How to Choose a Rotary Joint?

Read this content to understand how to choose the ideal rotary joint for your industrial application!

In the industrial environment, efficiency and process optimization are essential to maintain competitiveness and ensure maximum productivity.

Among the key components for managing fluids from stationary to rotating parts are rotary joints. These devices play a crucial role in a wide range of applications, ensuring the proper heating or cooling needed in industrial processes.

Choosing the right Johnson-Fluiten rotary joint may seem complex, but by following this guide, you will be able to identify the most effective solution for your specific needs.

In this guide we will provide two ways for you to be able to select the rotary joint most appropriate for your needs;

1 - Selection By Application Sectors

2 - Selection by Operational Variables

Selection By Application Sectors

Selecting the appropriate rotary joint requires a thorough understanding of the specific operational needs of each industry. With a wide range of products and the ability to customize, companies like Johnson-Fluiten are able to offer optimal solutions that improve the efficiency, safety and sustainability of industrial plants.

The right choice not only improves overall performance, but also helps optimize production processes, ensuring greater reliability and durability. Below are some suggestions:

Paper and Paper Mills:

The paper industry benefits greatly from rotary joints in managing water and optimizing energy consumption. Products such as those offered by Kadant, distributed by Johnson-Fluiten, are essential for improving efficiency and environmental sustainability:

Textile:

In textile and nonwoven production, rotary joints support critical steps such as fiber formation, stretching and finishing. Their ability to handle fluids under high precision and reliable conditions is essential to reduce energy costs and increase production efficiency:

Rubber and Plastics:

In the rubber and plastics industries, rotary joints facilitate key processes such as mixing and extrusion. They are designed for reliability and durability, helping to reduce energy costs and improve production efficiency:

Chemical and Pharmaceutical:

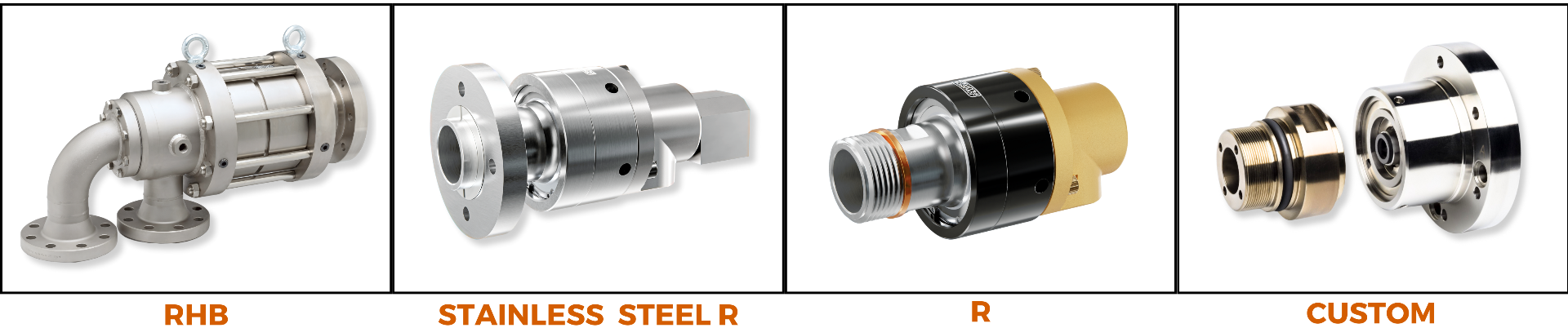

These industries require rotary joints that offer uncompromising precision and reliability. Advanced materials such as Hastelloy C22 ensure corrosion resistance and optimal performance even under extreme conditions:

- STAINLESS STEEL ROTARY UNIONS R

Steel:

In the steel industry, rotary joints are essential for heavy industrial processes. They are designed to withstand extreme operating conditions, ensuring the safe and reliable transfer of various fluids:

Food:

The food industry relies on rotary joints for drying, mixing, packaging, heating and cooling processes. Rotary joints must meet high standards, such as FDA and ATEX certifications, to ensure safety in food production processes:

- STAINLESS STEEL ROTARY UNIONS R

Machine Tools:

Rotary joints also find application in the machine tool industry, where high precision and reliability are required. They are essential for handling fluids in high-speed machinery and ensuring uniformity of rotation:

Energy Sector:

In the dynamic energy sector, the choice of reliable and durable rotary joints is crucial. Johnson-Fluiten rotary joints offer customized solutions that meet the high-pressure, high-speed fluid handling demands typical of energy production. They are designed to integrate seamlessly with existing infrastructure, promoting innovation and sustainability:

Selection by Operational Variables

Rotary joint selection depends on 6 key factors:

1 - Pressure - INDICATED IN "BAR" or "PSIG”

Fluid pressure affects the seal and/or bearings of the rotary joint. Higher pressure will limit the number of joints that can be used.

2 – Speed - INDICATED IN "RPM”

Rotational speed affects bearings and sealing. Seals seal the fluid between the rotating part of the machine and the stationary part. They are subject to friction and are wear parts.

