History of the rotary joint: How this invention changed industrial engineering forever

When you look at the heart of any advanced manufacturing line, whether it’s a paper mill, a food processing plant, or a high-speed CNC machine, you’ll find a component working tirelessly behind the scenes: the rotary joint. Industrial engineers, production and maintenance managers know the pain of fluid leaks, frequent maintenance, and costly downtime. But what if the solution was a single innovation that transformed how industries harness water, steam, and other fluids in motion?

The Origins: Sealing the Challenge

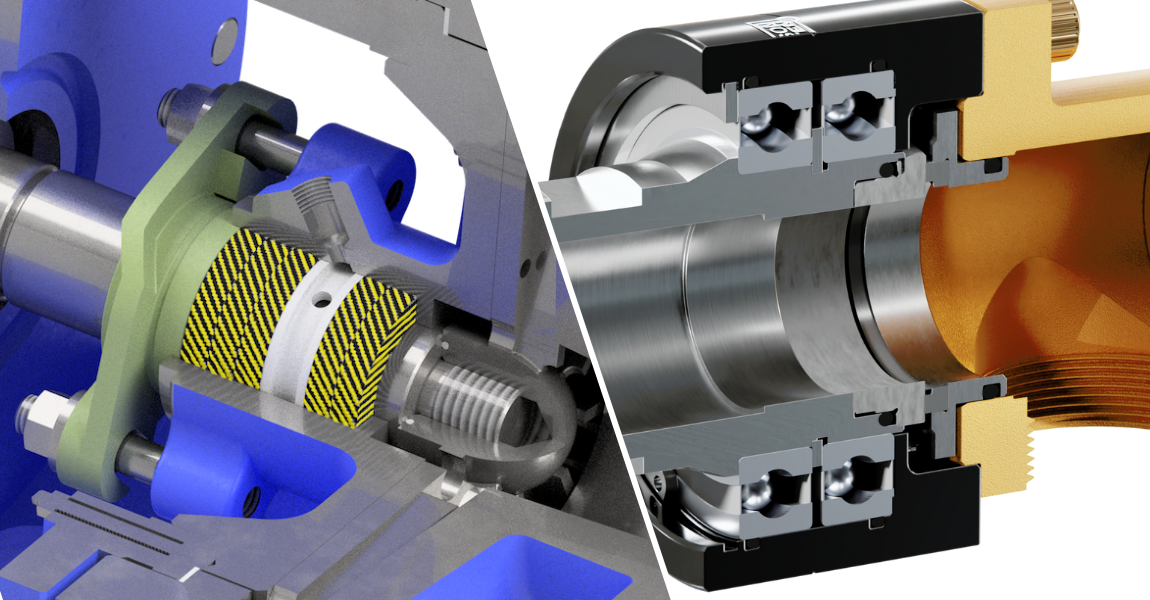

In the 19th and early 20th centuries, industries faced a persistent challenge: how to reliably supply water or steam to rotating cylinders. The answer, for decades, was the stuffing box or packing gland. While these devices worked, their design was fundamentally flawed; the more the seal wore, the more it leaked. Frequent leaks meant wasted resources, production interruptions, and ongoing maintenance headaches for plant operators.

Pain Points in Early Rotary Sealing:

- - High Maintenance: Constant adjustments and replacements required.

- - Inefficiency: Loss of steam/water led to energy and product waste.

- - Downtime: Leaks often forced unplanned stops in production.

