For decades, Nordmeccanica, a company known worldwide for its laminating machines and metallisation machinery, has been using Johnson-Fluiten components to give its solutions the reliability its customers expect.

A long-lasting partnership based on the perfect match of Johnson-Fluiten components to Nordmeccanica's needs, the very low maintenance requirements and the supplier's willingness to meet every customer request.

For more than 45 years, Nordmeccanica, a company from Piacenza but present in more than 87 countries around the world, has been designing and manufacturing machinery for coating, laminating and metallisation of materials in coils, mainly used for flexible packaging. Over these decades, the company has evolved rapidly, growing from a 3,000 square metre plant to the current 33,000 square metres, with a production capacity that places it at the top of the segment worldwide.

Nordmeccanica's offer is extremely diversified: it ranges from simple coating machines to complex machinery capable of handling different materials to obtain laminates and even three-layer solutions. The company also offers innovative metallizing machines that rely on a vacuum system to offer exceptional performance in terms of production speed and finished product quality.

In addition to the dozens of proven products in the catalogue, capable of satisfying the requirements of most companies, there are also customised solutions that Nordmeccanica is able to create from tested modules to offer a reliable machine with performance perfectly tailored to the customer's needs in a short time.

The importance of flexibility

With such a wide range of machinery, it is easy to think that Nordmeccanica needs a large variety of different components, resulting in a rather complex stock management. In reality, the partnership with certain suppliers, capable of producing extremely versatile components, has made this aspect of production much easier.

One of these is Johnson-Fluiten, a company that has been producing rotary joints for a wide variety of applications for more than 20 years. This supplier's components are appreciated for their exceptional tightness, robustness, durability and reliability, but particularly for their ability to adapt to the different fluids used in the production process.

Thanks to this flexibility, Nordmeccanica was able to identify two models in the range of rotary joints produced by this supplier with which it is able to complete the vast majority of its projects.

This has allowed Nordmeccanica a considerable standardisation in component orders, which, thanks to the flexible use of rotary joints, does not affect the differentiation in machinery production.

Standardisation has several advantages: from the customer's point of view, it allows them to make larger volume orders of each reference and consequently obtain more competitive commercial conditions, while the supplier is able to better plan production and stock management, which makes it easier to guarantee on-time deliveries.

