maintenance

-

For over a decade, Babbini has been using Johnson-Fluiten rotary joints in its presses: solutions that have proven to be reliable, flexible, easy to maintain, and supported by an ever-present technical service. A relationship of trust that has contributed to the reputation for excellence of the machinery manufactured by this historic Italian manufacturer. Founded over 160 years ago, Babbini specializes in the design and construction of dehydrating presses for the sugar industry. Its high-efficiency solutions, based on counter-rotating twin screw systems and hollow shafts, are now used worldwide to optimize liquid-solid separation processes. Babbini machines, often customized to customer requirements, are distinguished by their high operational efficiency, even under harsh conditions. Attention to components

-

Two companies with many things in common, from the focus on research and development to customized consultancy, as well as control over all stages of production to ensure that the proposed solutions meet the highest standards. Similarities that led Luigi Bandera to find in Johnson-Fluiten a valuable partner for the supply of components that make the production process more efficient Costruzioni Meccaniche Luigi Bandera Spa is a leader in the plastic extrusion industry: the founder, after whom the company was named, was a pioneer in the sector, building in the immediate postwar era a screw extruder for PVC tubes and profiles that was highly innovative for the time. From 1947 to the present, a lot of ground has been covered: in the decades

-

In the industrial environment, innovation and reliability are two fundamental pillars that lead to success and operational efficiency. From this perspective, Johnson-Fluiten rotary joints represent a true revolution, thanks to a distinctive feature that makes them unique on the market: the Quick Replacement Design (QRD). What makes QRD so special and essential for companies that want to get the most out of their industrial machines? The answer lies in the quality and innovation brought by the partnership with Fluiten spa, the acknowledged leader in the design and manufacture of mechanical seals. -- CONTACT US -- ASK FOR A QUOTE --

-

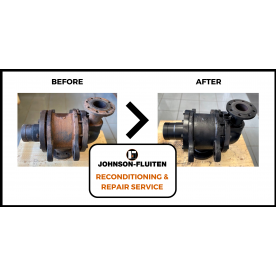

As good as new. Our rotary joint reconditioning service gives the product perfect functionality "as if it had just left the factory". We are so confident in the result that we guarantee it. All mechanical components have a 'life cycle' and when they are used in particularly heavy-duty applications, for parts exposed to normal wear and tear, it is necessary to carry out some checks and professional maintenance so that the system always works at its best. Let's take one of our customers as an example who treats animal waste (or also called 'rendering') with its plants. Treating slaughterhouse waste such as bones, blood, feathers, carcasses, leather, and turning them into bone and