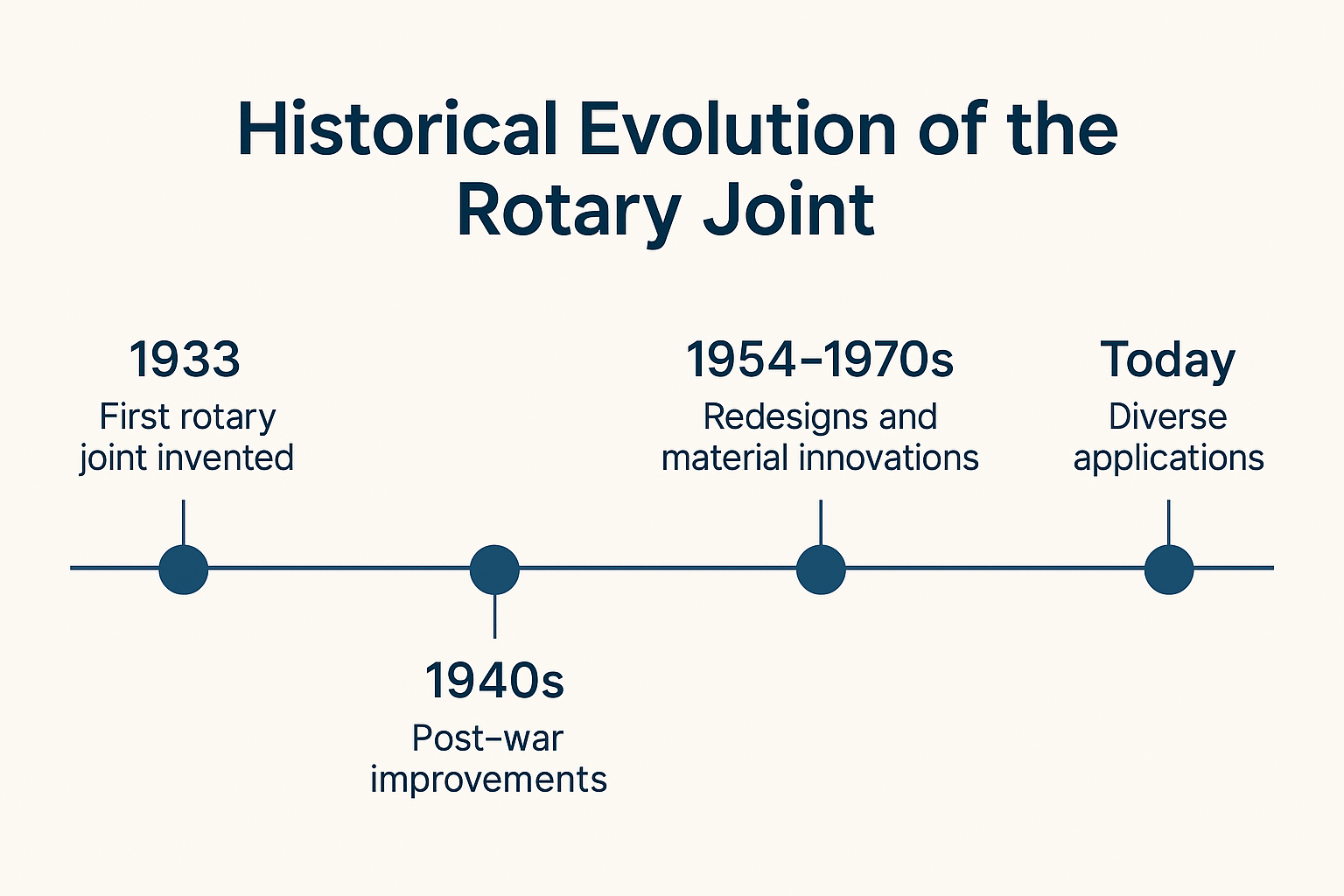

The Breakthrough: The First Rotary Joint

The turning point came in August 1933, when R.O. Monroe and L.D. Goff, in partnership with a local mill, designed and built the first rotary joint. Their device replaced unreliable stuffing boxes with a spring-loaded mechanical seal. The innovation was simple yet brilliant:parts of the joint rotated with the machine, while a robust mechanical seal kept fluids exactly where they needed to be; inside the system.

Post-War Innovation: Building on the Breakthrough

As rotary joints gained traction throughout the late 1930s and 1940s, the demand for higher performance and easier installation grew. Post-World War II, the next wave of innovation arrived: flexible metal hoses. This upgrade provided joints with the ability to absorb movement and wear, dramatically increasing their lifespan.

Comparison of the cross section of a stuffing box (left) and a rotary joint (right)

The 1954 Redesign: More Compact, More Capable

By the mid-1950s, rotary joint manufacturers, including innovators like Kadant Johnson, recognized a new challenge: applications required smaller, more specialized joints. A complete redesign was undertaken to minimize unit size and optimize for specific machine requirements. Results of the Redesign:space-saving designs (Easier integration into complex machinery) - performance focus (Improved heating/cooling efficiency in rotating cylinders)

