kadant

-

The acquisition of Dynamic Sealing Technologies Inc. (DSTI) by Kadant Inc. marks a strategic shift for the European rotary joint industry. Below, different professionals explain what will change for customers, sectors, and technologies. Solutions for complex applications Sam Burvee

-

Categories: News IT

L’acquisizione di Dynamic Sealing Technologies Inc. (DSTI) da parte del gruppo Kadant segna un passaggio strategico per l’industria europea dei giunti rotanti. Tre professionisti raccontano cosa cambia per i clienti, i settori e le tecnologie. Soluzioni per applicazioni complesse Sam Burvee &

-

For over a decade, Babbini has been using Johnson-Fluiten rotary joints in its presses: solutions that have proven to be reliable, flexible, easy to maintain, and supported by an ever-present technical service. A relationship of trust that has contributed to the reputation for excellence of the machinery manufactured by this historic Italian manufacturer. Founded over 160 years ago, Babbini specializes in the design and construction of dehydrating presses for the sugar industry. Its high-efficiency solutions, based on counter-rotating twin screw systems and hollow shafts, are now used worldwide to optimize liquid-solid separation processes. Babbini machines, often customized to customer requirements, are distinguished by their high operational efficiency, even under harsh conditions. Attention to components

-

Competitiveness in the manufacturing industry is so emphasized that product quality is no longer a distinguishing point, but simply the base for staying in the market. To truly stand out, companies must go beyond flawless performance and reliability. Now more than ever, the real game-changer is service. How can companies provide service that not only meets but exceeds customers' expectations, winning their trust and long-term loyalty? Victor Caronni, Marketing Manager at Johnson-Fluiten and Kadant Johnson Europe, shares his insights. What features are crucial to competing in the manufacturing industry today?

-

In the corrugated manufacturing industry, steam management in roller heating processes is essential to ensure efficiency and quality of the final product. However, many companies face persistent problems related to steam leaks and frequent maintenance of rotary joints, resulting in high costs and operational risks. A case study: Steam Leaks and Inefficient Maintenance in Corrugators A corrugated board manufacturer in the Midwestern United States experienced continuous steam leaks due to a recurring error during maintenance of CorrPro rotary joints. The maintenance crew unintentionally damaged the cup seal during assembly, compromising the integrity of the system and leading to steam leakage. Faced with constant repair work, which included piston and seal replacement, the maintenance team decided to turn to Kadant Johnson for a more reliable and sustainable solution.

-

CFT Group, a leading player in the food industry machinery business, offers state-of-the-art solutions; equipment and complete production lines, manufactured in its Parma facilities, are implemented in companies all over the world. Reliable and consistent operation is aided by careful design, flawless service and, of course, the choice of premium materials and components.This is why CFT Group's partner for rotary joints is Johnson-Fluiten. For 80 years, CFT Group, a company based in Parma with customers around the world, has been producing solutions for food and beverage processing and packaging. Since 2021, the company has been part of ATS Corporation, a world leader in industrial automation: the synergy with this large company allows it

-

High-speed paper machines require precise and reliable heat transfer control to ensure uniform drying of the paper product. The PT2X™ rotary joint, exclusively distributed by Johnson-Fluiten for the Italian market, offers a cutting-edge solution to enhance efficiency in the paper production sector. Discover how PT2X™ revolutionizes production in modern paper mills! Advantages of the PT2X™ Rotary Joint 1- Extreme Reliability: Designed to operate seamlessly even under the extreme conditions of modern paper machines, the PT2X™ ensures continuous performance, reducing downtime. 2 - Balanced Seal: This feature evenly distrib

-

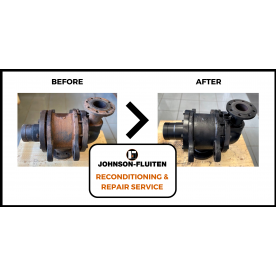

As good as new. Our rotary joint reconditioning service gives the product perfect functionality "as if it had just left the factory". We are so confident in the result that we guarantee it. All mechanical components have a 'life cycle' and when they are used in particularly heavy-duty applications, for parts exposed to normal wear and tear, it is necessary to carry out some checks and professional maintenance so that the system always works at its best. Let's take one of our customers as an example who treats animal waste (or also called 'rendering') with its plants. Treating slaughterhouse waste such as bones, blood, feathers, carcasses, leather, and turning them into bone and