Meet the challenges of high temperatures with a simple component but designed to last

In the chemical, pharmaceutical, plastics and printing industries, applications requiring the use of high-temperature diathermic oil are becoming increasingly common.

But how to ensure safety, operational continuity and low maintenance requirements?

The answer lies in choosing the right rotary joint.

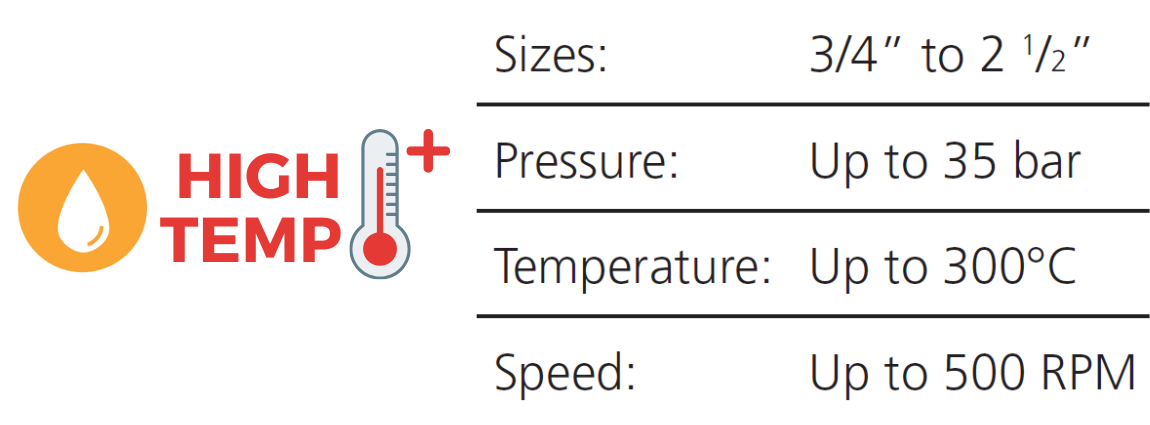

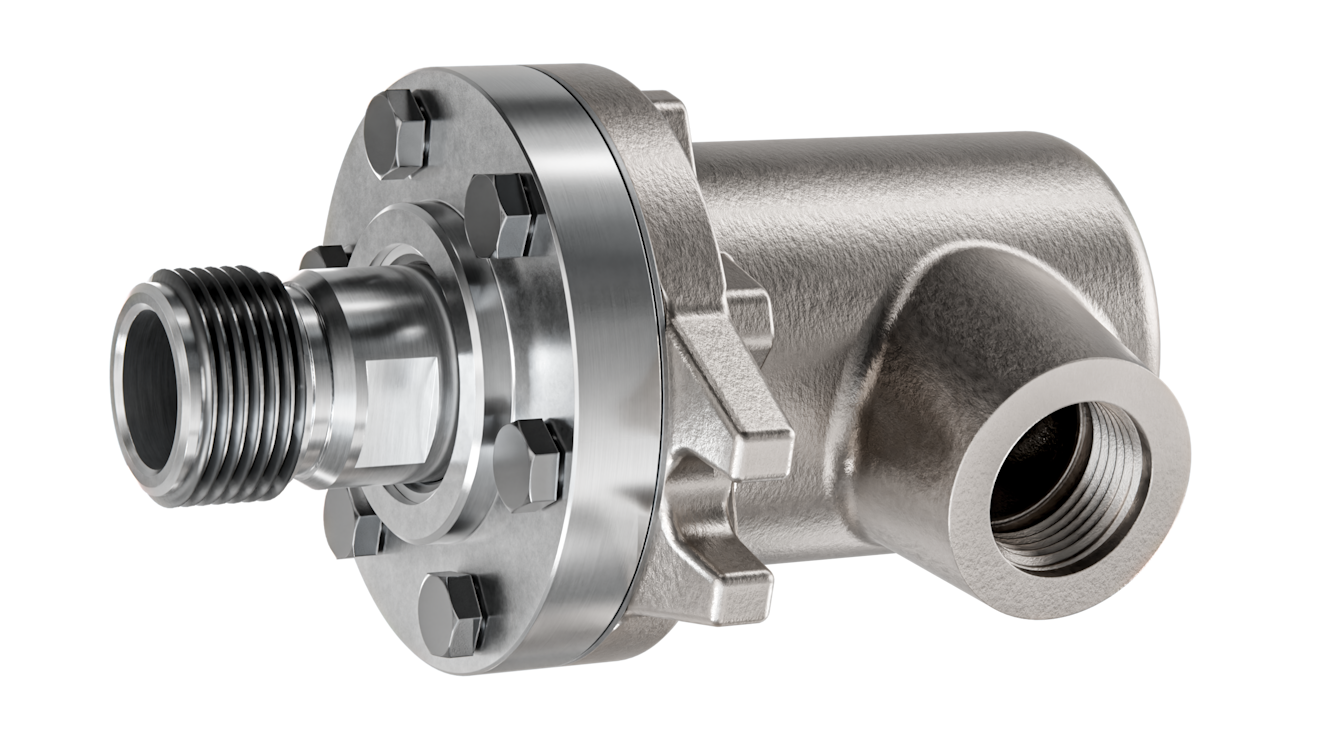

