Advanced Solutions for the Chemical-Pharmaceutical Industry: The Excellence of Johnson-Fluiten Rotary Joints

For many years, the rotary joints used in these machines have been manufactured by Johnson-Fluiten, a supplier valued for its ability to conform to the stringent specifications required by regulations for these sensitive industries.

3V TECH is a well-known name in the segment of machinery for the chemical-pharmaceutical industry: it has been operating in this complex sector for about 50 years and has been supplying companies all over the world with standard and tailor-made solutions intended for the pharmaceutical and fine chemical sectors.

Certified Quality

For decades, Johnson-Fluiten has been supplying the rotary joints required for the operation of numerous 3V Tech machines, maintaining perfect compliance with customer technical requirements, scrupulous adherence to all standards and certifications required by outlet markets, and a constant willingness to provide no-obligation support in selecting the right component.

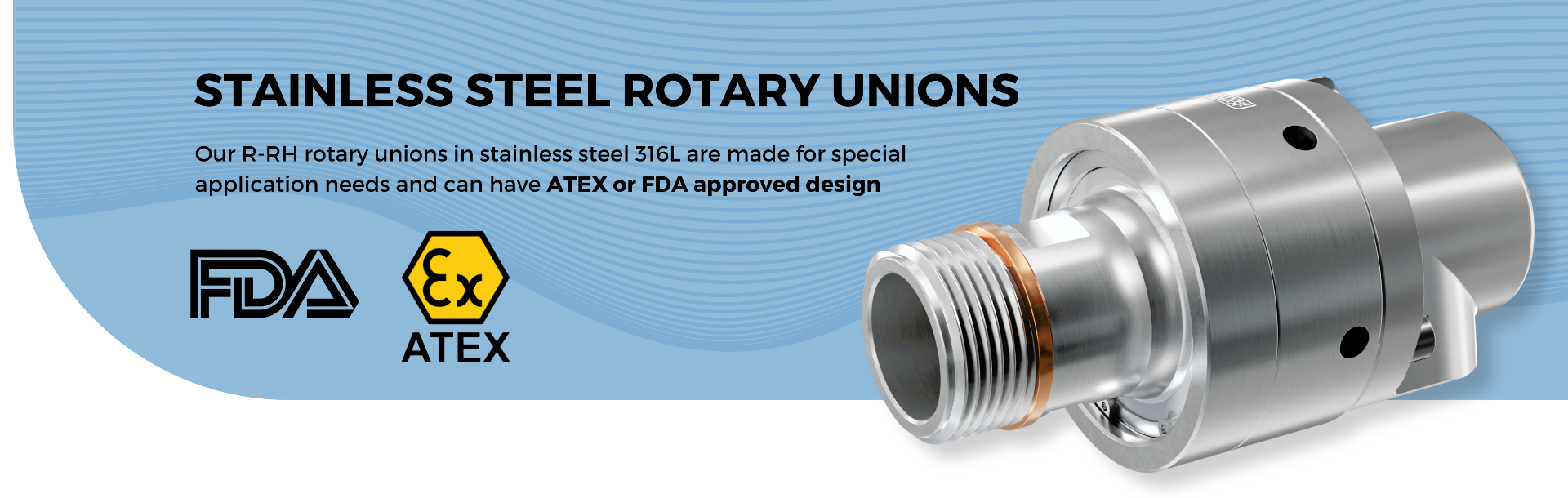

In the case of 3V Tech solutions intended for the pharmaceutical, fine chemical and agrochemical industries, while the most stringent certification requirements relate to components in contact with drugs or chemicals produced in plants, the rotary joints (which do not fall under this heading) are also required to comply with various regulations, from CE marking with the relevant certificate of conformity to the different certifications required from time to time depending on the process, local regulations and the classification of the installation area..

Frequent, for example, is the need for ATEX certification: the manufacturing process of some drugs, which at therapeutic doses and concentrations can be handled casually, in the presence of large quantities can generate potentially explosive atmospheres and/or dust that is itself explosive.

