Innovating to exceed limits: new calendering frontiers for Comerio Ercole with Johnson-Fluiten rotary joints

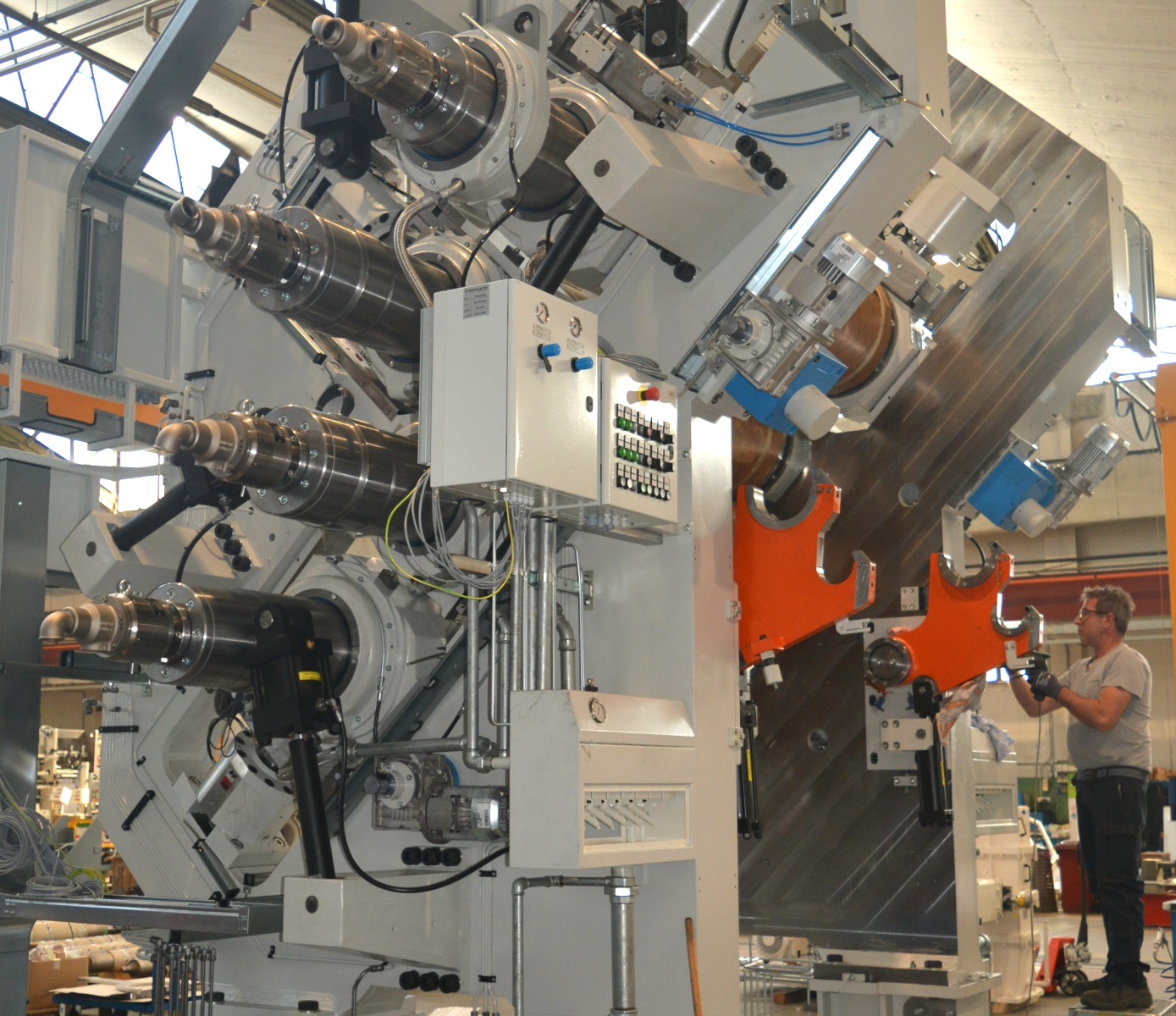

Comerio Ercole is a leading player in the rubber, plastic and non-woven machinery segment. The company is renowned not only for the reliability of its equipment, but also for its ability to innovate.

