Innovative steam processes for CFT Group with Kadant rotary joints

CFT Group, a leading player in the food industry machinery business, offers state-of-the-art solutions; equipment and complete production lines, manufactured in its Parma facilities, are implemented in companies all over the world.

Reliable and consistent operation is aided by careful design, flawless service and, of course, the choice of premium materials and components.This is why CFT Group's partner for rotary joints is Johnson-Fluiten.

For 80 years, CFT Group, a company based in Parma with customers around the world, has been producing solutions for food and beverage processing and packaging.

Since 2021, the company has been part of ATS Corporation, a world leader in industrial automation: the synergy with this large company allows it to offer state-of-the-art solutions that incorporate advanced technologies.

CFT Group is appreciated by major food companies for its tailor-made systems and outstanding service; many installations are located abroad and it is important that they operate perfectly even in the long term. For this, the choice of quality materials and reliable components is crucial.

A lot of CFT Group's innovative solutions use rotary joints supplied by Johnson-Fluiten, a company leading the industry in fluid management solutions for industrial machinery: says Eng. Marco Galeazzi, Technical Product Manager at CFT Group.

A recommended choice

For Johnson-Fluiten, the food industry has always been a focus: the company allocates resources to research aimed at creating and refining solutions for this segment and offers a wide range of rotary joints to meet the extensive and different needs of the Food & Beverage industries. An investment that has also paid off in terms of notoriety.

|

|

“We chose Johnson-Fluiten because we were already familiar with their reputation in the industry and had heard positive things about them from other companies,” Galeazzi explains; “in addition, the quality and reliability of their products became clear when compared with other manufacturers' solutions” |

