What makes a rotary joint fail?

Rotary joints are essential components, in many industrial applications, to transfer fluids under pressure between a fixed and a rotating part. However, like any mechanical component, they can be vulnerable to failure or malfunction.

Identifying and understanding the main causes of these problems is crucial to extend their service life, improve performance, and reduce maintenance costs. Here, we explore the most common causes of failures in rotary joints and how to prevent them.

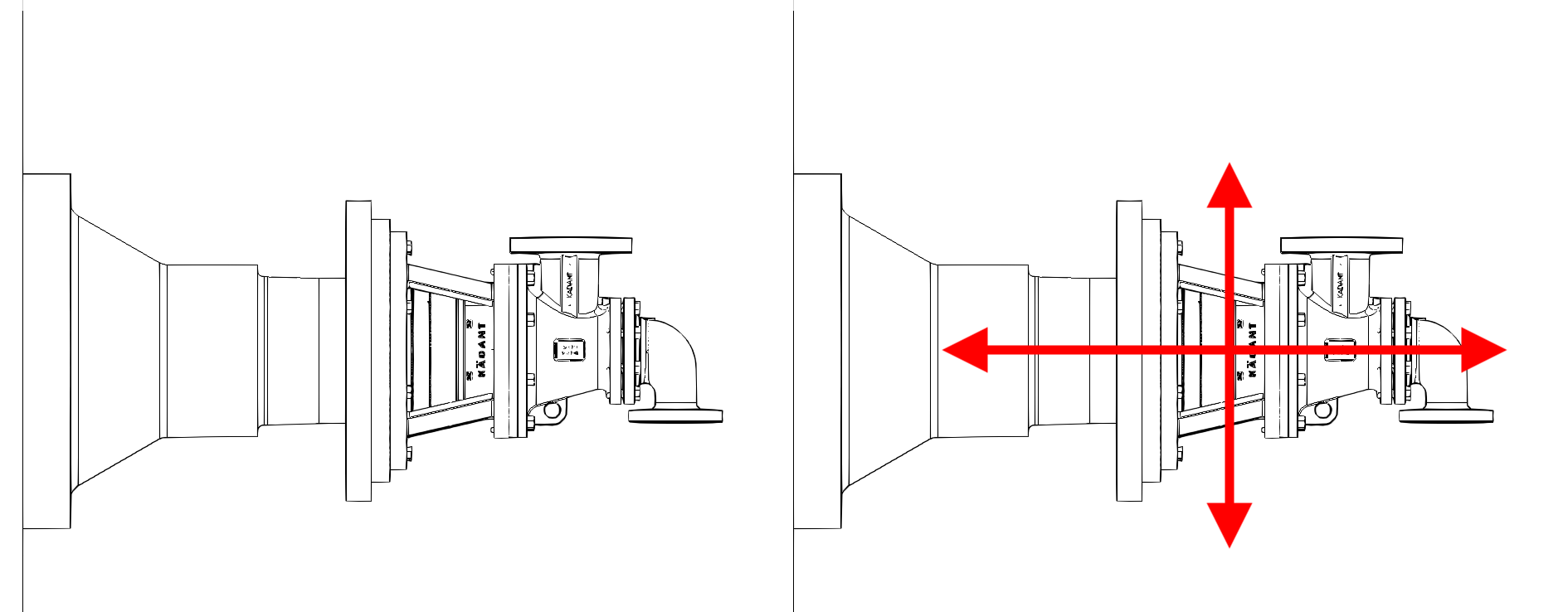

1. Incorrect Installation

Improper installation is one of the most common causes of malfunction in rotary joints. Common faults include:

1- Improper alignment: Poor alignment between the joint and the cylinder or spindle can generate mechanical stresses and accelerate wear of internal parts.

2- Wrong tightening: Too high or too low a torque during installation can compromise the sealing of the joint.

3- Failure to follow assembly instructions: Ignoring specific details provided by the joint manufacturer can lead to critical errors.

How to Prevent this?

Ensure that installation is done strictly according to the manufacturer's instructions. Whenever possible, rely on qualified personnel to ensure proper installation.

Learn more by visiting our section on installation instructions for rotary joints

https://johnson-fluiten.com/it/cataloghi.html

2.Wear and tear of Internal Parts

With extended use, the internal components of the joint, such as seals, bearings, and sliding surfaces, can deteriorate. Wear and tear is inevitable but can be accelerated by:

- Lack of proper lubrication.

- Aggressive environments.

- No preventive maintenance.

How to Prevent this?

Schedule regular maintenance to check the status of internal parts and replace them when necessary. In addition, choosing wear-resistant materials according to the specific application can significantly reduce the risk of failure.

