High-performance sugar industry: the Babbini case study showcases the excellence of Johnson-Fluiten

For over a decade, Babbini has been using Johnson-Fluiten rotary joints in its presses: solutions that have proven to be reliable, flexible, easy to maintain, and supported by an ever-present technical service. A relationship of trust that has contributed to the reputation for excellence of the machinery manufactured by this historic Italian manufacturer.

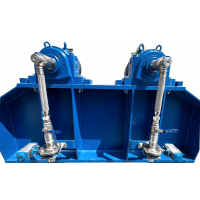

Founded over 160 years ago, Babbini specializes in the design and construction of dehydrating presses for the sugar industry. Its high-efficiency solutions, based on counter-rotating twin screw systems and hollow shafts, are now used worldwide to optimize liquid-solid separation processes. Babbini machines, often customized to customer requirements, are distinguished by their high operational efficiency, even under harsh conditions.

Attention to components has always been an integral part of Babbini's design philosophy. Since the 1990s, the company had been using Johnson rotary joints, which at the time were manufactured by the US company that, following a joint venture with Fluiten, became Johnson-Fluiten. After a brief period in which Babbini tested an alternative proposed by one of its major European competitors, attracted by more favorable commercial conditions, the choice fell once again on Johnson-Fluiten. Some end customers had in fact detected unacceptable leaks, confirming how crucial it is to rely on a partner capable of guaranteeing continuous performance and high-quality seals over time.

“We have seen that saving on critical components can compromise the overall performance of the machine and customer satisfaction. With Johnson-Fluiten, we have regained operational peace of mind and a much higher perceived quality, even among those who use our systems,”said Giulio Cangini, Operations Manager at Babbini.