Filter-dryers

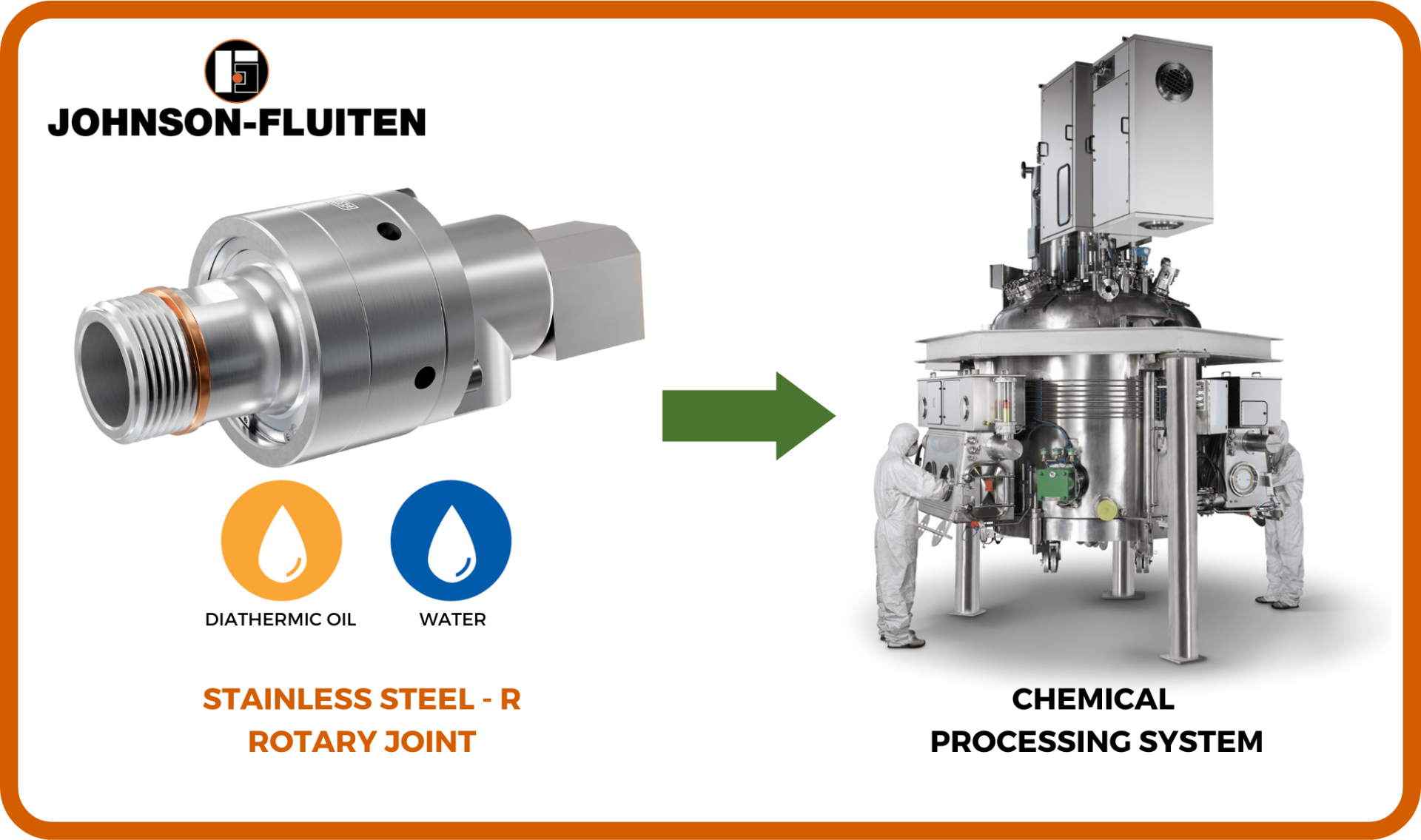

Within some machines, to speed up processes, product is moved using a rotary agitator equipped with a heating and cooling circuit. The temperature control fluid flowing in the circuit is supplied by means of a Johnson-Fluiten rotary joint.