Find out how our team of specialists can support you in maintenance planning and request a free consultation

https://johnson-fluiten.com/en/blog/post/joints-rotating-as-new-maintenance-and-reconditioning

3. Improper Utilization

A rotary joint is designed to operate within defined parameters, such as pressure, temperature, speed, and fluid type. Exceeding these limits can lead to:

1- Deformations of components.

2- Leakage of seals.

3- Mechanical overload

How to Prevent this?

Refer to the technical specifications of the joint before use to ensure that it is suitable for operating conditions. If in doubt, contact the supplier for advice.

Contact our team for support in choosing the right rotary joint for your needs

https://johnson-fluiten.com/en/contacts.html

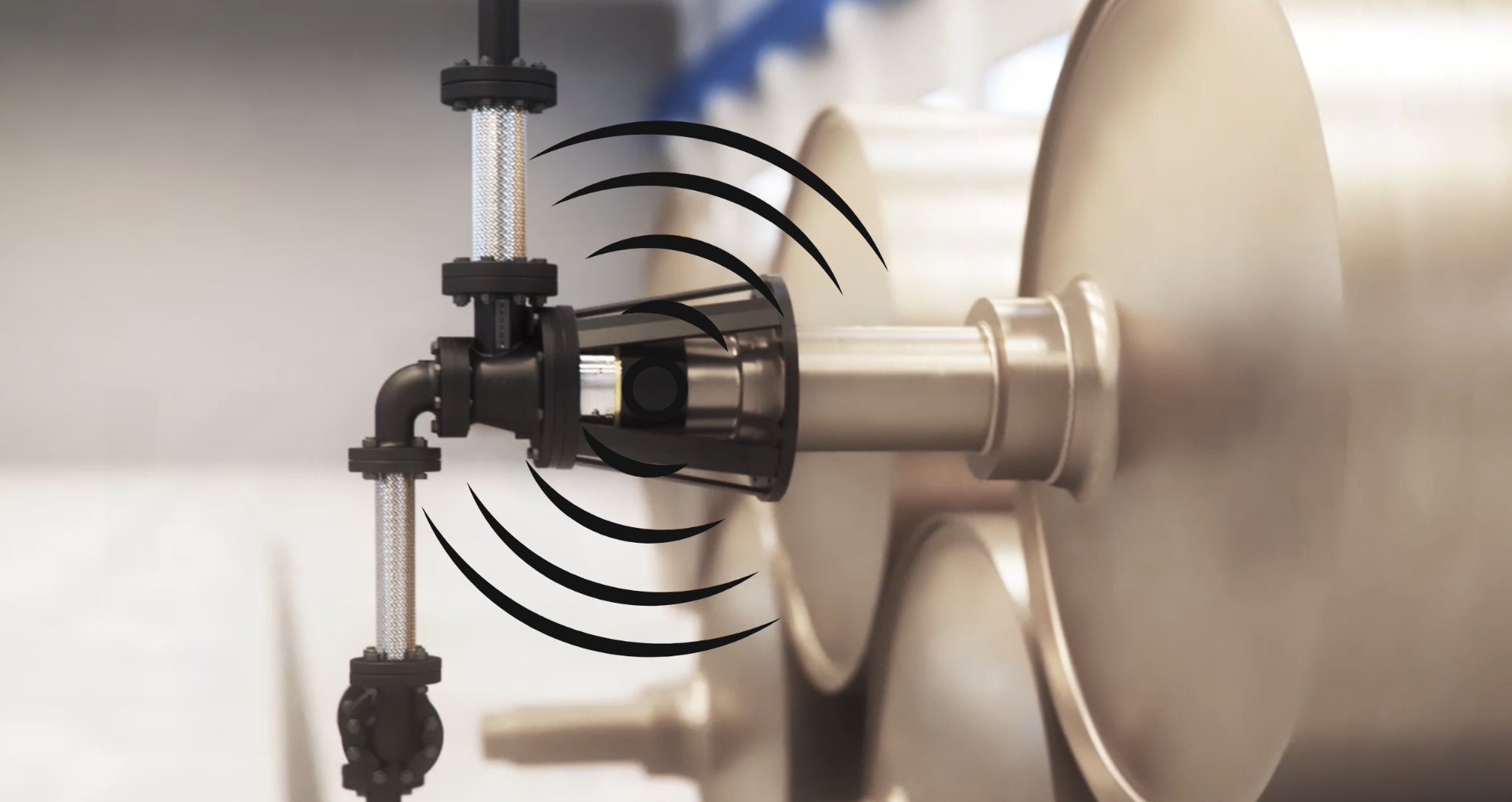

4. Excessive Vibration

Vibrations can quickly damage rotary joints, especially when they exceed acceptable levels. These can result from:

- Imbalances in rotating components.

- Incorrect alignments.

- Non-optimal installation

How to Prevent this?

Performing proper joint assembly and periodic alignment checks can help maintain the stability of the entire system.

