News KO

-

For many years, the rotary joints used in these machines have been manufactured by Johnson-Fluiten, a supplier valued for its ability to conform to the stringent specifications required by regulations for these sensitive industries. 3V TECH is a well-known name in the segment of machinery for the chemical-pharmaceutical industry: it has been operating in this complex sector for about 50 years and has been supplying companies all over the world with standard and tailor-made solutions intended for the pharmaceutical and fine chemical sectors. The range of machinery and equipment developed by 3V Tech is wide and ranges from tanks, heat

-

With pressure equipment, adherence to standards is important for ensuring safety, performance, and legal compliance. At the core of the regulatory environment stands the Pressure Equipment Directive (PED), a set of rules established by the European Union to regulate the design, manufacture, testing and conformity assessment of pressure equipment. Why is PED Crucial? The Pressure Equipment Directive (PED) plays a crucial role in ensuring the safety, standardization, and legal compliance of pressure equipment within the European Union (EU). Firstly, PED prioritizes safety by establishing specific requirements for pressure equipment, aiming to mitigate the risks associated with accidents, injuries, and property damage resulting from equipment failure. Secondly, by providing a harmonized set of rules, PED ensures uniform safety standards across the EU, facilitating the smooth movement

-

апр 02 2024

How to Choose a Rotary Joint?

Read this content to understand how to choose the ideal rotary joint for your industrial application! In the industrial environment, efficiency and process optimization are essential to maintain competitiveness and ensure maximum productivity. Among the key components for managing fluids from stationary to rotating parts are rotary joints. These devices play a crucial role in a wide range of applications, ensuring the proper heating or cooling needed in industrial processes. Choosing the right Johnson-Fluiten rotary joint may seem complex, but by following this guide, you will be able to identify the most effective solution for your specific needs. In this guide we will provide two ways for you to be able to select the rotary joint most appropriate for your needs; 1 - Selection By Application Sectors

-

In the industrial environment, innovation and reliability are two fundamental pillars that lead to success and operational efficiency. From this perspective, Johnson-Fluiten rotary joints represent a true revolution, thanks to a distinctive feature that makes them unique on the market: the Quick Replacement Design (QRD). What makes QRD so special and essential for companies that want to get the most out of their industrial machines? The answer lies in the quality and innovation brought by the partnership with Fluiten spa, the acknowledged leader in the design and manufacture of mechanical seals. -- CONTACT US -- ASK FOR A QUOTE --

-

For decades, Nordmeccanica, a company known worldwide for its laminating machines and metallisation machinery, has been using Johnson-Fluiten components to give its solutions the reliability its customers expect. A long-lasting partnership based on the perfect match of Johnson-Fluiten components to Nordmeccanica's needs, the very low maintenance requirements and the supplier's willingness to meet every customer request. For more than 45 years, Nordmeccanica, a company from Piacenza but present in more than 87 countries around the world, has been designing and manufacturing machinery for coating, laminating and metallisation of

-

Achieving optimal efficiency and enhancing production capacity are cross-industry objectives. Kadant Johnson's turbulator bars stand as a benchmark to modern technological advancements, refocusing the drying process of paper drying. Enhancing Drying Uniformity and Capacity Modern paper mill operations will benefit from our Axial Dryer Bars; they are designed to elevate drying uniformity and increase the capacity of dryer-limited machines. These bars offer a great solution for boosting production or reducing operating steam pressures. Precision Placement for Maximum Impact Strategically placed within the dryer, our bars generate resonant waves in the condensate film, creating turbulence even at high speeds. The result? A remarkable up to 50% increase in heat transfer efficiency compared

-

In the current business context, there are many manufacturers of fluid management components that target the machine builder market. But not many of them can claim to have a track record of success in designing customized solutions for specific applications that are truly capable of providing real and measurable benefits How we achieve, with our rotary joints, a leading place among the most important manufacturers of production lines in the plastics and rubber industry? Let's find out the answer by analyzing the case of the development of the RX rotary joint with a "special head" for a major international customer that manufactures industrial plastic machinery; this project helped to simplify the customer's handling of components and ensured REAL & VERIFIED savings in time, energy and

-

дек 14 2023

DELFO COLOMBO; FOUNDING THE FUTURE

The 20th anniversary of the company's foundation is an ideal occasion to remember the extraordinary professional and individual personality of Alberto Delfo Colombo, who sadly passed away a few months ago, and who was the real driving force behind the establishment and success of Johnson-Fluiten. The Johnson-Fluiten project comes from the distinctive identities and features of the two companies that shaped it: Fluiten and Kadant Johnson. Fluiten is a historic Italian company representing excellence in the precision mechanical industry. Since 1961 it has produced Mechanical

-

In 20 years of work, Johnson-Fluiten, a leading company in the rotary joint industry, has proven the excellence of its solutions: the wide range of products, capable of satisfying the most demanding requirements in many different applications, is combined with the ability to manufacture rotary joints quickly and tailor-made to specific customer requirements. The company is the result of a joint venture between two well established companies in the sector, Fluiten Italia Spa and Kadant Johnson: in this interview Fulvio Colombo, General Manager of Fluiten Italia Spa, and Mark Strik, Vice President for Europe of Kadant Johnson's Flow Control sector, describe the genesis, growth and prospects of the company twenty years after the foundation of Johnson-Fluiten. A synergic collaboration

-

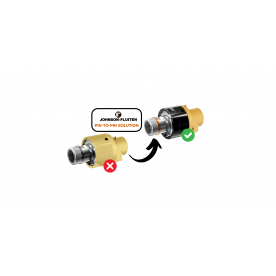

With the cancellation of DP and DX rotary joint lines, you may find it difficult to source the components required to operate your industrial machinery WE HAVE THE SOLUTION FOR YOU Johnson-Fluiten's R-Series rotary joints and Kadant Johnson's RX-Series rotary joints are known for their compatibility with the most widely used rotary joints on the market. You don't have to worry: the R-Series and RX-Series rotary joints are fully compatible with competitors' DP-Series and DX-Series joints, and offer you a pin-to-pin replacement solution*.