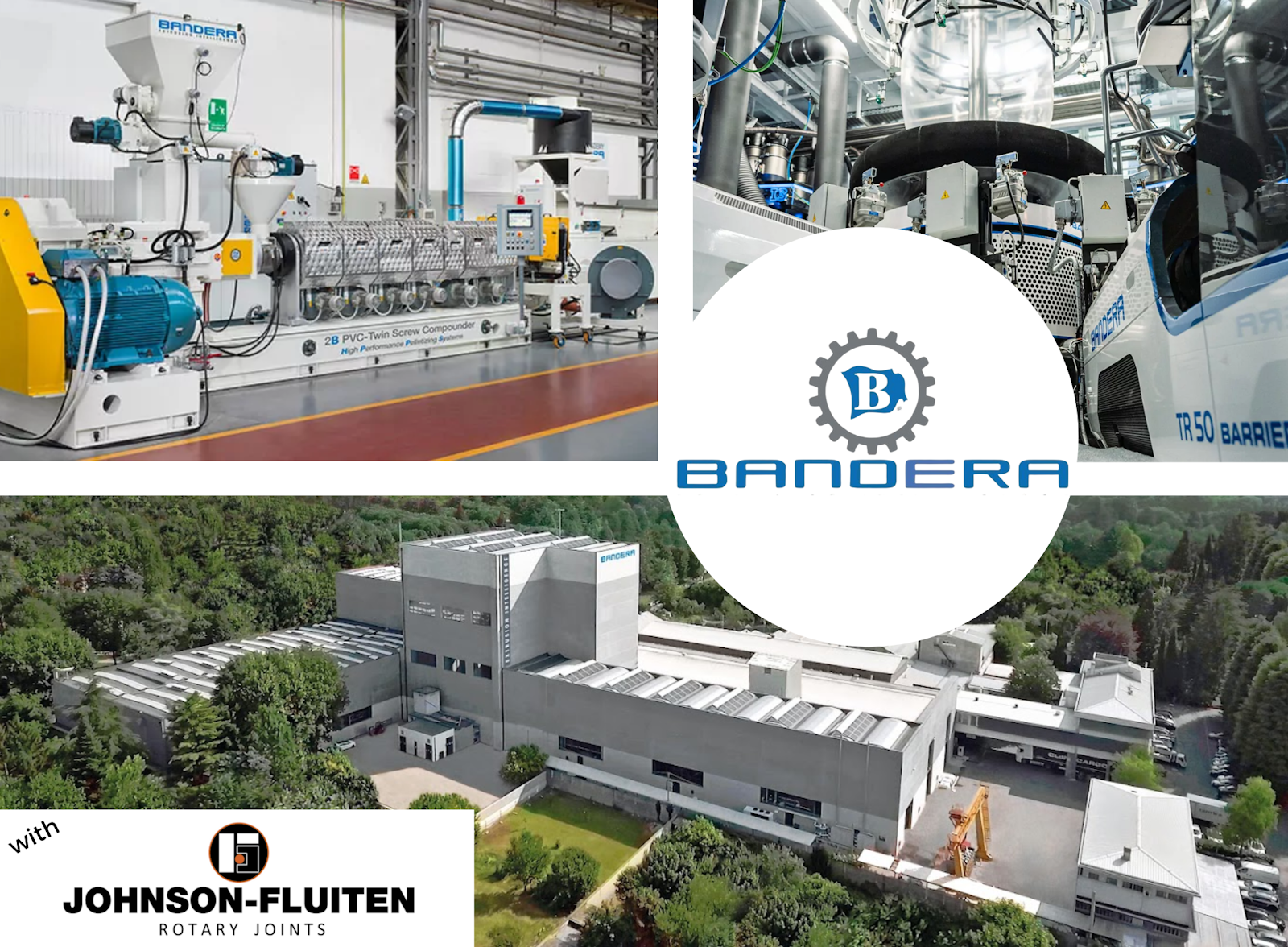

Simplified maintenance for calender systems in Luigi Bandera's machines thanks to Johnson-Fluiten rotary joints

Two companies with many things in common, from the focus on research and development to customized consultancy, as well as control over all stages of production to ensure that the proposed solutions meet the highest standards. Similarities that led Luigi Bandera to find in Johnson-Fluiten a valuable partner for the supply of components that make the production process more efficient

Costruzioni Meccaniche Luigi Bandera Spa is a leader in the plastic extrusion industry: the founder, after whom the company was named, was a pioneer in the sector, building in the immediate postwar era a screw extruder for PVC tubes and profiles that was highly innovative for the time.