A multi-purpose design

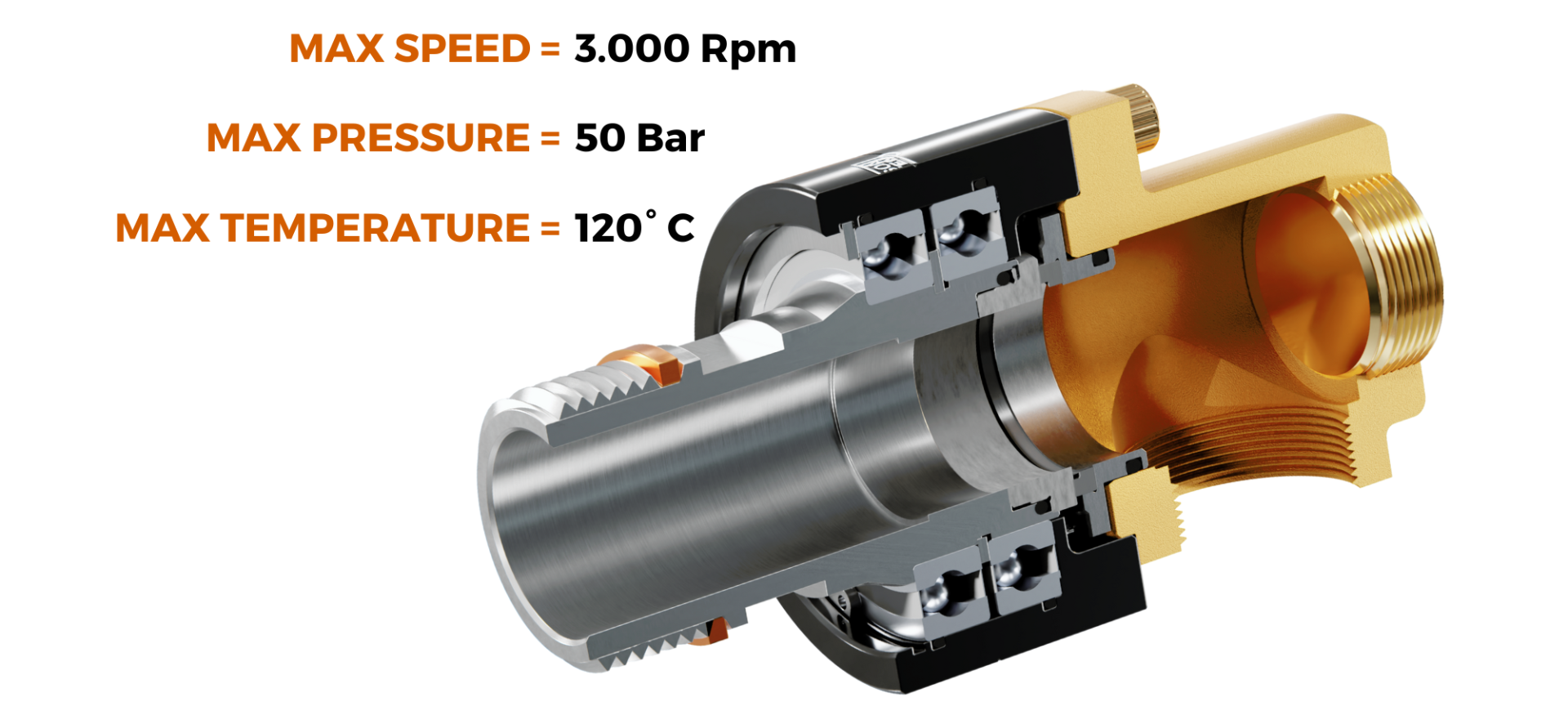

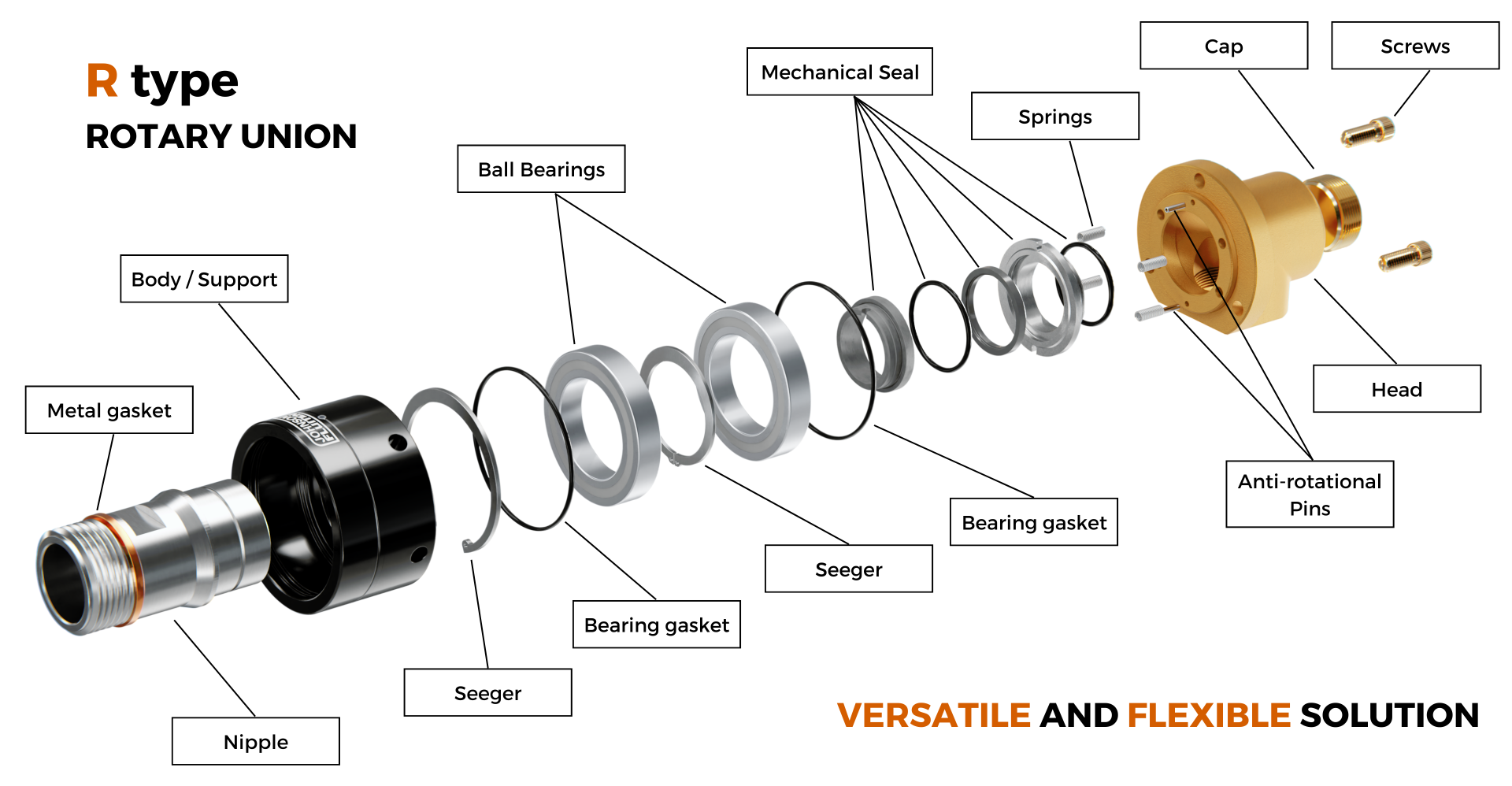

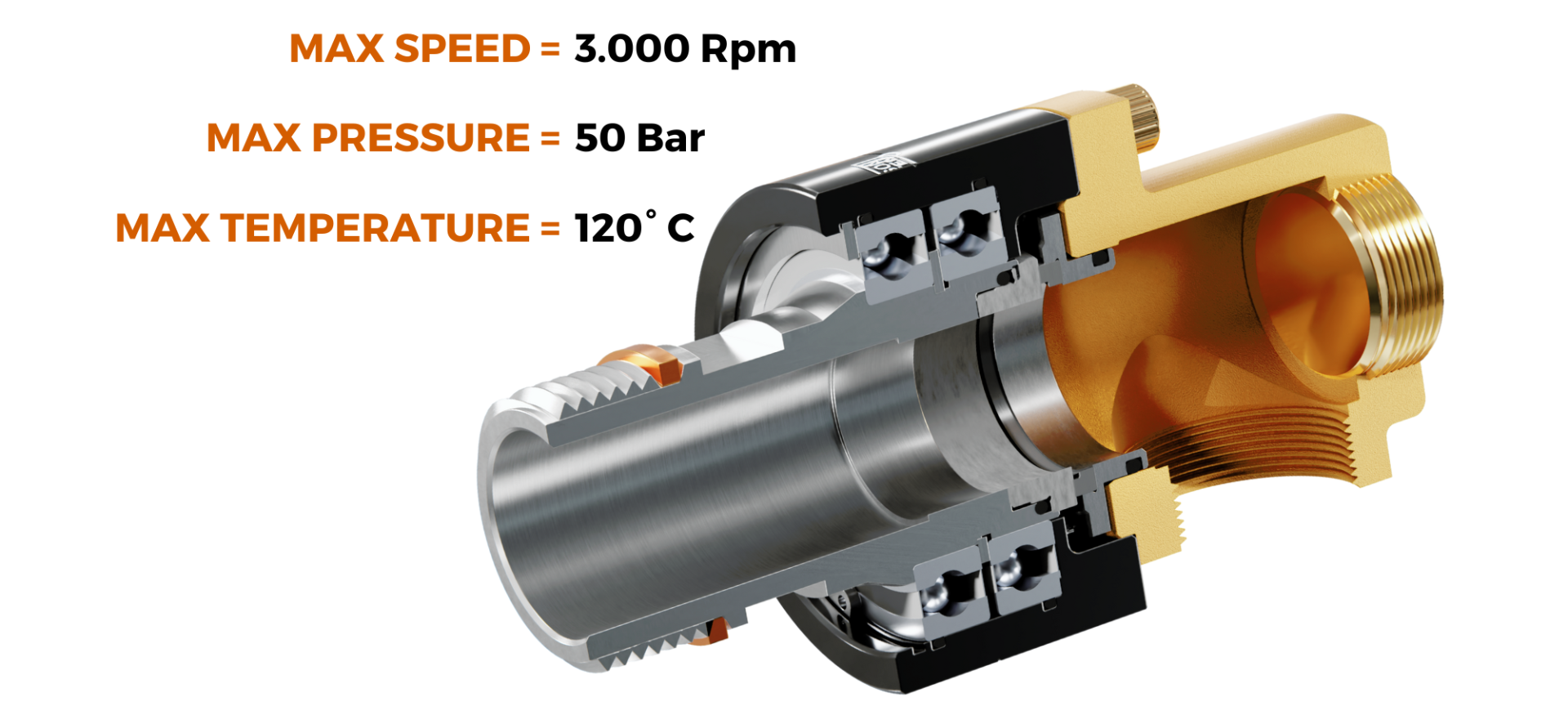

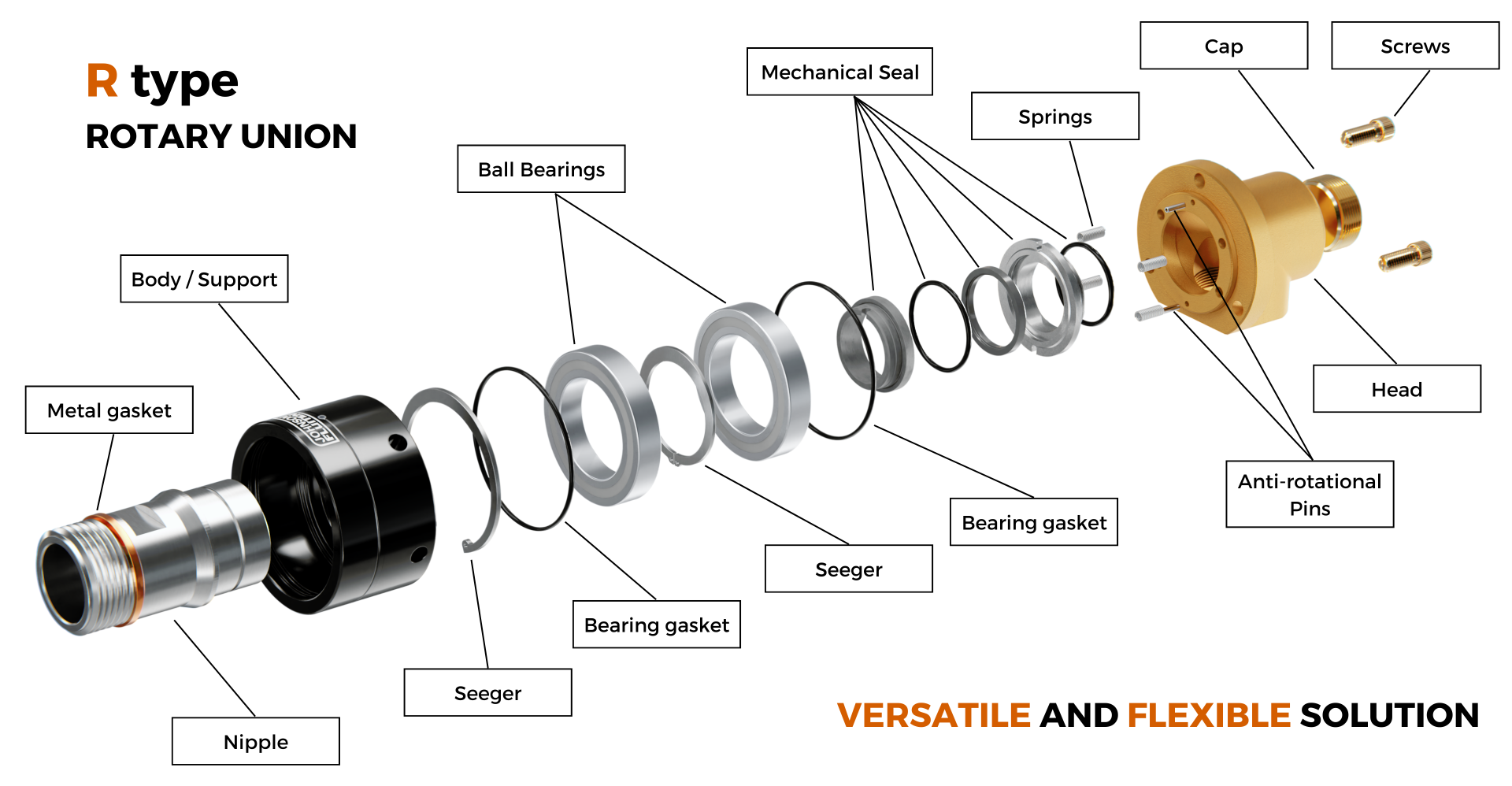

Among the many different types of rotary union produced by Johnson-Fluiten, Nordmeccanica has chosen

R SERIES joints in two sizes; ¾" and 1". The

R SERIES rotary joints are particularly suitable for handling water at different temperatures and pressures. One of the most distinctive aspects of these components is the adoption of a

micro-lapped mechanical seal, which guarantees a smooth and complete fluid passage. This not only improves process efficiency, but also lubricates the seal itself, prolonging its life and reducing the need for maintenance.