Do you think that the rotary joint is not installed correctly? Contact our technical team for support and customized solutions.

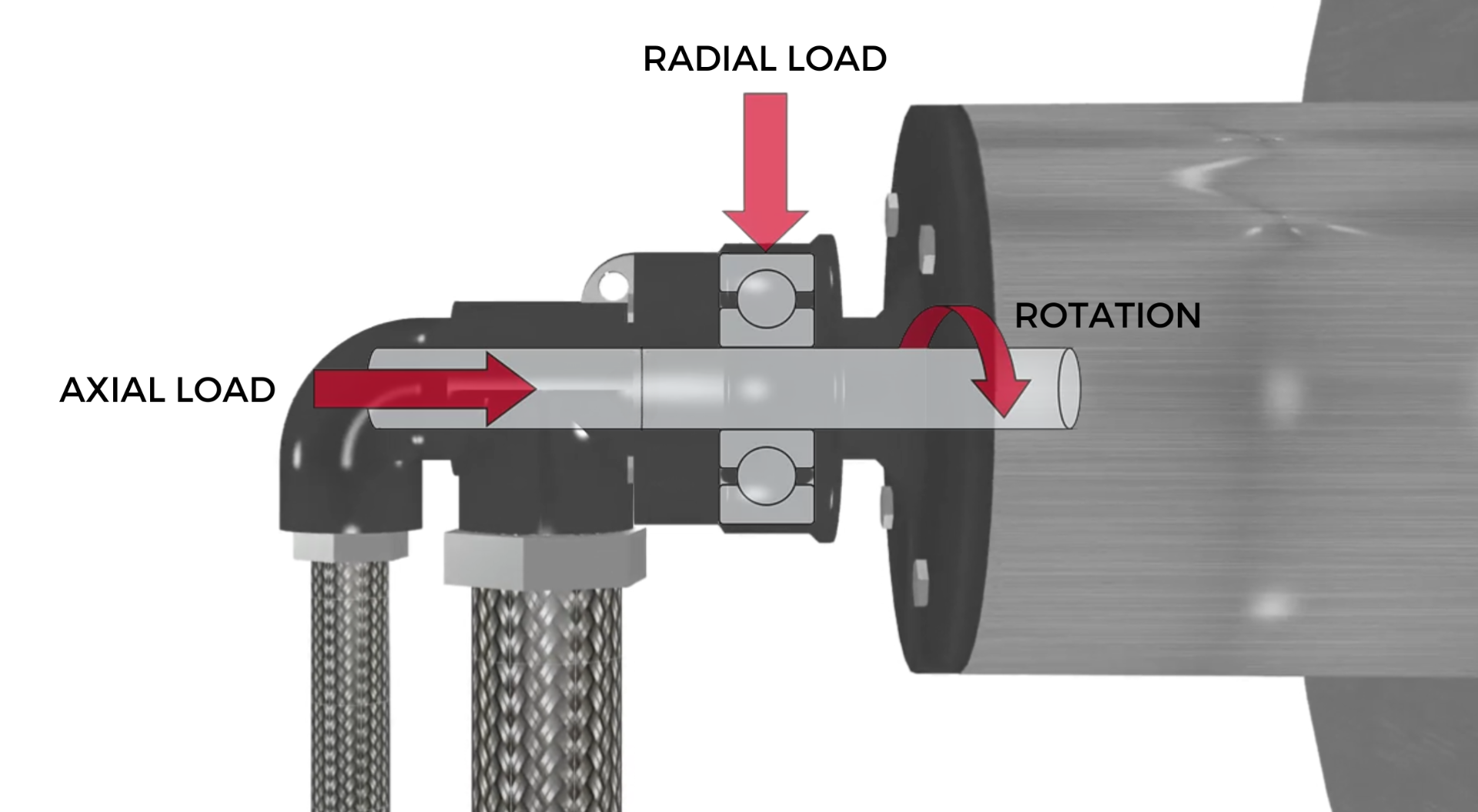

5.Radial and Axial Loads

Radial and axial loads are forces acting perpendicularly and parallel to the axis of rotation, respectively. Excessive loading can:

1- Compromise the tightness of the joint.

2- Accelerate bearing wear.

3- Causing mechanical failure.

How to Prevent this?

Ensure that there are no mechanical constraints that limit the normal movement of the joint. In case of particularly heavy applications, consider different installation methods. Also remember that the application of axial and radial loads on rotary joints should always be avoided, as such loads can critically affect the performance of the component.

Conclusion

Rotary joint failures can be avoided in most cases with a combination of proper installation, preventive maintenance, and adherence to operating specifications.

Johnson-Fluiten, a long-time leader in rotary joints for industry, offers reliable solutions and formidable technical support to ensure components operate at peak performance.

Learn more about our products and services

https://johnson-fluiten.com/en/rotary-unions.html

Author of the article

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091