Two testing and research laboratories help to ensure that the company is always at the cutting edge, also thanks to the excellent solutions provided by Johnson-Fluiten

Comerio Ercole has a success story lasting more than 130 years: from its beginnings as a craftsman's business in 1885, it has developed into one of the world's leading manufacturers of machines and systems for processing rubber, plastic, woven-non-woven and other sheet materials that require to be compressed, levelled and processed by calendering.

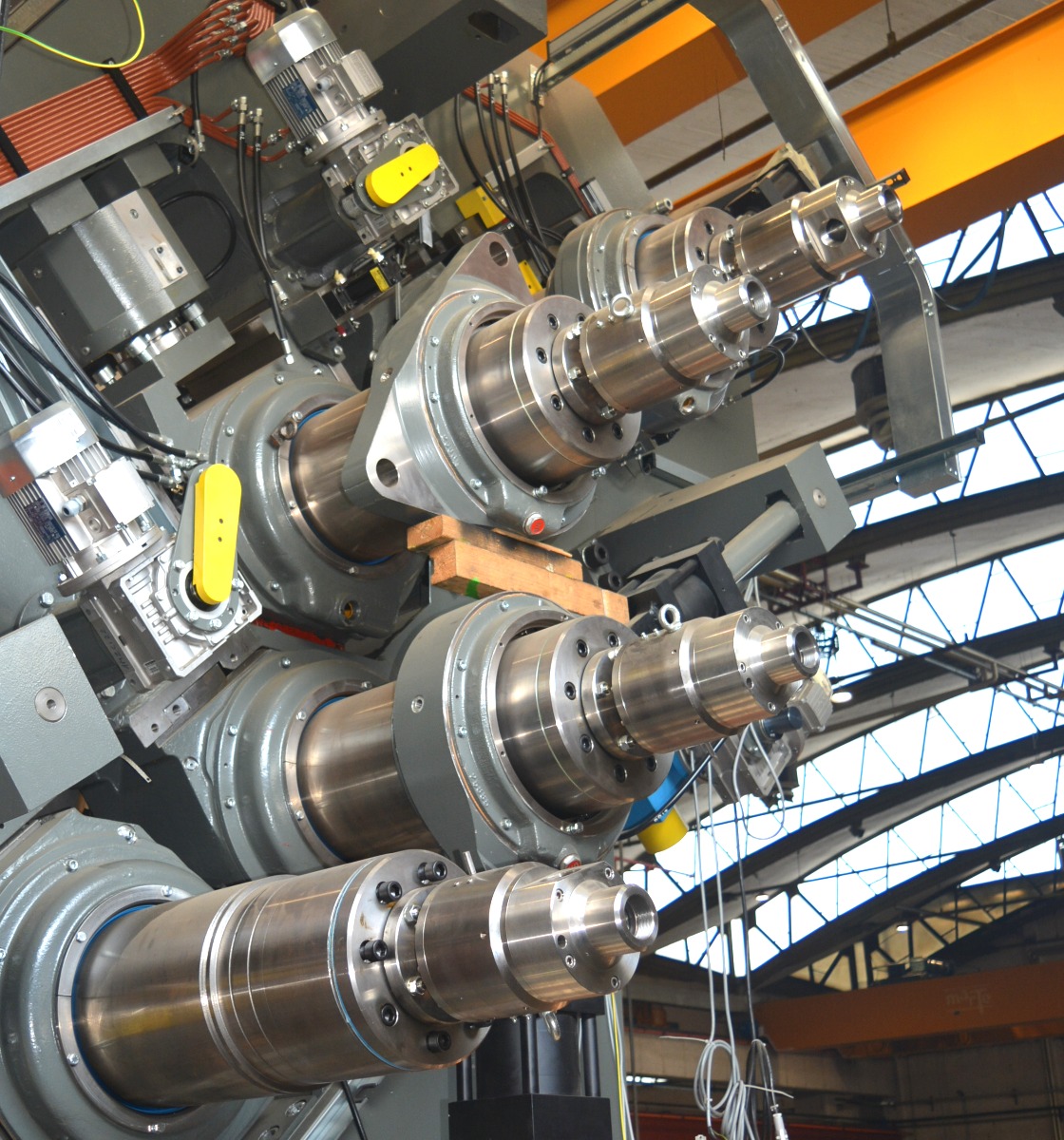

Among Comerio Ercole's strengths that have helped establish its excellent reputation is certainly its incessant research and development activity: constant experimentation in the process and material areas allows the company and its customers to achieve highly innovative results. This is possible above all thanks to the efficiency of the company's two in-house testing and experimentation laboratories, whose perfect functioning is guaranteed by the selection of state-of-the-art components, such as the rotary joints manufactured by Johnson-Fluiten.