From 1947 to the present, a lot of ground has been covered: in the decades since the company's official founding, the range of extrusions has expanded to include sheets alongside pipes and profiles. The introduction of blown film and sheets extruded with flathead equipment at the end of the last century led Luigi Bandera to the leading position in the plastic extrusion industry that it still maintains today.

With the recent launch of UP-CYCLING technologies, Luigi Bandera has provided an answer to the growing demand for extruded plastics recycling solutions: the company's complete systems for post-use, post-industrial and PET recycling make it possible to transform recycled materials into a high-end product with high added value, with qualitative and quantitative yields comparable to processes using traditional raw materials.

Flat-head extrusion lines

Among the many solutions offered by Luigi Bandera, flathead plants for sheet extrusion, equipped with a sturdy calender structure, available in horizontal, vertical or diagonal configurations, are of great interest.

The sheets that can be produced with these plants can be made of PET, ABS, PPMA, PP, PE, PS, ASA and SBS and find application in multiple industries: food packaging, films for furniture, transparent optical sheets for construction, lenticular molds with three-dimensional or motion effects, waterproof membranes, EVA inner layer of solar panels, and custom-made sheets for different segments of the manufacturing sector, from automotive to household appliances.

In order to bring the calanders to the correct temperature for processing each material, a heating fluid is required; this passes through a fixed pipe and is fed into the calender, which, in contrast, is in constant rotary motion. Therefore, the adoption of a rotary joint is necessary to make it possible to handle the fluid

An established partnership

Several years have passed since Luigi Rolfini, Industrial Sales Manager of Johnson-Fluiten, a supplier well known in the industry for the reliability of its solutions, suggested to Luigi Bandera the adoption of their rotary joints.

At the time, Luigi Bandera was using rotary jointss from other manufacturers, but he put the new supplier to the test to create a custom-made joint for a new series of calenders for plastic film production. Johnson-Fluiten, in addition to offering a full range of products for all needs, is distinguished by its ability to customize: in this case, too, the supplier carefully studied Luigi Bandera's needs, arriving quickly to propose a rotary joint suited to the application requirements.

Since then the relationship has been strengthened and now Johnson-Fluiten supplies Luigi Bandera with standard R-series rotary jointss available in different sizes, from the smallest size of 3/8“ to large ones up to 6”. And special solutions are also supplied with C3 seals made of Tungsten, Silicon and Viton for handling dirty water (with the presence of particles) up to 120° temperature.

Solutions for any fluid

For applications requiring heating or cooling using contaminated water, i.e., containing residual material, Johnson-Fluiten has come up with components that are simple and robust; easy to align, long-lasting even under harsh conditions, and always perfectly reliable. The RL and RHL rotary rotary jointss are special versions of the R series that, with a simpler design, a lightened structure, reduced external dimensions, and with the seal ring made of graphite (instead of stainless steel as on the R/RH rotary jointss) provide excellent performance and represent the best solution between efficiency and cost containment.

In cases where the fluid to be handled is impurity-free water or oil, Johnson-Fluiten's R-RH series rotary jointss are an ideal solution: the fluid inside them is sealed by a balanced, micro-lapped mechanical seal that ensures total absence of leakage. Reliable under all conditions, they are supported by two widely spaced ball bearings and are generally used in high-speed applications requiring low drive torque.

