However, we do provide easy access to get instant quotes and availability information.

On our website, you can request an instant quote by filling out a simple online form. This option allows customers to enter their desired product specifications and quickly receive a customized quote.

Our customer service team is available to provide personalized assistance and answer any questions you may have.

IS IT POSSIBLE TO REPLACE A ROTARY JOINT FROM ANOTHER BRAND WITH A JOHNSON-FLUITEN PRODUCT?

Certainly, at Johnson-Fluiten we specialize in offering customized and compatible solutions for our customers' specific needs.

If you have the rotary joint code for another brand, you can send it to us, along with the operating conditions under which it is to work, through our website or by contacting our customer service department. This code will help us understand the technical specifications and dimensions of the joint to be replaced.

Our dedicated experts will review the provided code and recommend the most suitable Johnson-Fluiten product as a replacement. We guarantee an accurate match to ensure trouble-free installation and optimal performance.

Our compatibility guarantee ensures that the recommended Johnson-Fluiten rotary joint meets or exceeds the technical specifications of the joint to be replaced. We are committed to providing reliable, high-quality solutions.

Replacing a rotary joint from another brand with a Johnson-Fluiten product is an effective way to improve system performance and durability. To receive a customized proposal, please send us the part number of your existing joint through our website or contact our customer service department directly.

We are here to offer solutions tailored to your specific needs.

IS IT POSSIBLE TO PURCHASE THE INTERNAL SIPHON FOR DOUBLE-PASS ROTARY JOINTS?

Certainly, at Johnson-Fluiten we are dedicated to providing a full range of solutions for our customers' needs, including add-ons such as the internal syphon for double-pass rotary joints.

Our customer service team is ready to help and provide detailed information on the availability, cost and options available for the internal syphon.

We are here to simplify the procurement process to meet your needs.

IS IT POSSIBLE TO HAVE CUSTOM OR COMPLETELY CUSTOM ROTARY JOINTS FOR SPECIAL NEEDS?

Absolutely, at Johnson-Fluiten we specialize in designing and manufacturing customized or fully custom rotary joints to meet the particular needs of each customer.

Johnson-Fluiten has a dedicated in-house R&D and technical department. This facility allows us to thoroughly understand our customers' specific needs and develop custom solutions to suit each application.

With Fluten's input and long experience in mechanical seals, Johnson-Fluiten is positioned as a benchmark in the custom rotary joint industry. This expertise allows us to tackle unique challenges and design custom rotary joints with high performance.

We work closely with our clients to fully understand their specific needs, offering technical advice and design suggestions. This collaboration enables us to provide custom solutions that exceed expectations. When necessary, we develop prototypes to test and validate the proposed custom solution. This ensures that the custom rotary joint fully meets the required performance.

We offer complete support from the design phase to manufacturing and installation. Our goal is to ensure that the custom rotary joint works flawlessly in your specific application.

Put us to the test! Call our department now to get your solution now

IS IT POSSIBLE TO RUN AIR AND LIQUID IN THE SAME ROTARY JOINT?

Our mechanical seals are designed with high-quality materials that ensure flawless sealing for a wide range of fluids, including air, water, oil, and others.

In some rotary joint lines, continuous 24/24 dry operation is possible without compromising performance.

We also offer rotary joints designed with multiple passages, allowing simultaneous transfer of several fluids in separate passages. This feature is ideal for applications that require handling multiple types of fluids simultaneously, without risk of cross-contamination.

Our team of experts is available to provide customized technical advice and guide customers in selecting the best solution for their specific needs.

Whether for complex industrial applications or unique requirements, Johnson-Fluiten rotary joints are designed to exceed expectations.

For more information on how to implement air and fluid circulation in our rotary joints, contact our dedicated customer service team. We are here to offer solutions tailored to your specific needs.

IS IT POSSIBLE TO APPLY AN AXIAL AND/OR RADIAL LOAD ON A ROTARY JOINT

As a rule, the application of axial and radial loads on rotary joints should be avoided, as such loads can impair the performance of the component.