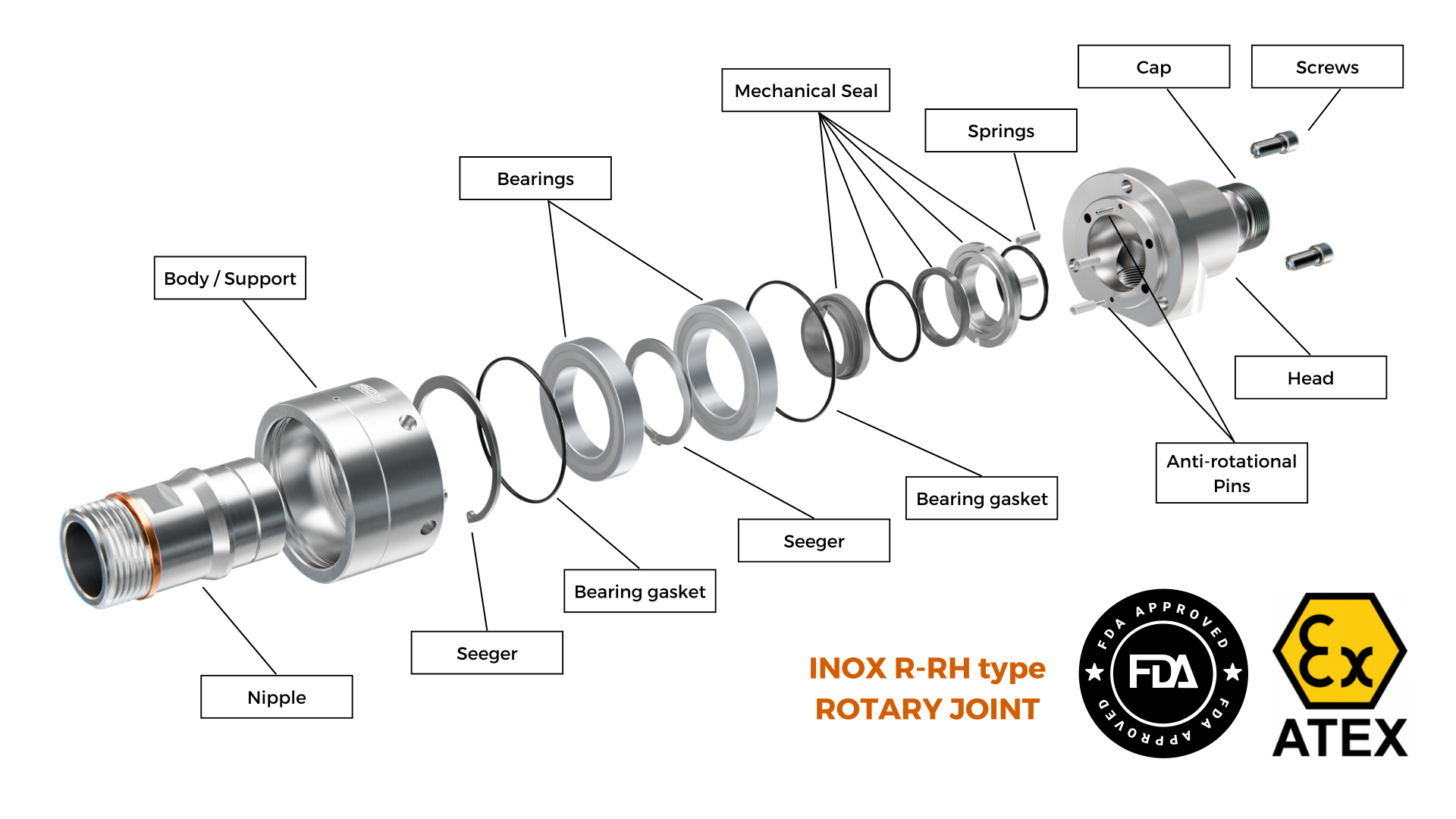

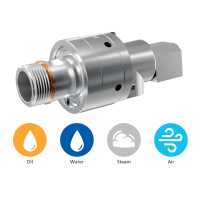

One of the advantages of Johnson-Fluiten's R-series stainless steel rotary joint is their ability to handle different types of fluids-for example, diathermic oil and water-using the same component but with different mechanical seals depending on the requirements of the application. In the case of 3V Tech machines, the fluids are mainly used for heating and cooling the agitator blades, with which various chemicals are kept agitating.