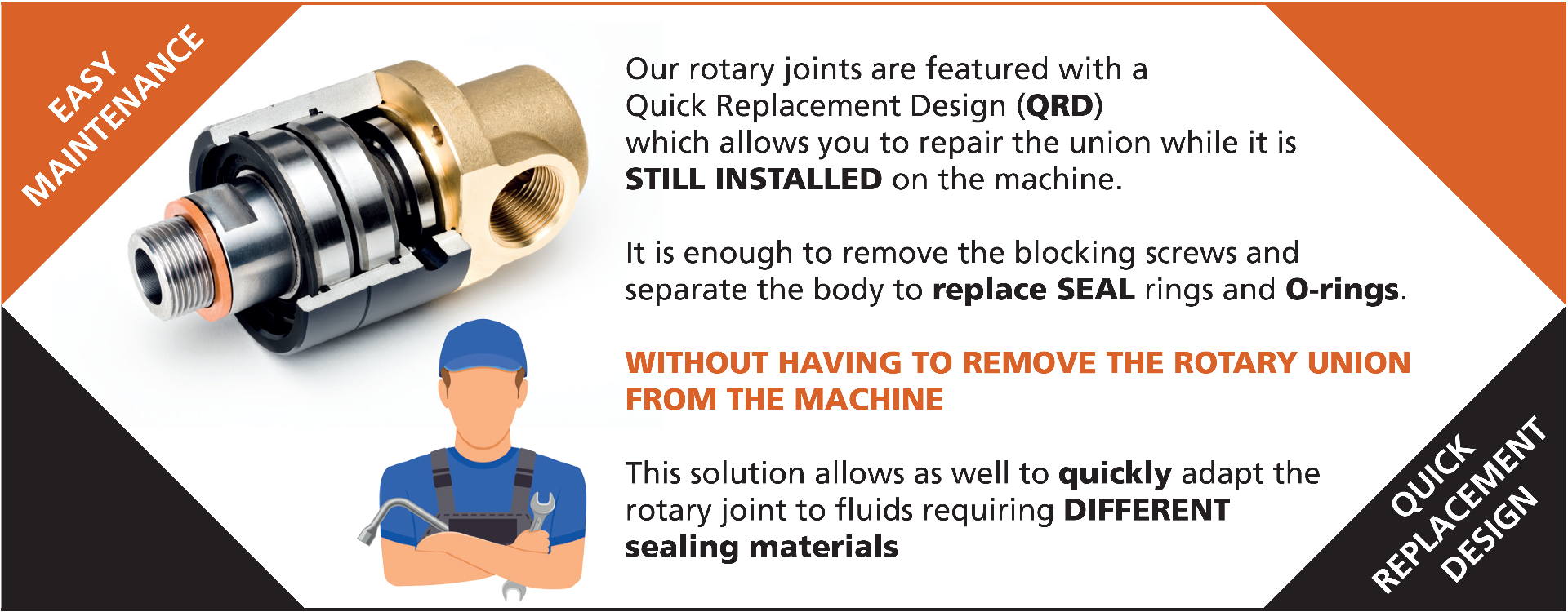

Quick and easy maintenance

One of the features of Johnson-Fluiten rotary joints most appreciated by Luigi Bandera is the ease of maintenance. As Paolo Crespi, the company's Technology Buyer, explains:

“The biggest advantages that Johnson-Fluiten rotary joints have over their competitors are that you can service their joint without having to disassemble them from the cylinder, using their repair kit”.