3 – Temperature - INDICATED IN °C or °F

Temperature affects many parts of the rotary joint: seals, bearings, and choice of materials. The mechanical seal often reaches 340°C, for o-rings and lip seals the temperature is determined by the limits of the material of which they are composed. The temperature is influenced by the temperature of the fluid and additional friction in the mechanical seal and bearings.

4 – Fluid - e.g. AIR / WATER / OIL / STEAM / MQL…

The fluid influences the seal. Some sealing materials do well with water while others with oil or air. Small amounts of fluid will leak between the rotating and stationary parts: depending on the choice the fluid will lubricate the seal and improve performance, in other applications in this case the seal will perform worse.

5 – Volume - INDICATED IN "INCHES" or "MILLIMETERS”

Determines the size of the passages and thus the size of the joint to be used. Important to consider is the velocity of the fluid within the passage.

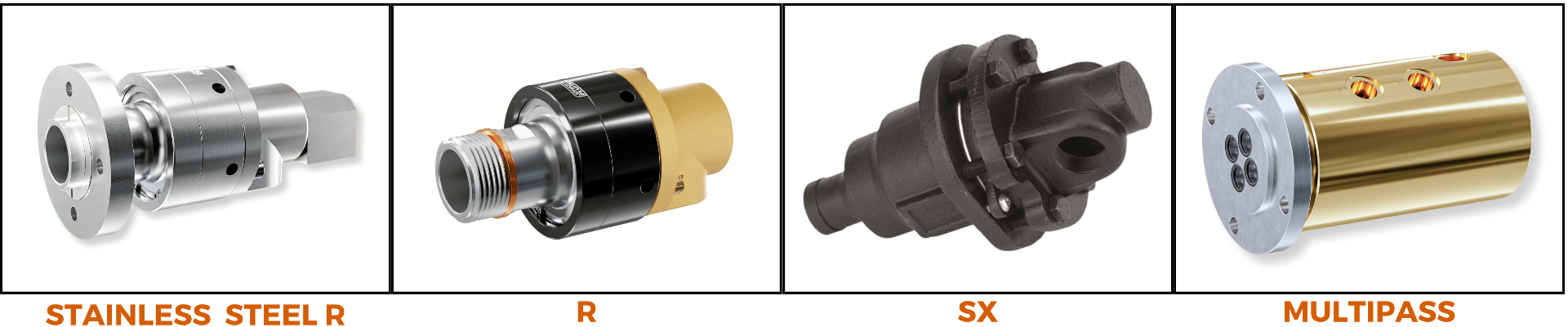

6 - Number of passes - INDICATED WITH A NUMBER

Determines the configuration of the joint. Rotary joints often have 1 or 2 passages and have a wide range of sealing materials available. When 3 or more passages are required, lip seals and o-rings are used.

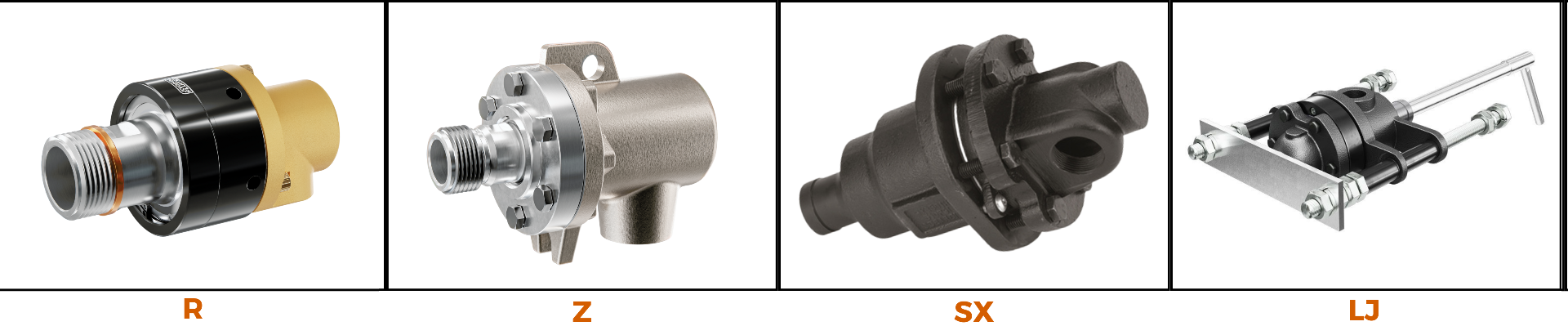

Our Product Range

Johnson-Fluiten offers a wide range of rotary joints designed to meet the specific needs of each industry. From maximum resistance to high pressures and temperatures, to compatibility with various fluids and volumes, our catalog is designed to offer a suitable solution for every industrial application.

Are you ready to find the ideal rotary joint for your application? Contact our sales department for customized support and find out how our products can optimize your industrial processes.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091