Competitiveness in the manufacturing industry is so emphasized that product quality is no longer a distinguishing point, but simply the base for staying in the market. To truly stand out, companies must go beyond flawless performance and reliability. Now more than ever, the real game-changer is service.

How can companies provide service that not only meets but exceeds customers' expectations, winning their trust and long-term loyalty? Victor Caronni, Marketing Manager at Johnson-Fluiten and Kadant Johnson Europe, shares his insights.

|

What features are crucial to competing in the manufacturing industry today?

The market today takes many things for granted; all users expect, indeed “demand,” that the product works and performs at its best: those who cannot offer these guarantees have little hope of surviving in the competitive arena. It is necessary to go beyond technical quality: the customer demands service that is up to par. And in order to provide better service, one must start with listening to his needs, analyzing his “pain ponts,” and translating this into concrete actions to address them.

Machine tools, in particular, present particularly harsh operating conditions, and Johnson-Fluiten rotary joints are capable of top performance. However, to avoid system failure, it is critical that the component assembly is correct.

As much as assembly is outside the supplier's sphere of control, and thus in theory also outside his or her responsibility, Johnson-Fluiten has every interest in having satisfied customers, which is why we have created a series of tools to optimize assistance in selection, assembly, and maintenance.

|

How do you figure out which problems need attention?

Let me give a real-life example; in machine tools, suboptimal lubro-cooling is definitely a source of inefficiency and drops in performance. In circumstances where problems occur, it is almost systematic that they turn out to be due to errors that cannot be blamed on the product. Of course, our technicians take immediate action when a customer reports malfunctions, but our interventions almost always have an unsurprising outcome: we often find problems in the way the rotary joints have been mounted.

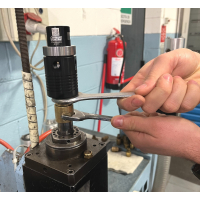

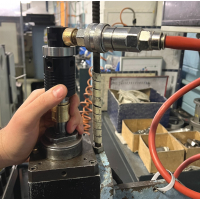

To remedy this problem, we have created a detailed 3D video with step-by-step assembly instructions, dedicated specifically to G-Series rotary joints designed for the machine tool industry.

The video visually guides technicians through the procedure, addressing complexities often overlooked in traditional manuals. For example, it illustrates the proper tools to assemble the joint and accessories to properly handle any mechanical constraints, from the use of flexible hoses to their optimal length and arrangement

A properly assembled joint maximizes process efficiency, lasts longer due to reduced mechanical wear, and cuts downtime due to the need for repairs.

What are the main needs of those involved in component maintenance and management?

For maintenance, the key requirements are speed and efficiency: repairs must be carried out quickly and return the machinery to perfect operation. Therefore, quick access to the information needed to proceed with the work is crucial.

To meet this challenge, Johnson-Fluiten has introduced a solution that is already highly appreciated by technicians, maintenance personnel, but also by purchasing managers: all rotary joints have an active QR code, laser engraved on the body of the component. This allows quick access to all the information needed to repair or replace the joint.

This tool greatly simplifies the work of maintenance workers, reducing intervention time and increasing operational efficiency since, in addition to the information, it gives the option of requesting a bid for the necessary material. Directly in the field, by cell phone, with just a few clicks. Once this is received by colleagues, the case management and delivery process is greatly simplified, and therefore very fast.

For many rotary joints, deliveries therefore occur very quickly, often less than 24 hours after confirmation, and difficult to match by most of our competitors.

|

|

What is Johnson-Fluiten's commitment to ensuring the quality of rotary joints?

The quality control aspect is crucial to maintaining our position in the market: we cannot allow defective products or products that do not meet customer expectations to leave our warehouses.

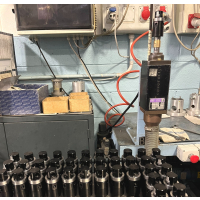

That is why every single G-series joint is individually tested before delivery, with a very strict protocol: the test is carried out on a specially designed test stand to recreate the real conditions of intensive use.

Fluid is fed into the rotary joint at a pressure of 10 bar to test the integrity of the seal, while the electrospindle spins at a speed of 10,000 rpm reproducing real operating conditions. After testing, the joint undergoes further testing with compressed air to verify the seals.

The customer who receives our product can be comfortable about the fact that it will be fully functional. WATCH THE TEST VIDEO

What other initiative is being developed to improve the customer experience?

Listening to customers and analyzing their needs is a strength of ours, which clearly must have as its logical sequel the resolution of real problems: that is why we create useful content in this regard.

Today we have talked about the creation of videos and QR code-accessible information content; but these activities are part of a larger project of developing useful and targeted content for all users of our joints, which includes articles with case histories, technical tips and guides to prevent problems in fluid handling.

And interestingly, their implementation also involves European colleagues from Kadant Johnson Europe BV. The shared goal is to develop tools and content that can be useful to the entire international network of customers and partners. Each video, technical guide or process improvement is created with the intention of creating cross-cutting value, concretely supporting operators wherever they are. In this way, the expertise gained by Johnson-Fluiten translates into real benefit for all the markets in which they operate.

In addition, with a view to improving the customer experience, we are developing an innovative project that will result in the creation of a new web platform integrated with our global business operations. This solution will enable optimized management of inquiries, even faster responses and greater completeness of the product catalog, significantly improving the service offered. At the same time, it will make it possible to streamline and speed up internal procedures, ensuring a real competitive advantage and concrete benefits for all users.

|

How does Johnson-Fluiten support customers beyond product supply?