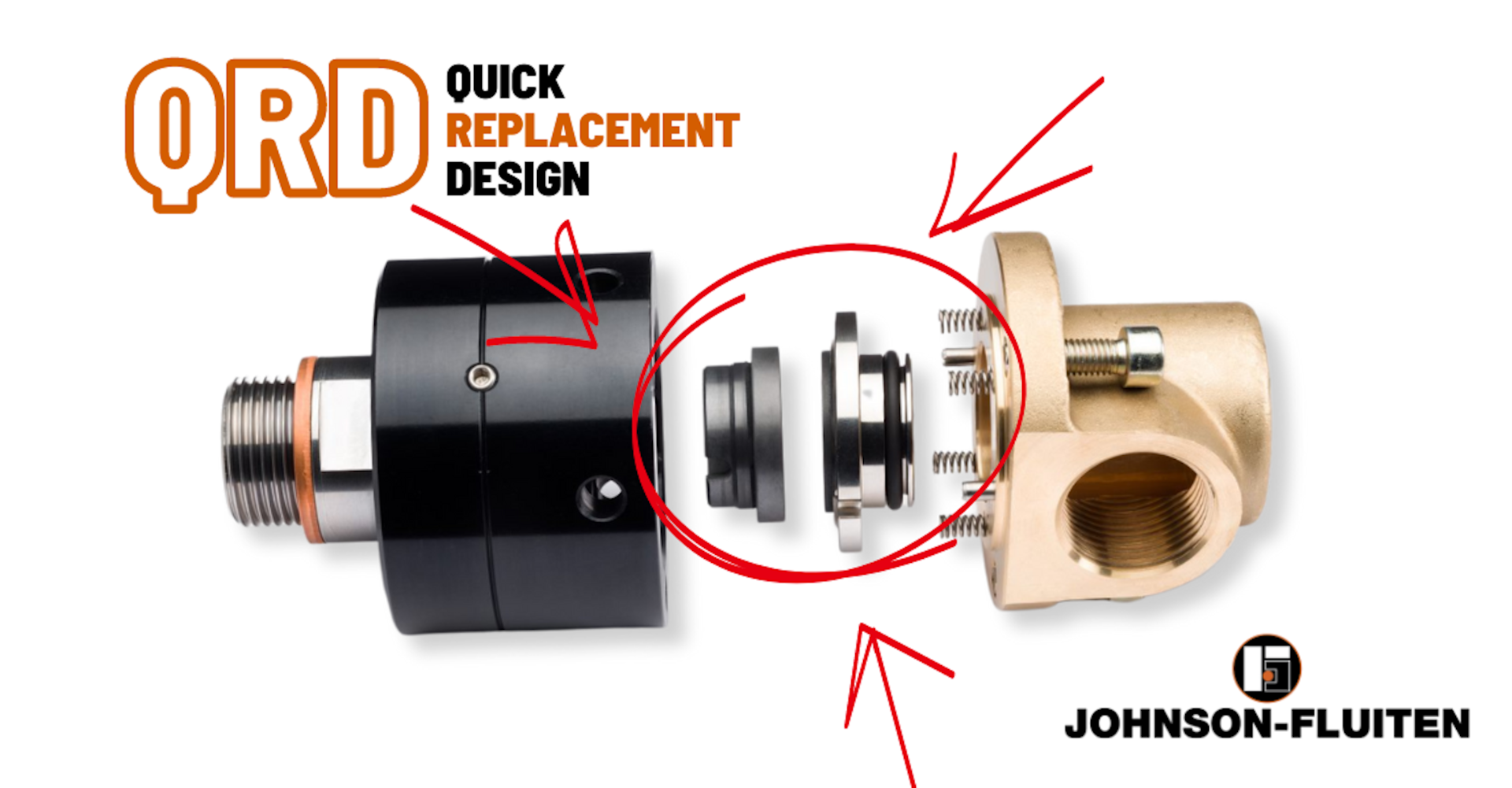

All R-series rotary joints feature their unique quick-change (QRD) design. They are designed to allow intervention on the joint while it is still installed on the machine.

For a company like Luigi Bandera, which exports a significant portion of its production, the ability to perform guided maintenance even remotely, with a few simple instructions and the handy maintenance kit provided by Johnson-Fluiten, is of considerable benefit.

A great partner

In addition to quick and easy maintenance, Paolo Crespi also speaks favorably about several other sides of the relationship with Johnson-Fluiten:

“The aspects we value most are the breadth of the range, the quality of the products, the punctuality of delivery, and the pre- and after-sales service”, explains Crespi, who concludes:

“We are completely satisfied with Johnson-Fluiten in every respect, and will certainly continue to use their rotary joints for future projects”.

Author of the article

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091