Especially the application of radial loads can lead to premature wear or malfunction.

To obtain specific information on allowable loads for a particular rotary joint or to receive customized advice, please contact our customer service department.

WHAT CERTIFICATIONS ARE AVAILABLE FOR JOHNSON-FLUITEN ROTARY JOINTS?

Johnson-Fluiten rotary joints conform to rigorous quality and safety standards, supported by various certifications that attest to compliance with the specific requirements of different industries.

Here is a list of the main certifications available for our rotary joints:

ATEX certification:

Our rotary joints can be supplied with ATEX certification, ensuring compliance with European safety regulations for use in potentially explosive atmospheres. This certification is particularly relevant for sectors such as the chemical and pharmaceutical industries and in the presence of hazardous fluids.

FDA certification:

Rotary joints intended for sectors such as the food and pharmaceutical industries can be provided with FDA certification. This certification attests to compliance with the hygiene and safety standards set by the Food and Drug Administration.

Certification of Testing:

Each Johnson-Fluiten rotary joint undergoes rigorous testing during production. The testing certification attests that the joint has successfully passed all required quality and functionality tests.

Materials Certificate:

We provide a certificate of the materials used in the production of rotary joints. This document details the composition and specifications of the materials used, ensuring transparency about the quality of the components.

Certificate of Conformity:

Each rotary joint is accompanied by a Certificate of Conformity, attesting that the product meets the specifications required by the customer and applicable industry regulations.

Certificate of Provenance:

The Certificate of Provenance confirms the origin of the product, providing reassurance about the traceability and authenticity of the rotary joint.

For more details on specific certifications for a particular rotary joint or industry, please contact our customer service department. We are committed to providing reliable and certified solutions for your needs.

IS IT POSSIBLE TO USE A DRY ROTARY JOINT (WITHOUT FLUID)?

Johnson-Fluiten rotary joints feature materials and technologies that allow dry operation without compromising performance.

The rotary unions can be used dry, with pressurized air, ensuring reliable operation even in the absence of specific fluids such as oil or water.

This option is useful in applications where compressed air is already available in the system.

The dry operation option offers flexibility in design and application choices.

Rotary couplings can be used in a variety of industries and applications, tailoring them to specific customer needs.

Find the solution that's right for you!

WHAT FILTRATION IS NECESSARY TO HAVE?

The type of filtration required for your rotary joint depends on the specific requirements of the application and context in which the joint is used and also of the industry and application.

For example, in the machine tool industry, 50-micron filtration may be required to ensure proper operation of the joint and durability of its components.

Johnson-Fluiten offers customized solutions to suit the customer's filtering needs.

For example, for environments with abrasive particles in suspension, we can offer couplings with tungsten carbide seal rings, which are known for their resistance to wear and abrasive conditions.

Want to spaerne more? Contact one of our experts for all the details

WHAT CAUSES A ROTARY JOINT TO FAIL?

Failures of a rotary joint can be caused by several reasons, and it is critical to understand them to ensure proper operation and durability of the component.

Here are some common causes:

1 - Improper Installation:

Improper installation can lead to operational problems. It is essential to carefully follow the installation instructions supplied with the rotary joint. If necessary, consult the manual dedicated to the specific type of joint.

2 - Wear of Internal Parts:

Over time, the internal parts of the joint may wear out due to normal operation. Prolonged use without preventive maintenance can accelerate wear, leading to premature failure.

3 - Improper Use:

Using the coupling beyond the operating conditions for which it was designed can cause failure. It is important to comply with the usage specifications and not to exceed the operating limits of the joint.

4 - Excessive Vibration:

Intense vibration can adversely affect the life of the joint. When possible, reduce application vibration or install anti-vibration devices to protect the joint.

5 - Loads:

The application of radial and axial loads.

Remember that regular maintenance and proper handling of the application can greatly reduce the risk of premature failure. If you have any problems or questions, our customer service team is available to offer specific assistance and advice.