Our goal is that when you think of Johnson-Fluiten, you immediately think of all-around quality. Both of the pre- and after-sales service that is provided by our salespeople and the technical staff when it comes to finding solutions to solve problems on special applications.

For us, selling a product is not enough. We want to provide our customers with comprehensive service that helps them reduce costs, improve efficiency, and optimize their operations.

The marketing activities we presented today are just two examples of how we strive to be closer to our customers, offering them not only high-quality components, but also practical tools and solutions for their daily work.

|

Author of the article

Victor Caronni – Marketing Manager

Victor Caronni is a Marketing Manager with extensive experience in B2B industrial marketing and technical communication.

He personally create, plans, and executes strategies, campaigns, and content for the Kadant and Johnson-Fluiten brands, overseeing every stage of the process.

He specializes in integrated digital marketing strategies that align with business objectives and deliver a direct impact on revenue.

His approach combines strategic vision with hands-on execution, ensuring that every initiative generates measurable and lasting results.

Author profile  LinkedIn

LinkedIn

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

Our goal is to work closely with our customers to develop reliable, efficient and technically advanced products that add value by improving the process and quality of the final product.

Contact us and one of our experts will be available for any of your needs!

info-jf@johnson-fluiten.com

+39.023394091

Industrial rotary unions are essential components for transferring fluids such as thermal oil, steam, and water under extreme operating conditions. These rotary joints are engineered for high-temperature and high-pressure applications in various industrial sectors, including machine tools, paper production, food and beverage processing, plastics and rubber, and chemical plants. Our rotary unions are available in single or dual flow configurations, with graphite sealing, carbon-fiber gaskets, and spheroidal cast iron bodies. Made in Italy with a focus on durability and long service life, our products reduce downtime, maintenance costs, and unscheduled machine stoppages. We offer custom rotary unions, specialized connections (flanged and threaded), and rotary unions with antimony-impregnated graphite rings for enhanced wear resistance. Technical reliability and maintenance efficiency are at the core of our product design. We provide rotary joints with low-maintenance designs, high-speed resistance (up to 500 RPM), and operating temperatures exceeding 300°C. For OEMs and end-users, we offer a wide range of spare parts for rotary unions, sealing systems, and dynamic fluid interfaces. Our services include on-site technical support, rotary joint diagnostics, predictive maintenance, spare parts replacement, system upgrades, and rapid intervention in case of rotary union failure. We also perform rotary union regeneration, refurbishment of rotating components, and full fluid handling consultancy to improve energy efficiency and process optimization. Common challenges in the field include fluid leakage, early wear, frequent breakdowns, unplanned downtime, and difficulty sourcing industrial-grade spare parts. We solve these issues through advanced rotary sealing systems, tailored fluid transmission solutions, and robust technical assistance programs. For technical teams and maintenance managers, we provide support in the selection, installation, and commissioning of rotary joints, ensuring maximum thermal efficiency and continuous plant operation. Whether you need rotary unions for food-safe environments, FDA-compliant systems, or high-performance solutions for aggressive fluids, our portfolio is designed for industrial excellence. In the B2B industrial marketing space, we offer tailored marketing strategies for mechanical companies, manufacturing exporters, and technical SMEs. Services include industrial SEO, content marketing for engineering, case history development, video tutorials, multilingual technical translations, and storytelling for mechanical brands. We help industrial manufacturers improve brand visibility, generate qualified B2B leads, and implement structured marketing plans. From LinkedIn campaigns and Google Ads to industrial newsletters and white papers, we build integrated strategies for inbound marketing, lead nurturing, and export promotion. Our marketing for machinery producers includes CRM implementation, marketing automation, email sequences, and sales funnel development. We support companies in repositioning their industrial brand, creating a strong technical tone of voice, and optimizing product pages with SEO copywriting and structured data for technical datasheets. Typical industrial marketing pain points include lack of online visibility, outdated websites, poor digital content, over-reliance on word-of-mouth, and unstructured marketing initiatives. We address these by building multilingual landing pages, content hubs, pillar pages for technical topics, and rebranding strategies aligned with international expansion goals. We work with companies aiming to strengthen their digital presence in export markets like Germany, France, and Northern Europe. Whether you are a rotating equipment manufacturer or a B2B component supplier, we deliver strategic support to boost global competitiveness, digital sales channels, and industrial lead acquisition. We also offer marketing training for technical teams, marketing audits for SMEs, and hands-on support to develop effective communication tools such as product catalogs, technical brochures, SEO-optimized blog posts, and value-driven case studies. By combining field-proven industrial experience with advanced digital strategies, we help companies in fluid handling, sealing solutions, and process optimization reach their business goals with measurable ROI. Topics we cover include: • Rotary unions for high-temperature applications • FDA rotary joints for food industry machinery • Sealing systems for rotary fluid interfaces • Marketing for mechanical engineering companies • Digital marketing strategies for industrial SMEs • Technical storytelling for B2B industries • Online lead generation for component manufacturers • Predictive maintenance and diagnostic solutions • Technical product copywriting and SEO optimization • Industrial branding and employer brand positioning • LinkedIn and Google Ads for industrial lead generation • Marketing automation for technical sales • White papers and downloadable assets for decision-makers • Export marketing strategies for international trade fairs • Landing pages and PPC campaigns for B2B conversion • Content development for engineering blogs • Catalog SEO and data-driven content hubs Our goal is to connect high-quality rotary union technology with strategic industrial marketing — turning technical excellence into business growth.