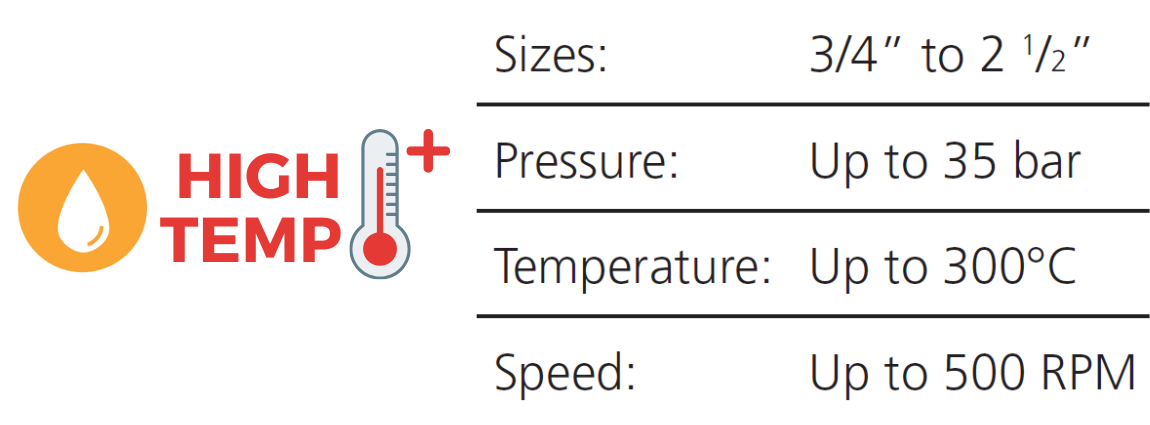

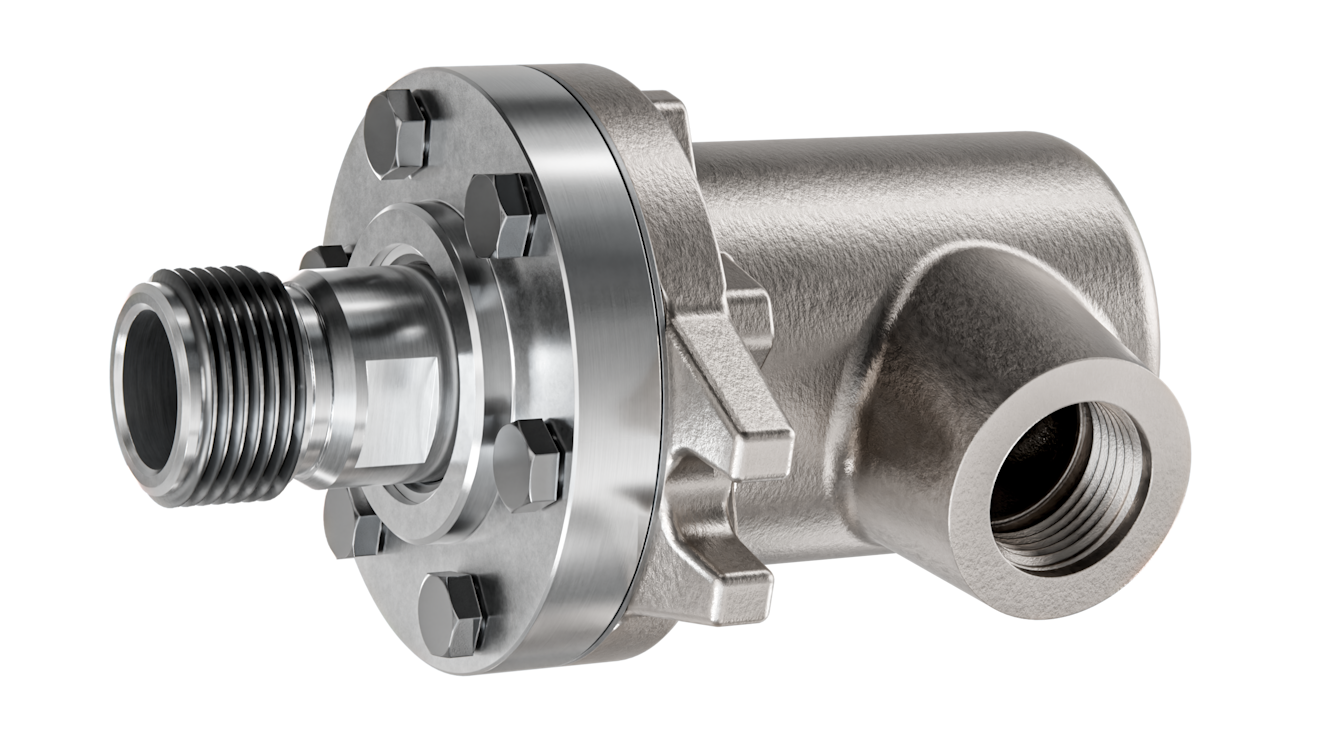

The Z-series rotary joint was developed precisely to meet these critical needs. Thanks to its design and high-quality materials, it is a reliable, efficient and durable solution even under extreme conditions. The Z rotary joint is distinguished by its thermal and mechanical resistance, making it ideal for applications with diathermic oil up to 300°C and a maximum rotational speed of 500 rpm.