HOW CAN I RECOGNIZE AND CORRECT ABNORMAL VIBRATION IN THE ROTARY JOINT?

Recognizing and correcting abnormal vibrations in the rotary joint is crucial to ensure reliable operation and prolong component life.

A dial indicator should be used to detect any deviations in the rotation of the joint. This allows early identification of concentricity problems or imbalances.

Next one must ensure that the rotary joint is properly centered on the rotating shaft. Deviations from centering can cause unwanted vibrations.Measure the centering and make corrections if necessary.

It should be verified that the seat of the joint is in accordance with specifications.

Irregularities in the mounting surface can cause vibration. If necessary, rectify or replace the seat.

WHAT TO DO IN CASE OF EXTERNAL DAMAGE TO THE ROTARY JOINT BODY?

If there is external damage to the rotary joint body, it is important to approach the situation with caution.

Here is what to do in case of minor damage:

1- Make a visual assessment of the external damage. If it is superficial or light damage, it will generally not affect the performance of the joint. If you have any doubts or concerns about the safety and performance of the joint, you can contact the technical service department for personalized advice.

2- Continue to monitor the performance of the joint over time. If you notice significant changes in operation or any leaks, it is essential to take immediate action.

WHAT ARE THE RECOMMENDED EMERGENCY PROCEDURES IN THE EVENT OF A CRITICAL ROTARY JOINT FAILURE?

In the event of a critical failure involving leakage or major malfunction, the first action to be taken is to immediately stop fluid transfer.

This can be accomplished by closing control valves or shutting off the fluid supply to the source.

After dealing with the emergency, it is advisable to conduct a post-fault analysis to identify the root causes and implement any future preventive measures.

Contact our technical support for more information on this issue.

WHAT TO DO IF I SUSPECT A PROBLEM IN THE ROTARY JOINT BUT AM NOT SURE WHAT TYPE OF FAILURE?

If you suspect a problem in the rotary joint but are unsure of the nature of the fault, the following steps should be followed for effective resolution:

1 - Visual Inspection:

Perform a visual inspection of the rotary joint. Watch carefully for any leaks, visible damage, or abnormalities in its operation.

2 - Contact Customer Service:

In case you cannot clearly identify the problem, contact Johnson-Fluiten customer service immediately. Our team of experts is available to answer your questions and guide you through a preliminary diagnosis.

3 - Describe Symptoms:

Provide a detailed description of the symptoms or abnormal behaviors you have noticed in the rotary joint. This information will be useful for an initial assessment of the possible failure.

4 - Share Operational Details:

Report relevant operational details, such as operating pressures, temperature, type of fluid being transported, and any other significant operating conditions. These details will help the service team better understand the context.

5 - Via Photos or Video:

If possible, capture photos or videos of the rotary joint during its operation or highlight specific areas of concern. These visual materials can be invaluable for remote assessment.

Please feel free to call our support service : +39 023394091

WHY DOES A NEWLY MOUNTED JOINT LEAK?

The loss of a newly assembled rotary joint can be attributed to several factors, some of which may be temporary or related to the initial phase of use.

Here are some possible explanations:

Incorrect Installation:

Immediate leakage could be caused by incorrect installation of the rotary joint. Carefully check that the coupling has been installed following all instructions provided in the dedicated installation manual.

Initial Physiological Leakage:

Some rotary joints, especially those with special designs, may have an initial physiological leakage that reduces with time. This phenomenon is normal in the early stages of use and may be part of the running-in process of the coupling.

Running-in time:

Some couplings require a short run-in period before reaching maximum sealing efficiency. During this initial period, small leaks may occur that tend to decrease as the joint stabilises.

Presence of Dirt or Contaminants:

The presence of dirt, particles or contaminants in the fluid line or pipeline can compromise the tightness of the coupling. Ensure that the pipeline is clean and free of debris before installing the coupling.

If the leakage persists or is of concern, we recommend that you contact our customer service department for personalised assistance to ensure proper functioning of your Johnson-Fluiten rotary joint.