Improving rotary joint performance with efficient piping solutions

Flexible metal piping is used on the inlet and outlet connections of rotary joints to allow the movement of the joint itself and the thermal expansion of the pipes.

The consequences of inadequate piping should not be underestimated.

Inadequate installations can cause a number of problems, including:

-

- Excessive force applied to the joint body

-

- Accelerated wear of the guides in self-supported rotary joints

-

- Deflection of support rods in rod-supported rotary joints

-

- Failure of fasteners in nipple flanges and journal flanges

To show the relevance of hose installations, consider the following examples:

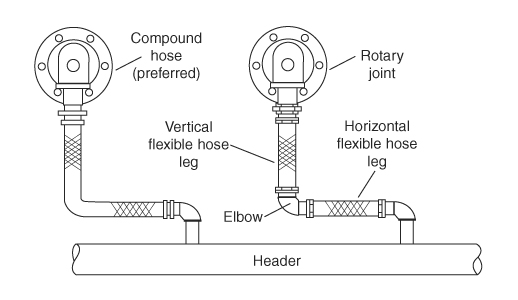

Flexible vertical hose + Flexible horizontal hose

Using a vertical flexible pipe allows the expansion of the header and balances out any misalignment between the rotary joint and the piping. At the same time, the horizontal part of the flexible pipe assists the thermal and hydraulic expansion of the vertical section, ensuring that high forces are not applied to the rotating joint.

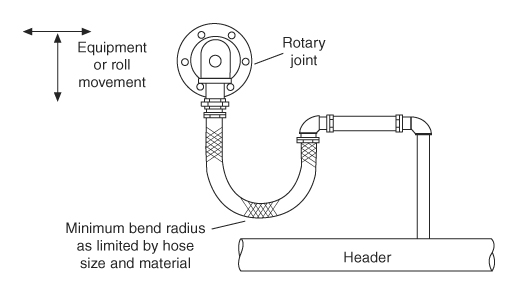

Bent flexible hose

This approach offers unparalleled flexibility in terms of pipe length, horizontal and vertical movement of the pipes and cylinder. It is important to emphasise that the pipe length in this example is often longer than what is actually required due to the minimum bend radius requirements. The minimum bend radius is determined by factors such as pipe size, material and the entity of the equipment movement.

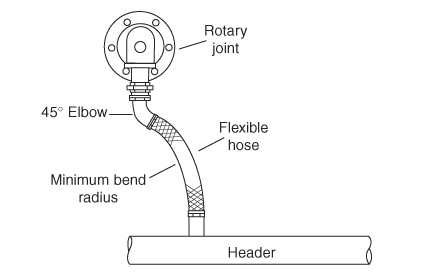

Flexible hose bent with 45° elbow

In this case, a single piece of pipe is used, which requires enough length to meet the minimum bending radius given by the pipe dimensions and material specifications. This arrangement minimises the hydraulic loads generated by the pipe due to the tolerance of length and space.

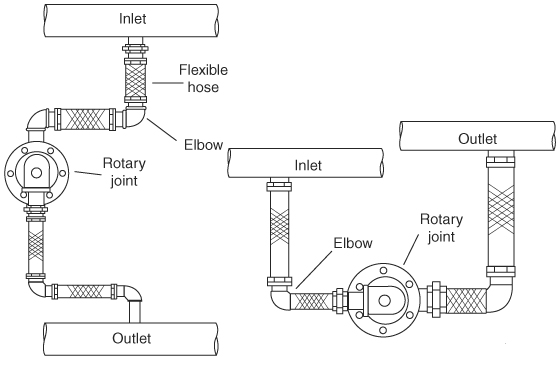

For optimal performance and efficiency, we recommend considering dual pass units that meet your specific needs. Our experts can guide you in choosing the ideal solution for your needs.

Choosing the right solution for your rotary joints

You can improve the performance of your rotary joints with our recommended flexible metal hose solutions. Experience the benefits of increased flexibility, efficient thermal expansion management and reduced stress on critical components. Rely on our expertise for optimal dual flow arrangements, ensuring uninterrupted operations and unparalleled reliability.

Contact us today to explore the possibilities and revolutionise your piping systems.

+39.023394091