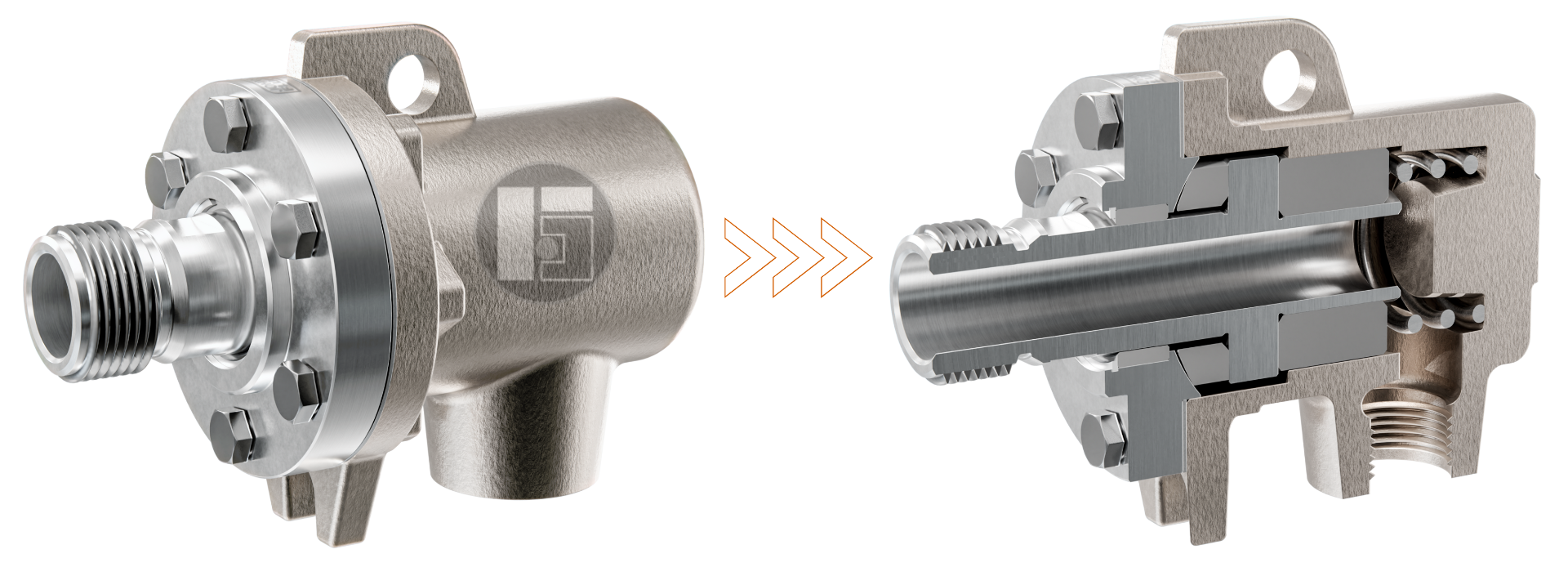

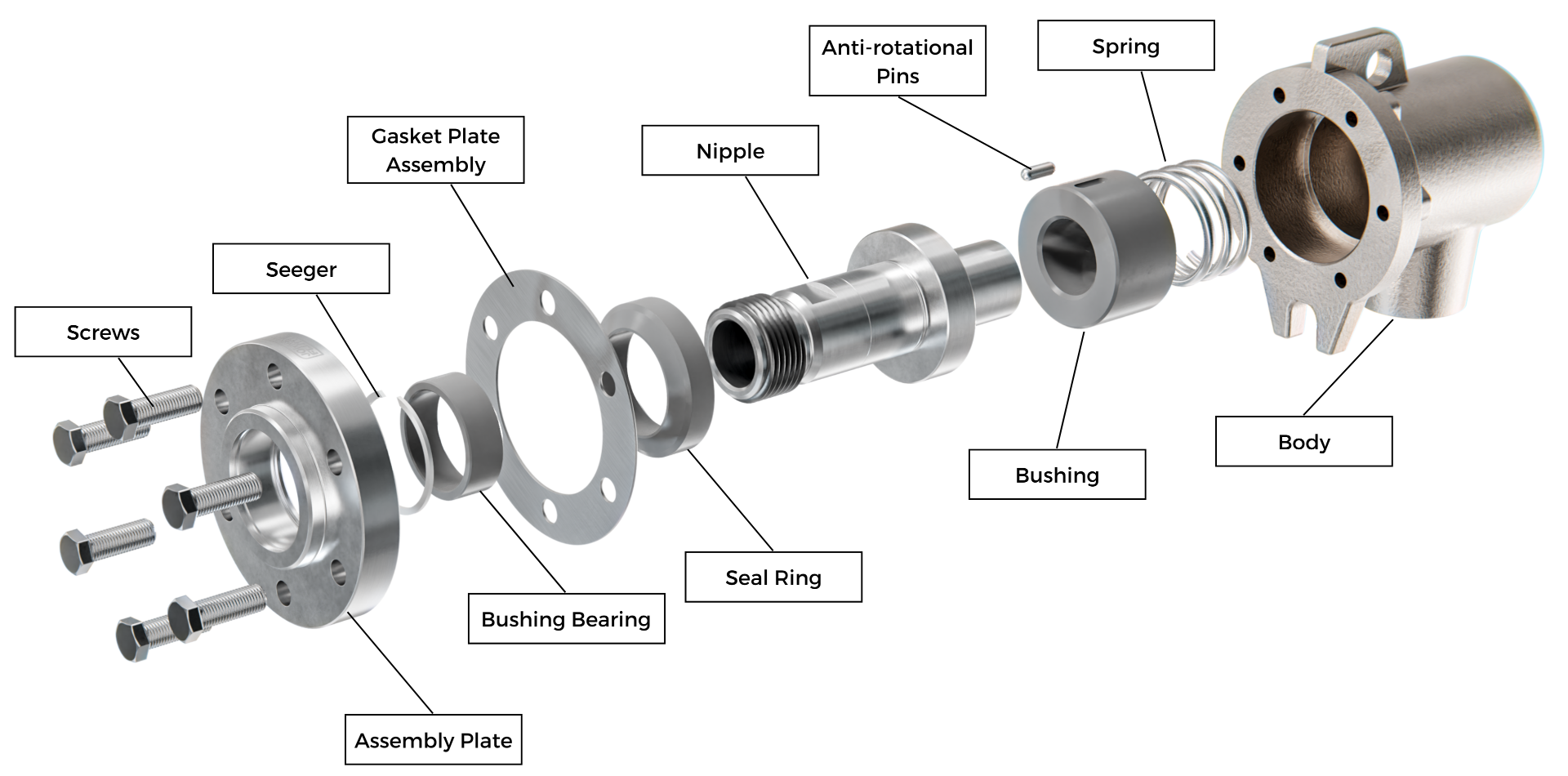

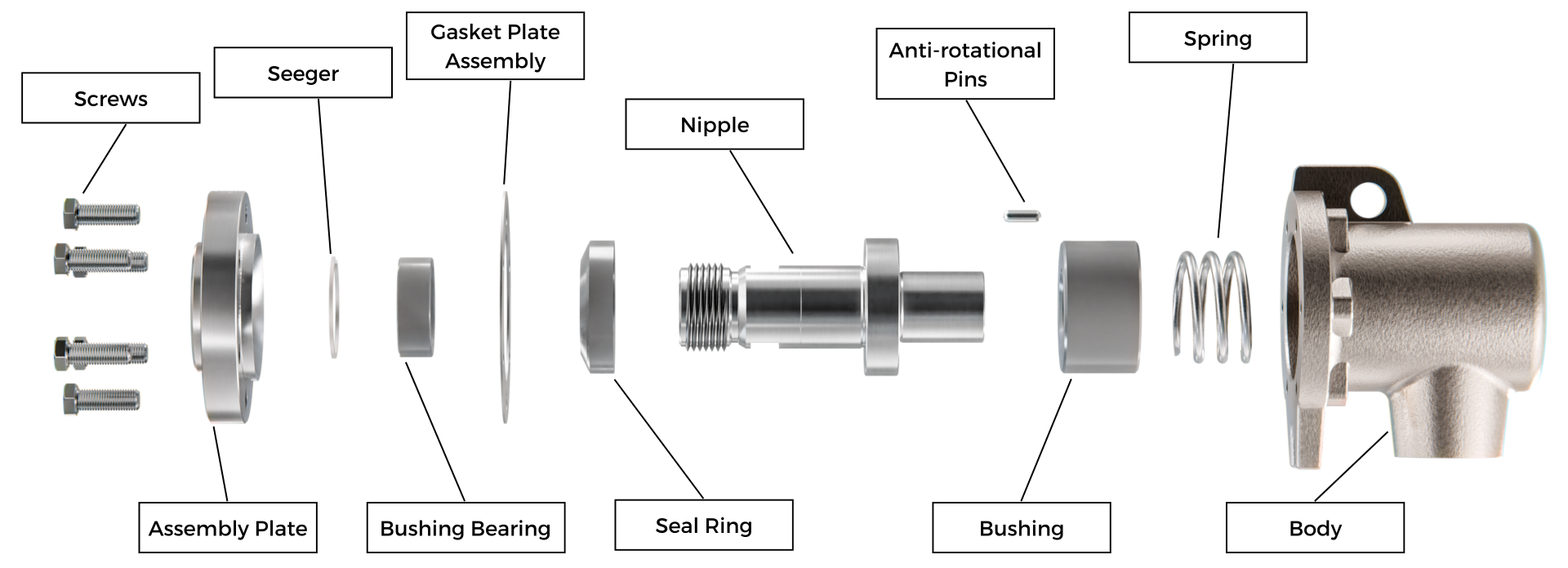

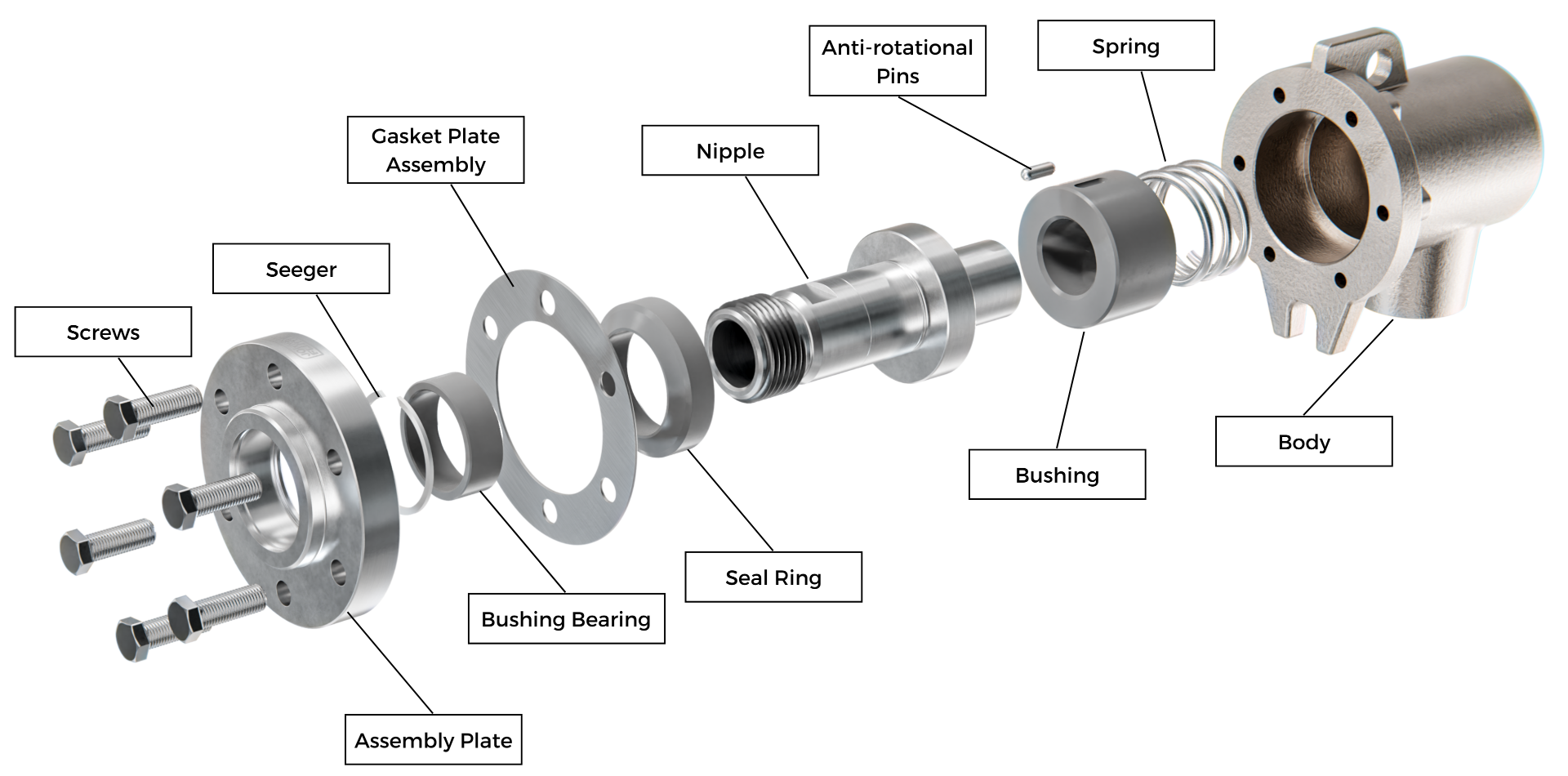

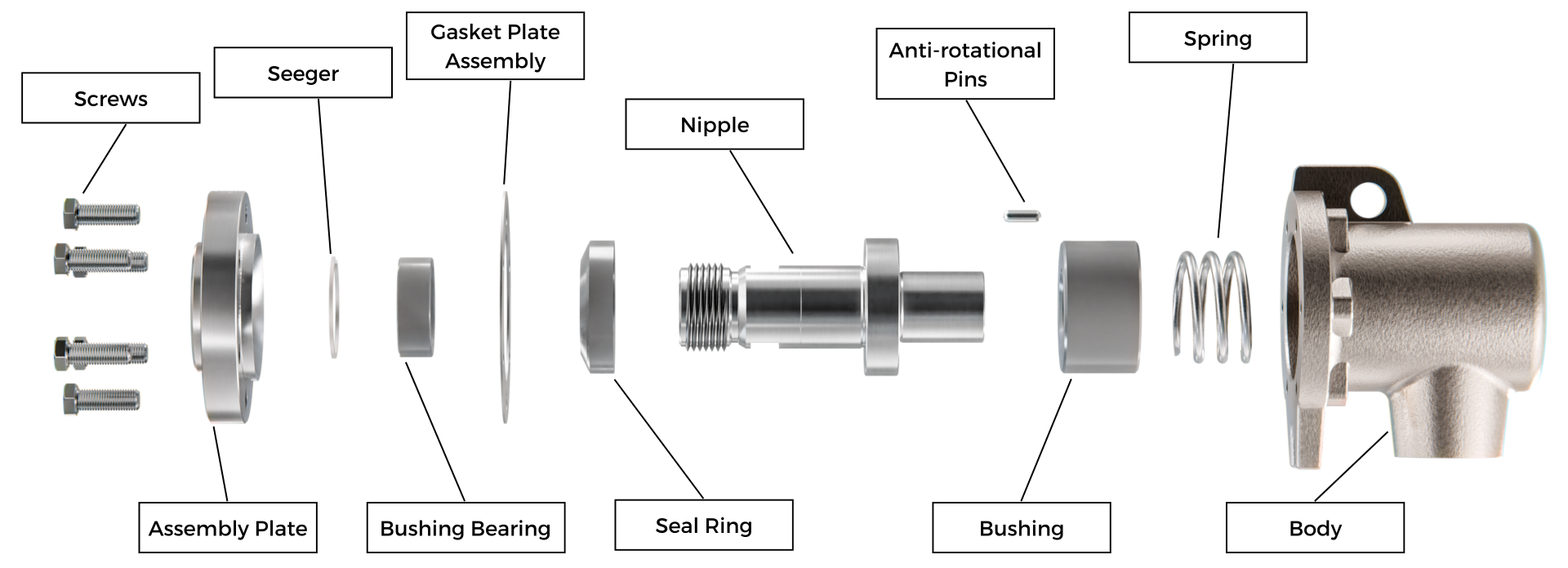

What our Z rotary joint looks like