Performance under pressure: the rotating heart of Babbini presses

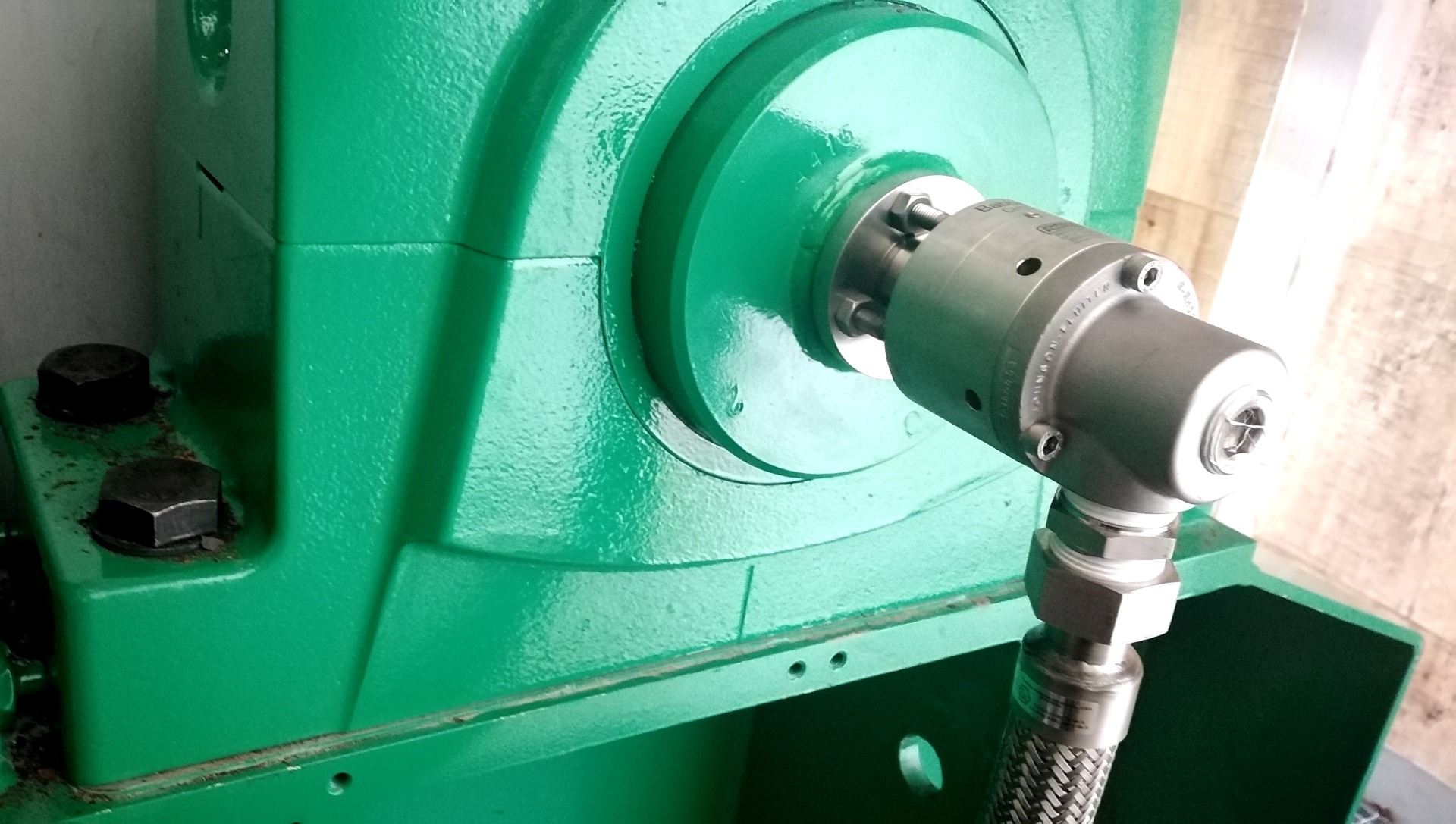

Johnson-Fluiten rotary joints are used on all Babbini presses with hollow shafts, which are essential for the passage of washing liquid inside the system. Water at 50°C and 3 bar pressure is conveyed through the joints in the rotating shaft to ensure constant cleaning of the internal holes. If the rotary joint leaks, the effectiveness of the washing is reduced, the holes risk becoming clogged, and the machine operates as a blind shaft press, reducing the amount of dry matter extracted for the same footprint. In practice, the performance of a lower-end machine is delivered, despite having invested in a more advanced solution.