Pre-competitive research development

The research and development laboratories are equipped with state-of-the-art facilities for simulations on machinery, processes and materials. A team of qualified professionals develops and coordinates projects that lead customers to competitive solutions and stay one step ahead of the competition. The effectiveness of the results achieved is proven by awards from the Ministry of Scientific Research and the Lombardy Region

Comerio Ercole's test and development centres were created to create and test machinery that works beyond the usual limits of temperature, speed and pressure; thus, it is possible to verify the workability of particular processes requested by customers and, in the event of a positive outcome, to create equipment that enables scale production.

Competence and quality control

As Simone Aicardi, Comerio Ercole's Chief Technical Officer, explains;

“'for many years Johnson-Fluiten has been our supplier of choice for rotary joints: perfect for machines that perform standard machining, they are also particularly valuable when it comes to testing machines that offer exceptional performance”.

In conventional calendering machines, the most commonly used Johnson-Fluiten rotary joints are the R-series; components that handle water or diathermic oil, whose performance has been carefully designed for cooling and heating applications for plastic or rubber-based products. These standard unions are also designed with the aim of achieving the best cost/benefit ratio available on the market for this type of product.

But when it comes to equipping special machines in testing laboratories, as environmental conditions are extreme and change rapidly and frequently, it is necessary to rely on tailor-made solutions