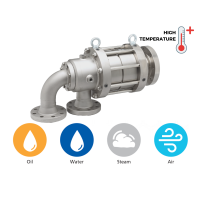

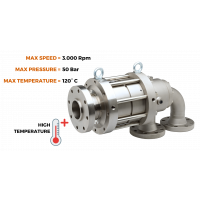

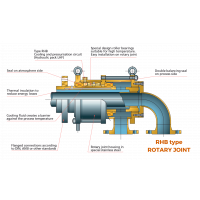

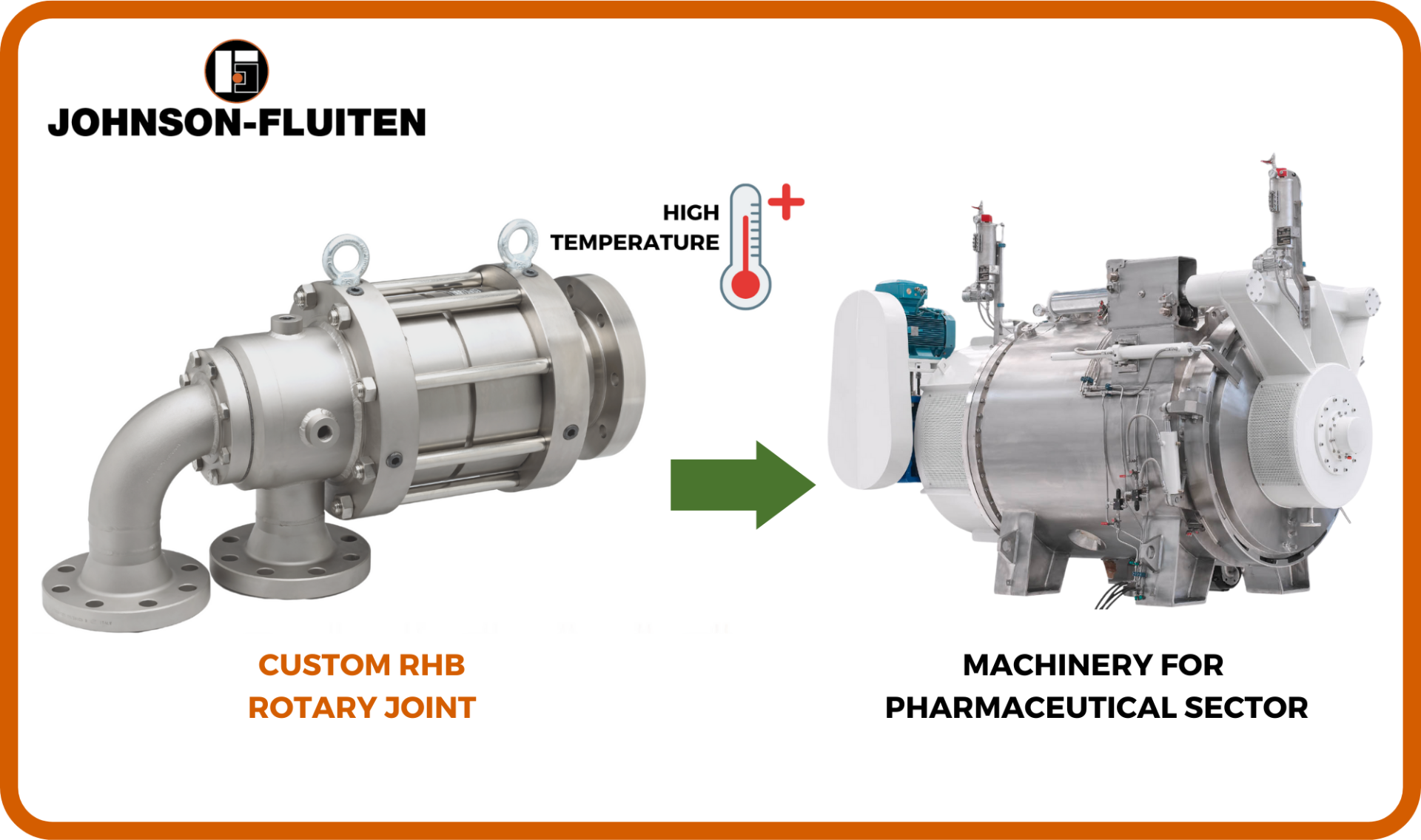

The technical characteristics of R-series rotary joints allow these components to be used in machinery for the production of active ingredients used in medicines and cosmetics. But for special or particularly heavy-duty applications with temperatures up to 400° C, Johnson-Fluiten supplies RHB couplings with special seals that enable extreme performance.

A customized solution

For a particular application, 3V Tech's designers identified the need for a three-way rotary joint: this is to allow the thermoregulation fluid (water or diathermic oil) and a second gaseous fluid (air or nitrogen) to pass inside the agitator shaft in order to perform a quick and total product emptying operation and optimize the productivity of the machinery, speeding up subsequent cleaning operations.

“Once we explained to Johnson-Fluiten's engineers what the requirements were, within a short time they carried out all the steps, from design to prototyping to testing, providing us with a three-way joint perfectly suited to the needs of this particular process”, says Scaramuzzi.

After-sales service

The filter-dryer in which the Johnson-Fluiten three-way joint is used is a sophisticated and delicate piece of machinery; therefore, Johnson-Fluiten engineers not only designed, manufactured and delivered the component but provided 3V Tech with precise instructions on how to assemble it, install it and perform the simple maintenance actions necessary to ensure reliable and consistent operation over time.

“The supporting manuals provided with the component are clear and comprehensive, but Johnson-Fluiten technicians have always been available to provide further clarification and detail by phone or hands-on demonstrations on site”, says Scaramuzzi.

Efficient processes

Johnson-Fluiten couplings have fully met the need of 3V Tech by enabling the performance of an innovative and particularly efficient process, thus contributing to the high productivity of the machinery in which they are inserted.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091