How to Remove Steam Leaks in Corrugators with CorrPro® Cartridge Upgrade Kit

In the corrugated manufacturing industry, steam management in roller heating processes is essential to ensure efficiency and quality of the final product. However, many companies face persistent problems related to steam leaks and frequent maintenance of rotary joints, resulting in high costs and operational risks.

A case study: Steam Leaks and Inefficient Maintenance in Corrugators

A corrugated board manufacturer in the Midwestern United States experienced continuous steam leaks due to a recurring error during maintenance of CorrPro rotary joints. The maintenance crew unintentionally damaged the cup seal during assembly, compromising the integrity of the system and leading to steam leakage.

Faced with constant repair work, which included piston and seal replacement, the maintenance team decided to turn to Kadant Johnson for a more reliable and sustainable solution.

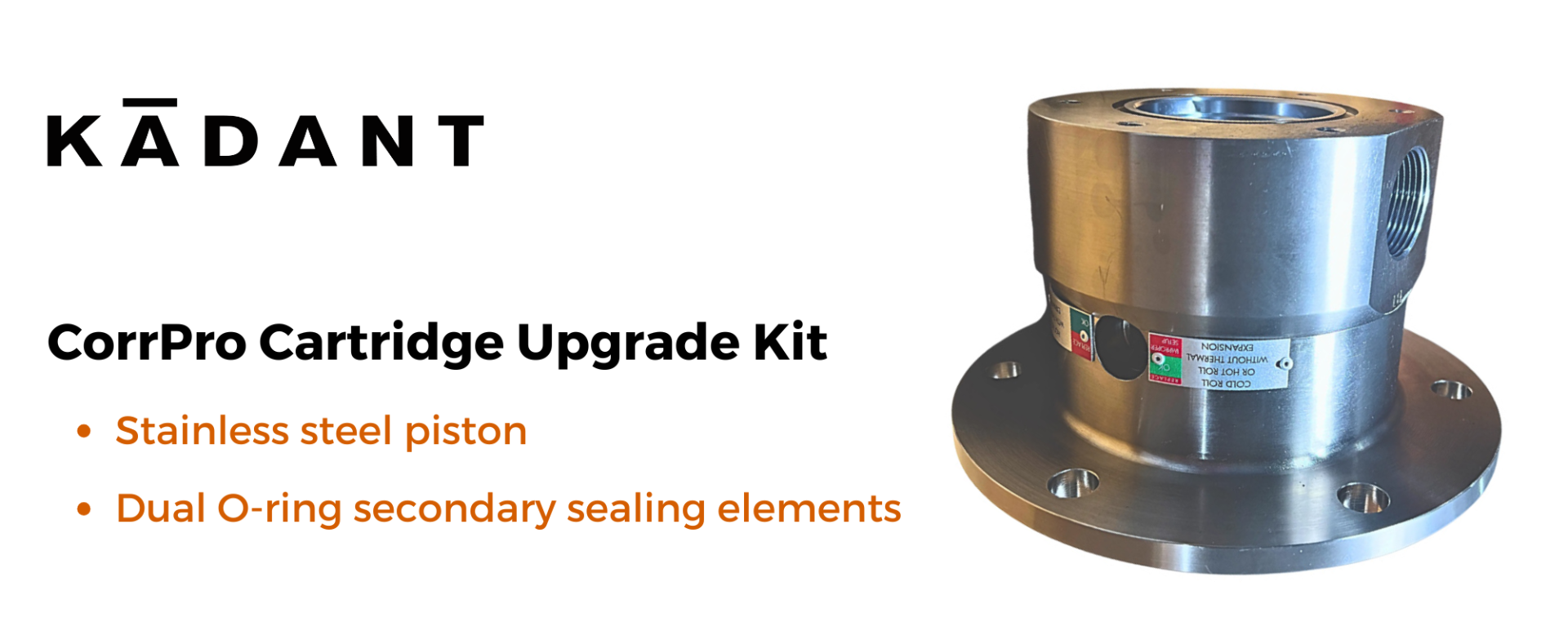

The Solution: CorrPro Cartridge Upgrade Kit

To eliminate assembly errors and reduce the impact of thermal cycling, Kadant Johnson proposed the CorrPro rotary joint upgrade kit. This kit is designed to simplify the maintenance process and improve operational reliability by:

-

Stainless steel piston: prevents deterioration caused by steam and provides longer service life than ductile iron.

-

Secondary O-ring seals: facilitate installation and increase resistance to thermal cycling.

-

Preassembled design: enables quick and error-free installation.

-

Direct compatibility: immediate upgrade for existing CorrPro rotary joints, no structural changes required.

-

Resistance up to 13.8 bar: perfectly in line with typical corrugator operating conditions.

The Results: Greater Efficiency and Lower Maintenance Costs

After installing the CorrPro Cartridge Upgrade Kit, the manufacturer reported immediate benefits:

-

Elimination of steam losses, improving energy efficiency and reducing steam consumption.

-

Reduced maintenance time and costs due to easy installation and longer component life.

-

Increased plant reliability, with more effective predictive maintenance and fewer unexpected interventions.

-

Increased operational safety, avoiding steam spills that can compromise the working environment

Why Choose Johnson-Fluiten for Fluid Management in Corrugators?

Johnson-Fluiten, a partner of the Kadant Group, specializes in providing advanced industrial fluid management solutions with a focus on rotary joint reliability and reduced maintenance costs.

If you would like to optimize steam management in your corrugated board plant and reduce maintenance costs, contact us for a personalized consultation.

Discover our solutions for a more efficient and sustainable plant!

Author of the article

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091