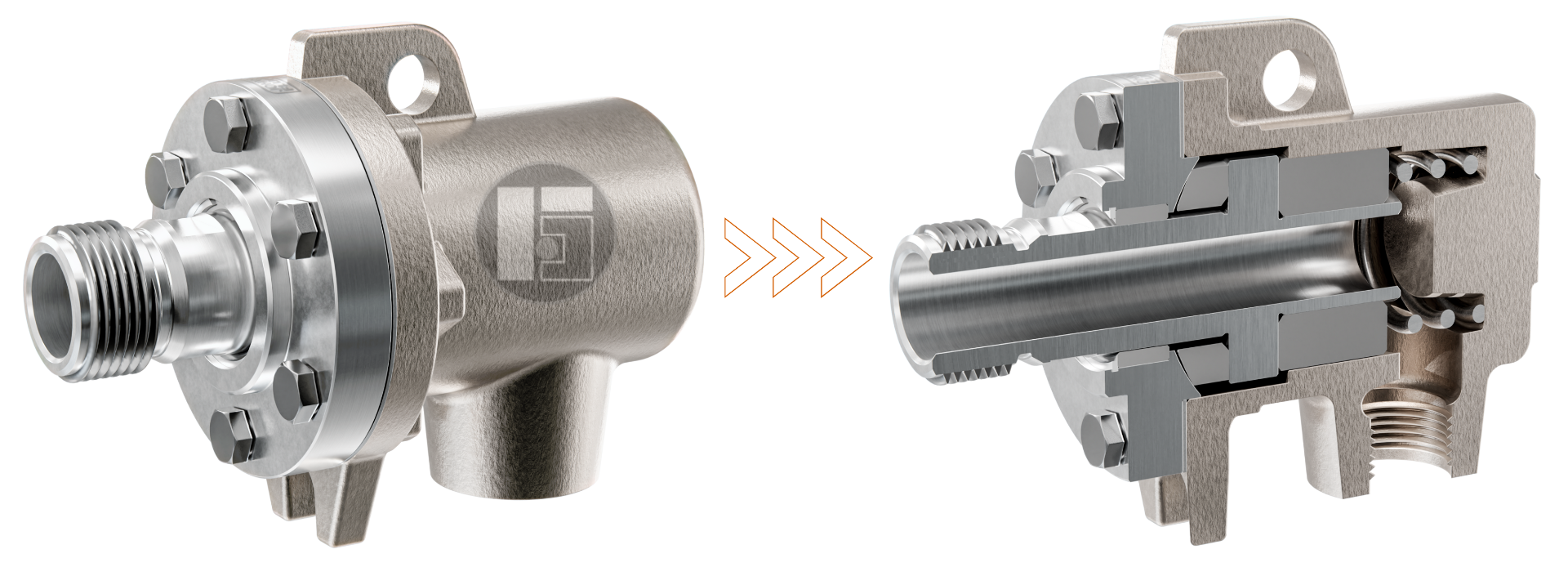

- Cast iron body: ensures strength and durability even in harsh industrial environments.

- Antimony-impregnated graphite seal ring: ensures a perfect seal even at high temperatures and pressures.

- Graphite inner bushings: minimize wear and ensure smooth operation over time.

- Compressed carbon fiber gasket: high sealing and thermal efficiency.

Available configurations:

- Single passage

- Double pass with rotating siphon

- Double passage with fixed siphon

Sizes available:

(nominal rotor diameter)

- - 19 mm or 3/4”

- - 25 mm or 1”

- - 31 mm or 1 ¼”

- - 38 mm or 1 ½”

- - 50 mm or 2”

- - 64 mm or 2 ½”

Connections for every need:

- Right or left hand threads (BSP ISO228 standard)