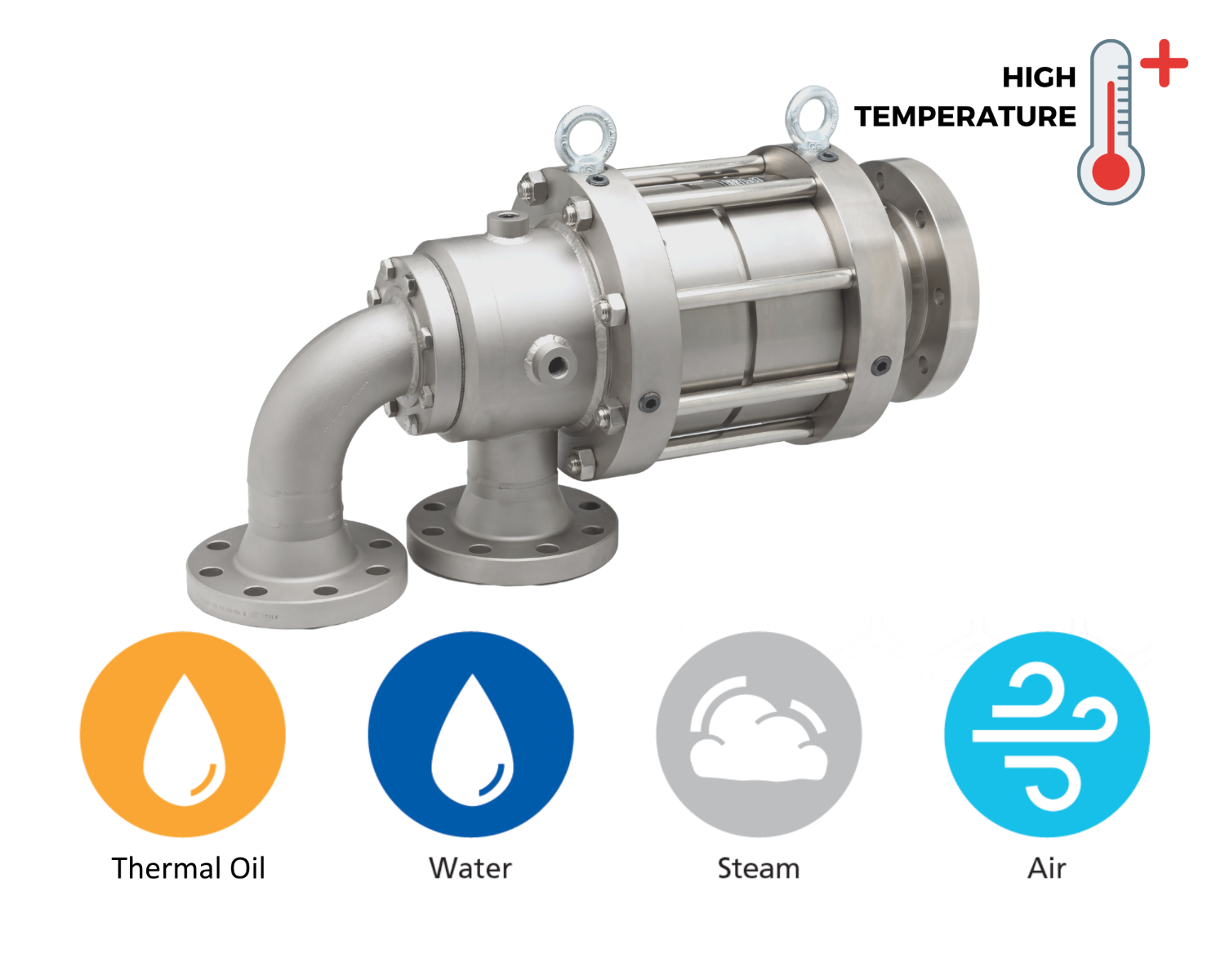

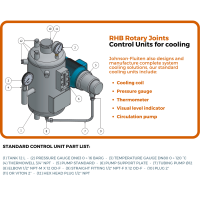

To handle temperatures of up to 400°C, which are necessary for calendering materials such as carbon fibres, graphene or other experimental elements used, the rotary joint that Johnson-Fluiten offers is the RHB joint.

The right solution for high temperatures and high speeds

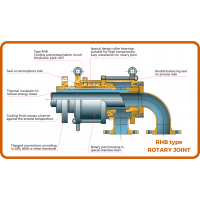

The RHB series rotary joints are designed to work at very high temperatures, which can be achieved by using thermal oil, in applications that also require high rotational speeds of up to 2,900 RPM.

This performance can be achieved by using two special balanced mechanical seals and bearings with closed-circuit oil cooling. For safety reasons, it is absolutely necessary to avoid any leakage of the process fluid into the atmosphere; a condition made possible by the double mechanical seals with pressurised barrier used in Johnson-Fluiten's RHB couplings.

The main features of these unions, which represent a real advantage for the end customer, and which have allowed Johnson-Fluiten to become a historical parnter of Comerio Ercole, can be listed:

-

(1) - The life cycle of the sealing rings tested up to 20,000 hours

-

(2) - The lack of bellows seals, which excludes the possibility of catastrophic leaks

-

(3) - The thermally stabilised roller bearings that guarantee a long service life and can withstand high axial and radial loads

When versatility is key

For laboratory tests, Comerio Ercole relies mainly on customised RHB unions, which perfectly meet the special application requirements and are supplied quickly

“In the laboratory, we can decide to change the heating fluid - from diathermic oil to steam, for example - to see which solution brings the best results, in terms of compactness, surface finish or other product characteristics," continues Aicardi. "With Johnson-Fluiten rotary joints, it is not necessary to change the component to carry out these tests: they are perfectly suited for all situations”.

After-sales service: the flagship of Johnson-Fuiten

In addition to the reliability and versatility of the unions, Comerio Ercole appreciates the ability to offer quick and decisive technical support:

“Johnson-Fuiten joints are strong and malfunctions are very rare, but if we need to do something, we have to guarantee continuity of production for our customer wherever he is. And since Comerio Ercole machines are installed all over the world, I really mean everywhere. From this point of view, the extensive service network of a multinational like Johnson-Fluiten is a guarantee".

For Comerio Ercole, the partnership withJohnson-Fluiten proves to be a winning one: products that are perfectly functional for the various requirements and impeccable service are the basis of a well-established and long-lasting partnership

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091