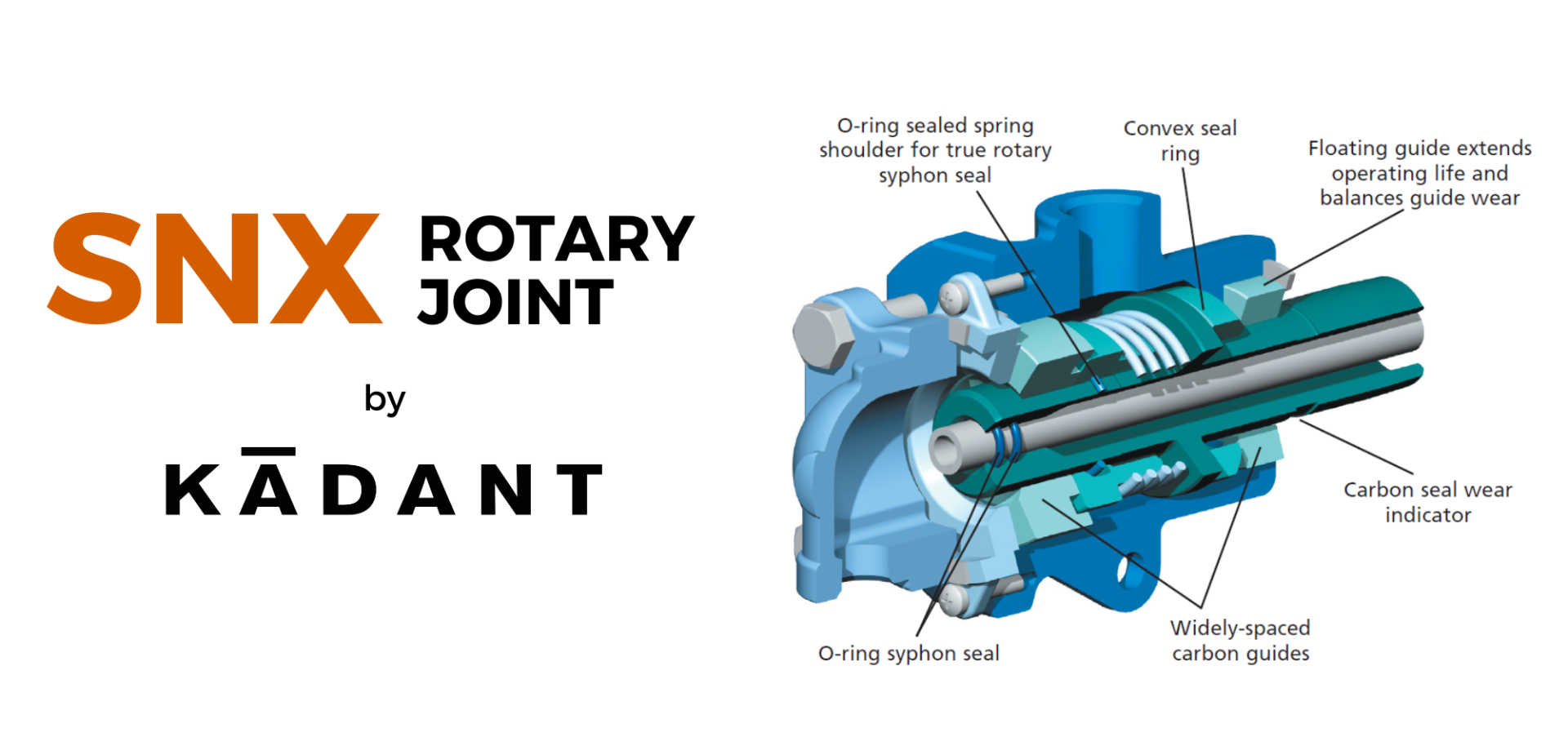

SNX, the mastering of steam

Among the large number of designs available in the Johnson-Fluiten catalog, CFT Group chose SNX rotary joints manufactured by Kadant, a global leader in the production of rotary joints for steam handling. The rotary joints chosen are designed to be used with fluids such as diathermic oil and steam, an ideal option for the food processes handled by the systems produced by CFT. Few suppliers can design and manufacture rotary joints capable of operating with steam under comparable conditions: SNX joints withstand steam temperatures of up to 288°C, pressures of up to 35 bar and rotational speeds of up to 450 rpm.

Given the great deal of experience in paper mills, where steam is widely used, Kadant Johnson (the company that in partnership with Fluiten Spa originated Johnson-Fluiten) is a benchmark in the segment of rotary joints for steam handling: in this specific market, competitors struggle to offer solutions at the same level. SNX unions do not use bearings but graphite seals, making them ideal for high temperatures; they are also available as standard unions in sizes up to 4".

|

|

“After considering several options available on the market, we chose SNX unions because they were the most suitable for our needs,” confirms Galeazzi, who emphasizes, "The support team recommended this solution to us based on the specific requirements of our production processes. The tests performed confirmed that SNX joints offer superior performance in terms of reliability and durability, which are essential factors for our production lines” |

Perfect for jam

SNX rotary joints are highly appreciated in the food industry as the manufacturer is able to meet stringentrequisiti FDA (Food and Drug Administration) and EFSA (Autorità europea per la sicurezza alimentare) requirements; but that's not all. These components equip special seals that allow the joint to operate maintenance-free for up to three times longer than traditional resin seals.

Perfect compatibility with processes that require high temperatures allows SNX rotary joints to find use in the processing of jams and other preparations used in the confectionery industry such as toppings, where ensuring uniform heating is critical to product quality.

This is why CFT group selected SNX unions for rotating coils used in the production of jams and other fruit-based product. “The use of these components has brought many benefits, including increased operational efficiency, reduced downtime, and easier and less frequent maintenance,” Galeazzi explains. “Due to their high build quality, we have seen an improvement in process stability and longer component life compared to other solutions tried in the past."

Topping it off : support

But it's not just a matter of performance: quality excellence alone would not be enough to guarantee the satisfaction of companies that approach Johnson-Fluiten.

Johnson-Fluiten's team of technicians can understand the customer's needs and suggest the best solution for each production process: the fine design of the joints makes it possible to minimize maintenance requirements.

A combination of expertise and readiness that has been appreciated by CFT Group: “Johnson-Fluiten's technical support and advice have been important in both the pre-sales and post-sales stages,” Galeazzi confirms in fact. "The support team supported us in choosing the most suitable product, providing us with all the necessary information for optimal integration into our systems. The after-sales support was also quick and effective”.

A fruitful collaboration

“We are fully satisfied with the collaboration with Johnson-Fluiten, both for the quality of the products and the level of service offered,” Galeazzi concluded.

CFT group thus joins the long list of successful companies that have been able to appreciate, in addition to the reliability and toughness of the products, the listening skills and closeness to customer needs that are distinctive features of the Johnson-Fluiten offering.

Author of the article

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091