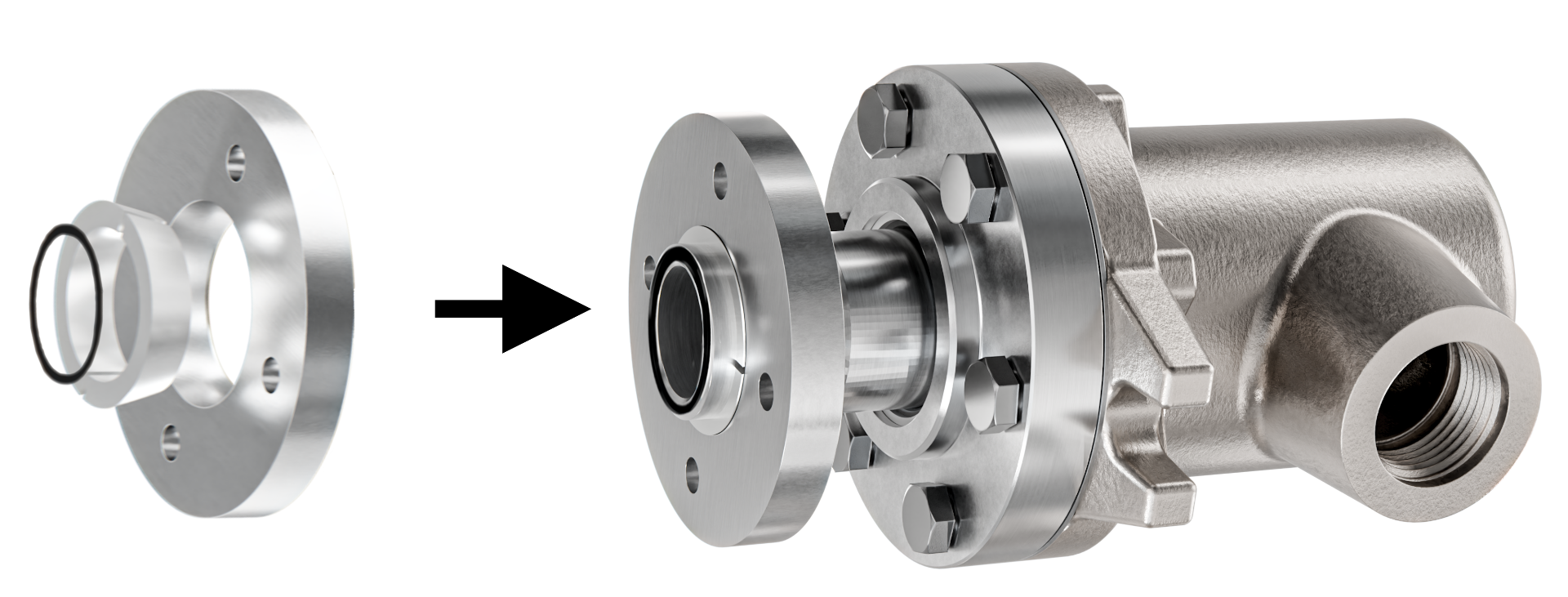

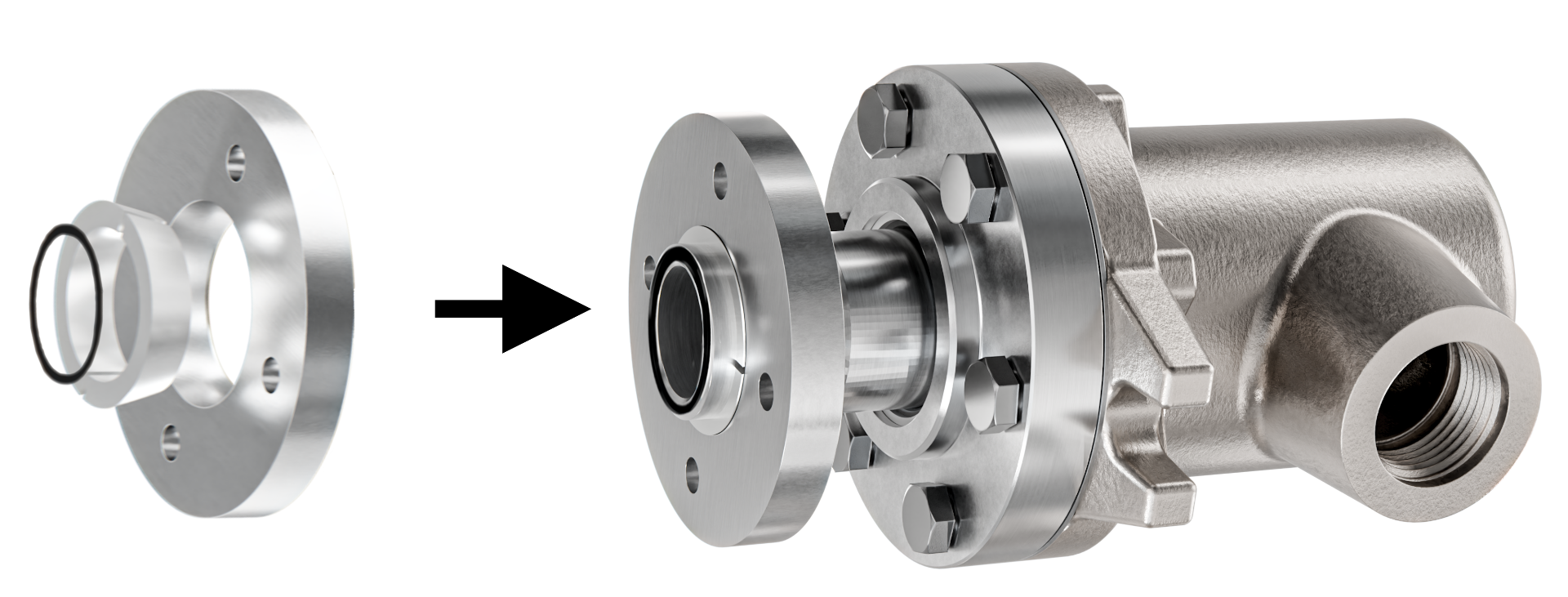

- Quick-release flange versions

Application areas: when to choose the Z-joint

The Z-joint is an ideal choice for industries that need precise and reliable thermal control in high temperature diathermic oile environments.

Its features make it particularly suitable for:

- Chemical industry: where safety is a priority and fluids must be transferred with absolute tightness.