In addition to this, the balanced mechanical seal is designed to handle high-pressure applications, representing invaluable added value. With symmetrical faces that distribute pressure equally, this technology minimises heat generation and friction during operation. This translates directly into reduced seal face wear, significantly extending the life of components and offering significant savings in maintenance and replacement costs.

For an industrial machinery manufacturer, choosing

R SERIES rotary joints means investing in a solution that not only optimises performance, but also helps reduce operating costs in the long run.

With

¾ and 1-inch SERIES R rotary joints, Normeccanica

can produce more than 90% of the machinery it manufactures. For the rest of the equipment, which is generally custom-built, where tailor-made solutions are required, Johnson-Fluiten's engineers are always on hand to identify the most suitable union from the extensive catalogue or, if necessary, to adapt an existing union joint or design a custom one quickly.

No maintenance required

For a manufacturer such as Nordmeccanica, which exports a large share of its machinery all over the world, it is essential to have components that are maintenance-free, reliable and long-lasting at all times, so as to minimise the risk of the company's technicians having to make long and expensive transfers to carry out repairs.

With Johnson-Fluiten joints, the goal is achieved: maintenance requirements are practically zero and operation is reliable and constant. The service life is also remarkable: robust and manufactured from carefully selected materials, they withstand heavy use for as long as the service life of the machine.

Strongly recommended

So great is Nordmeccanica's confidence in Johnson-Fluiten components that they have, from time to time, recommended them to customers who had specifically asked for unions from other manufacturers, only to find that they performed less than optimally. On Nordmeccanica's advice, they switched to Johnson-Fluiten rotary joints and appreciated the resulting improvements in manufacturing efficiency.

Because of all these positive characteristics, Nordmeccanica has no reason to consider alternatives: the company is perfectly satisfied with its collaboration with Johnson-Fluiten and expects it to continue for a long time to come.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

Our goal is to work closely with our customers to develop reliable, efficient and technically advanced products that add value by improving the process and quality of the final product.

Contact us and one of our experts will be available for any of your needs!

info-jf@johnson-fluiten.com

+39.023394091