The Research Era: Science Meets Industry

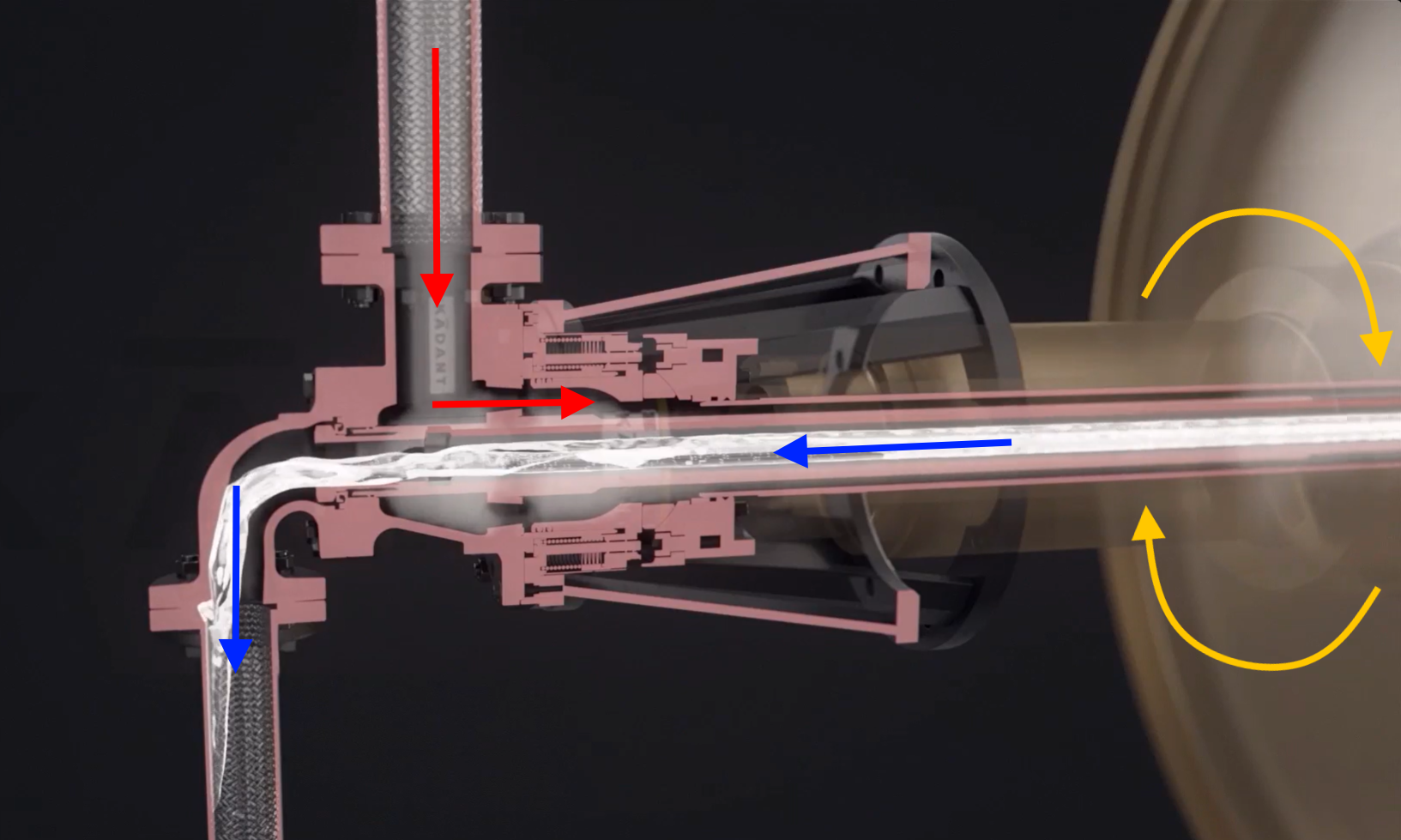

The late 1950s brought a critical shift; industrial efficiency became paramount. As industries sought to improve the heating and cooling of rotating cylinders, Kadant Johnson led the charge with extensive research into syphoning devices and joint design.

-

- Syphoning Technology: Both rotary and stationary types tested for optimal heat transfer.

-

- Clearances and Flow Rates: Fine-tuned for maximum operational efficiency.

By 1962, Kadant Johnson established a dedicated research facility in Michigan. In 1963, the first ever footage of the inside of an operating dryer cylinder was captured, providing unprecedented insights for engineers worldwide like: Steam Condensing Rates (improved understanding led to smarter designs) - collaboration (rotary joint and syphon knowledge was shared across industries).

Section and operation of a PT2X rotary joint from Kadant

Innovation Accelerates: Material Science and Customization

As industries demanded higher operating temperatures and faster speeds, rotary joint design had to adapt again. Innovations included:

- 1. Quick Replacement Desing: For faster maintenance

- 2. Expanded Material Options: Introduction of plastics, Teflon™, ceramics.

- 3. Self-Supported and Externally-Supported Designs

- 4. Single, Dual and Multi Flow Configurations

- 5. Compatibility with different media like Water, Air, Oil, Gas, and More

- 6. Operating Temperatures up to 1,000° F (538° C)

- 7. Speeds up to 50,000 RPM

Why Modern Industries Depend on Rotary Joints

Industrial professionals understand that rotary joints are essential components for ensuring operational continuity, efficiency, and safety across a wide range of applications. In paper manufacturing, they enable reliable steam and water delivery to drying cylinders; in machine tools, they supply coolant and oil to high-speed spindles; in food processing, their sanitary design ensures leak-free, safe operation; and in chemical processing, they withstand aggressive fluids and extreme temperatures. These applications translate into measurable benefits: reduced unscheduled downtime thanks to reliable sealing, lower energy consumption due to efficient fluid transfer, improved product quality through consistent process control, and optimized maintenance schedules enabled by advanced materials and design innovations.

Some industrial applications in which rotary joints are used

Author of the article

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091