- Pharmaceutical industry: where processes must be stable and controllable under all conditions.

- Plastics and rubber: for high repetitive thermal cycles.

- Printing / Converting / Flexo: where temperature control is critical for final product quality.

Low maintenance and long service life: the practical advantages

One of the main advantages of the Z series is low maintenance due to its modular design and high quality materials. A complete ready-to-use repair kit, consisting of:

- - Spring

- - Graphite bearing

- - Locking pin

- - Graphite seal

- - Flat gasket

- - Support bush

- - Seeger

This extends joint life, reduces downtime costs, and improves overall plant productivity.

An investment that makes a difference

Choosing the Z rotary joint means banking on a reliable, versatile component designed for complex industrial environments. The combination of advanced materials, customizable configurations and ease of maintenance make it an ideal solution for any plant operating with diathermic oil at high temperatures.

Author of the article

Victor Caronni – Marketing Manager

Victor Caronni is a Marketing Manager with extensive experience in B2B industrial marketing and technical communication.

He personally create, plans, and executes strategies, campaigns, and content for the Kadant and Johnson-Fluiten brands, overseeing every stage of the process.

He specializes in integrated digital marketing strategies that align with business objectives and deliver a direct impact on revenue.

His approach combines strategic vision with hands-on execution, ensuring that every initiative generates measurable and lasting results.

Author profile  LinkedIn

LinkedIn

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

Our goal is to work closely with our customers to develop reliable, efficient and technically advanced products that add value by improving the process and quality of the final product.

Contact us and one of our experts will be available for any of your needs!

info-jf@johnson-fluiten.com

+39.023394091

The rotary joint is an essential component for many industrial applications requiring fluid transfer. Learn about the diathermic oil rotary joint, ideal for systems operating at high temperatures. It uses a high-temperature, double-pass rotary joint to ensure efficiency in complex thermal processes. A rotary joint with a graphite seal ensures reliability and durability even under severe conditions. Graphite bushings make the rotary joint extremely resistant to wear and high temperatures. The rotary joint with Q flange is designed for easy in-line assembly and maintenance. The rotary joint with threaded sockets is compatible with widespread industry standards such as BSP. Rotary joints with flanged sockets are ideal for secure, high leakage connections. Choose a low-maintenance rotary joint to reduce downtime. A rotary joint for 300°C is the perfect solution for systems with high-temperature thermal oil. The rotary joint for 500 rpm is designed for high and stable performance. Antimony-impregnated graphite seal improves the chemical resistance of the rotary joint. The rotary joint with nodular cast iron body provides mechanical strength and long service life. Compressed carbon fiber seal ensures sealing even under high pressure. Rotary Joint for Chemical Industry: ideal for aggressive fluids and corrosive environments. Rotary Joint for Pharmaceutical Industry meets safety and cleanliness standards. A rotary joint for Plastics Industry withstands intense and continuous thermal cycles. Rotary Joint for Rubber Industry: reliable performance in high temperature environments. Rotary Joint for Printing Industry ensures consistent thermal control in production processes. A rotary joint for Converting Industry improves accuracy and final product quality. Learn about the rotary joint for Packaging Industry: suitable for automatic lines and rapid systems. Rotary Joint for Textile Industry is designed for continuous and intensive operating conditions. Rotary Joint with High Thermal Resistance: designed for processes with hot and continuous flows. A rotary joint with High pressure resistance protects the system from overloading. The compact and robust design of the rotary joint facilitates its integration even in small spaces. Diathermic oil compatible rotary joint for maximum thermal efficiency. Single-pass rotary joint is the ideal solution for simple and direct circuits. Double-pass rotary joint with rotating tube: perfect for simultaneous transfer of two fluids. A double-pass rotary joint with fixed pipe improves stability in complex thermal circuits. The BSP ISO228 threaded connections of the rotary joint ensure its universality of use. The rotary joint with quick-release flange speeds up routine maintenance operations. Choose a rotary joint with integrated support to simplify in-line installation. The customizable rotary joint is designed to fit each specific installation requirement. - Rotary joint - Rotary joint for diathermic oil - High-temperature double-pass rotary joint - Rotary joint with graphite seal - Rotary joint with graphite bushings - Rotary joint with Q flange - Rotary joint with threaded sockets - Rotary joint with flanged sockets - Low-maintenance rotary joint - Rotary joint for 300°C - Rotary joint for 500 rpm - Rotary joint with graphite ring impregnated with antimony - Rotary Joint with nodular cast iron body - Rotary Joint with compressed carbon fiber seal - Rotary Joint for Chemical Industry - Rotary Joint for Pharmaceutical Industry - Rotary Joint for Plastic Industry - Rotary Joint for Rubber Industry - Rotary Joint for Printing Industry - Rotary Joint for Converting Industry - Rotary Joint for Packaging Industry - Rotary Joint for Textile Industry - Rotary Joint High Thermal Resistance - Rotary Joint High Pressure Resistance - Rotary Joint Compact and Robust Design - Rotary Joint Compatible with Diathermic Oil - Single Pass Rotary Joint - Double Pass Rotary Joint with Rotating Tube - Double Pass Rotary Joint with Fixed Tube - Rotary Joint with BSP ISO228 Threaded Connections - Rotary Joint with Quick Release Flange - Rotary Joint with Integrated Support - Customizable Rotary Joint