Johnson-Fluiten and Kadant Johnson together offering the best solutions to the corrugated market.

The Corrugated and Paper & Pulp markets have always been a fundamental sector for Kadant Johnson and Johnson-Fluiten.

On these markets, where we are the undisputed leader, we work with the main manufacturers worldwide and with all the end users. Therefore, we are able to offer customized solutions and utilize our expertise and tradition to build up the best options with our high-quality products.

The first product that is most importantly supplied is the Rotary union, used to bring the steam inside the roller and to extract the condensate.

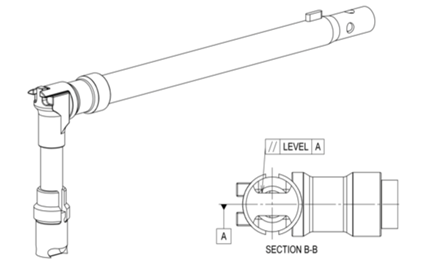

Within many years of experience on the field, the Kadant Group has developed a rotary union with unique characteristics for this market, the CorrPro Rotary Joint.

Kadant Johnson CorrPro Rotary Joint was the first rotary union to include an externally adjustable syphon clearance that is adjustable from outside the roll. This patented design allows the operator to adjust the clearance between the internal roll surface and the syphon vertical pipe after the joint and syphon equipment is installed.

The advanced CorrPro system is guaranteed to perform without maintenance from roll grind to roll grind when installed by Kadant Johnson or Johnson-Fluiten service teams. With these and other features, the CorrPro joint has become the worldwide OEMs preferred steam joint of wet end corrugating. The CorrPro steam joint is rated up to 450°F (243°C), 300 psig (20 bar), and 600 rpm.

The rotary unions are equipped with flexible pipes and syphons (stationary or rotating) for the passage of steam / condensate.

All our syphons are made on customer specific, taking into account their needs, wants and specifications required.

Specifically, in the Corrugated market, in addition to supplying rotary unions with the best technical and performance characteristics, we also offer a portfolio of other products. These series of products support the businesses improving their energy saving, efficiency and productivity.

Recently, we have developed and supplied quick couplings, to allow rapid replacements of the cylinder group. Kadant Johnson quick couplings have a special anti-drip system, which allows you to perform it without emptying the heating circuit.

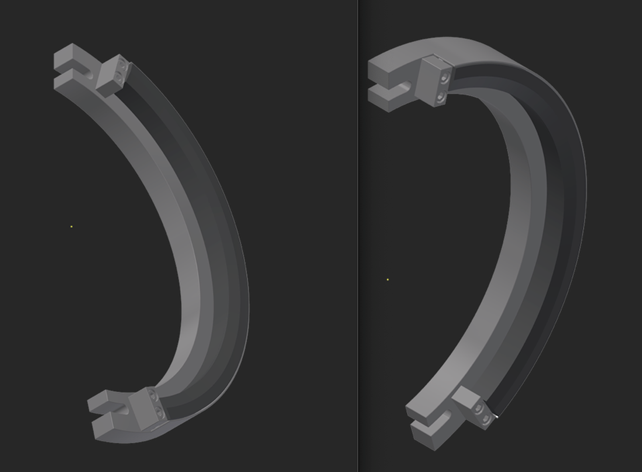

In addition to the temperature, a certain degree of humidity must be guaranteed to preserve the integrity of the cardboard sheet. To keep the heat constant in the chamber between the cylinder and the cover it is necessary to use a very special mechanical seal. Our mechanical seals in sectors are mounted directly on the cylinder covers or on special flange. They seal with the rotating part on the cylinder.

After more than 20 years, thanks to the perseverance of our colleague Luigi Rolfini, Johnson-Fluiten managed to enter again in the market with sectored mechanical seals. In this case, there is a cover around the lower and upper corrugating and press cylinders, where the sheet of cardboard passes to preserve a constant temperature.

The two sliding surfaces come into contact during the rotation of the cylinder, by means of a mechanical system present within the plant.

All in all to offer the best solutions on performance and energy saving for the corrugated industrial processes.

Contact one of our sales representatives and learn more about what this high-quality product can do for your corrugated business.