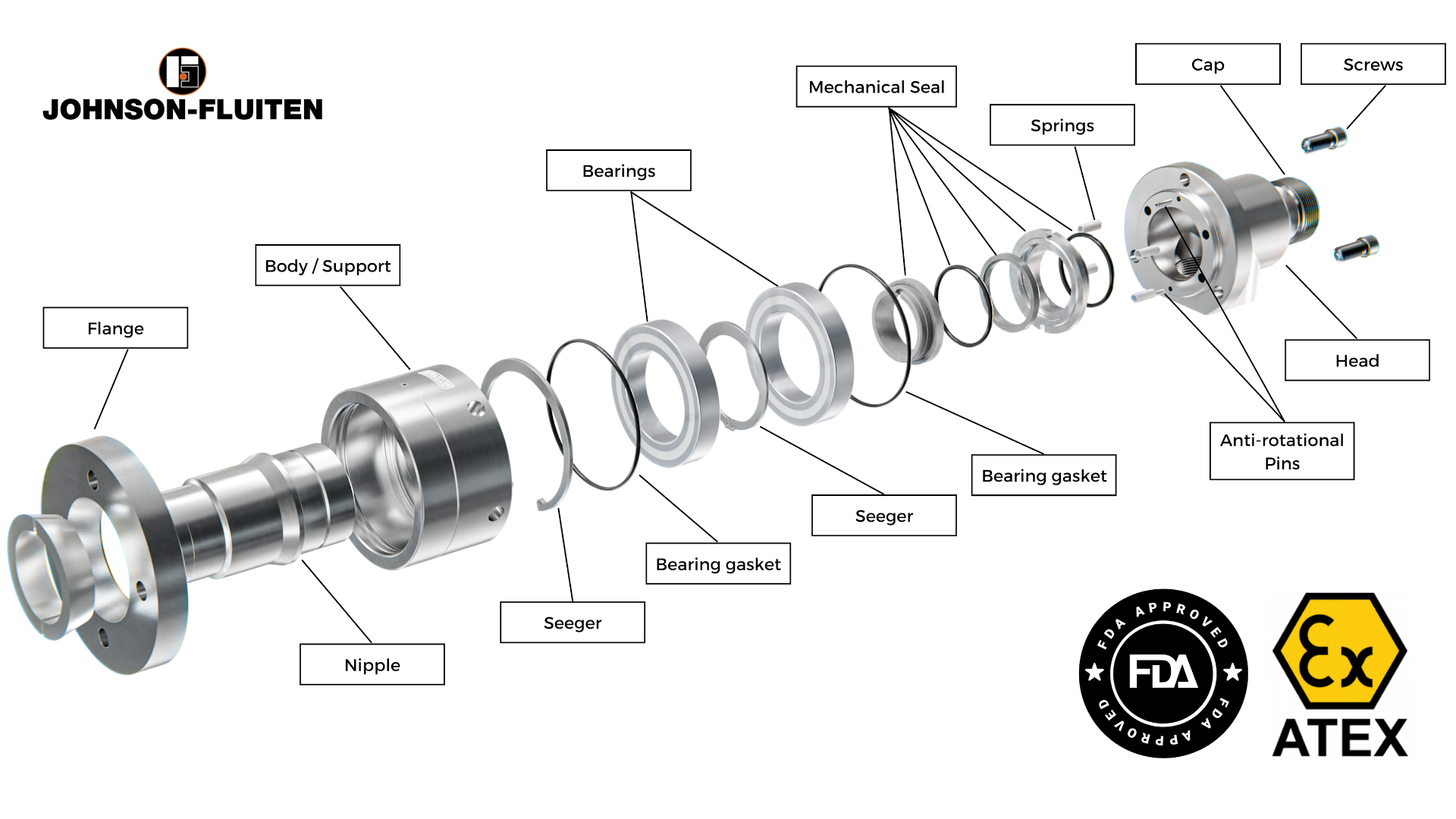

To ensure efficiency and reliability, Babbini has adopted Johnson-Fluiten's R series stainless steel rotary joints in 1¼“ and 2” sizes: joints designed to guarantee high and long-lasting performance. Even after very intense production campaigns, typical of the sugar industry, which take place from August to December (with possible extension until March), during which the presses operate 24/7, performance remains within optimal parameters, limiting the need for extraordinary maintenance.

And when maintenance is required, it is extremely simple: thanks to the characteristic design of Johnson-Fluiten rotary unions, mechanical seals can be replaced quickly without removing the entire component from the machine.

Customized solutions, even in difficult conditions

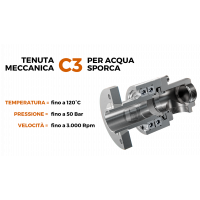

Although the use of clean water is recommended in these machines, we are aware that this condition cannot always be guaranteed. For systems that use recycled water or water containing solid particles, Johnson-Fluiten offers a configuration with a mechanical seal designed for liquids with contaminants. C3 seals are designed to operate with unfiltered water and are made of tungsten carbide against silicon carbide, while the secondary seals are made of Viton.

“For customers with production processes that involve water that is not perfectly clean, we offer versions with seals and materials suitable for more demanding conditions. This approach allows us to guarantee the reliability of the system even when conditions in the field are less than ideal,” explains Manuel Lorenzoni, Technical Manager at Babbini.

A significant example concerns an American customer who complained of frequent failures caused by sand in the water. In response, Johnson-Fluiten designed a variant of the rotary union with a duplex steel body, which is more resistant to abrasion than ordinary AISI 316. This tailor-made solution effectively solved the problem.

Cristina Locatelli, Sales Manager at Babbini, notes: “Not all of our customers have appropriate treatment systems or follow strict filtration protocols: for this reason, we offer solutions that can also work with water from previous processes, containing contaminants and suspended particles.”

A bond built over time, now strengthened by Babbini joining the Kadant group

The relationship between Babbini and Johnson-Fluiten has grown stronger over time thanks to shared values: quality, reliability, and attention to application. The possibility of choosing custom seals based on the fluids, the availability of stainless steel versions, and international certifications, such as FDA, make these couplings ideal for the food industry as well.

“With Johnson-Fluiten, we can be sure that even in the event of wear, we can quickly return to full operation. The seals can be replaced in a matter of minutes and technical assistance is always quick and effective,” explains Lorenzoni.

Reliability that is renewed season after season. And today, confirming a strategic synergy that looks to the future, Babbini has officially joined the Kadant group, further strengthening its ties with Johnson-Fluiten and an ecosystem of leading companies in the industrial sector.

Author of the article

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091

+39.023394091