Trends and forecasts, what does the future hold for the manufacturing enterprise?

After meeting the leading companies at the trade show, it is time to take an evaluation of the current situation and the future of the Italian industry

Italian manufacturing does not slow down and, in fact, came together again in Bologna at the 20th edition of Mecspe, the exhibition of manufacturing and technological innovations for industry.

Thanks to the great success of this event, it was finally possible to meet 'face to face' all the major players in the sector and share with them some thoughts on the trends and forecasts of the whole industrial sector.

What is really important for companies today?

On-time delivery is becoming more and more important in business. The global market is more connected than ever before, and companies are increasingly focused on finding solutions to get their products to customers as quickly and cost-effectively as possible.

Unfortunately, the mood in the industry today is marked by great uncertainty. The general price level is rising, international trade is showing signs of slowing down and the logistics industry is struggling to meet current demand.

Forecasts on manufacturing industry trends

Italy's GDP is expected to continue to grow in the second half of 2022 (+2.8%) and in 2023 (+1.9% - Source: ISTAT), but more slowly than expected. Experts claim that this increase will be mainly driven by the contribution of domestic demand, while a decrease in international trade is expected. The coming months promise to be unstable, risks include; a further general increase in prices, a downturn in global trade and an increase in interest rates.

The evolution of Covid-19 infection and international tensions have aggravated difficulties in business relationships with all suppliers, underlining the need for companies to adopt efficient and effective procurement practices. In the current situation, it is more important than ever for companies to be able to keep up and remain competitive.

The procurement and supply chain structure at Johnson-Fluiten

Despite the fact that manufacturing companies have had to deal with an extraordinary, and sometimes uncontrolled, increase in delivery times over the past year; thanks to its network of partners and investments in production and warehousing departments, JF is now able to confirm orders within the standard pre-crisis deadlines.

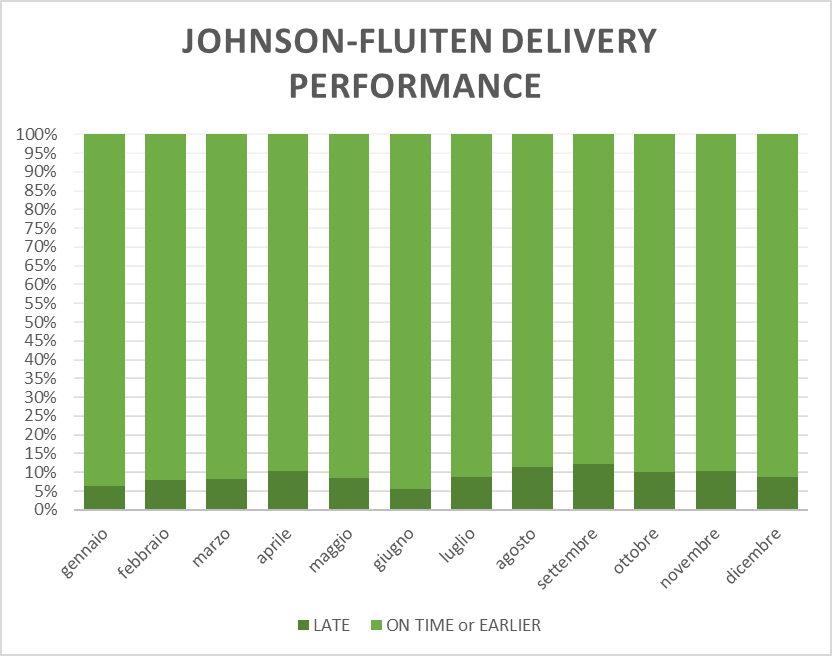

Delivery performance summary from 01-01-2021 to 31-12-2021

You only have to look at the numbers to realise the exceptional delivery performance: in 2021, out of all the orders fulfilled, the 91% were completed IN or even BEFORE the agreed deadlines; in particular, 25% of the total deliveries were completed in advance of the order confirmation date.

And where there were postponements, the delays were very limited; the average, calculated on all orders that were delayed from the promised date, was only three days.

This is an extraordinary achievement when compared to the market standard, and this result appears even more significant when one considers that most of the rotary joints handled by Johnson-Fluiten involve CUSTOM products and SPECIAL projects made according to specific customer requirements.

Exceeding expectations, the daily goal at Johnson-Fluiten

How was it possible to provide better conditions than the current market standard?

Thanks to a careful analysis of the national and international scenarios, and the close and constant cooperation with the companies of the KADANT group (a leader in the production and sales of rotary joints), Johnson-Fluiten has increased investments in the production and procurement departments, which has already allowed it to have large stocks of material available by the end of 2021.

"At Johnson-Fluiten, the customer really always comes first... our service is a competitive advantage that the market acknowledges, and that our customers also appreciate..."

Marco Golla - Sales Director of Johnson-Fluiten

The flexibility of the supply chain and the ability to develop most components in-house (and not having to rely on third-party suppliers) is one of the reasons for Johnson-Fluiten’s success today.

La versatilità della catena di approvvigionamento e il poter sviluppare la maggior parte dei componenti all’interno dell’azienda (e non doversi affidare a fornitori terzi) sono oggi uno dei motivi del successo di JF, e rappresentano un vantaggio unico per tutti i clienti.

With the new automated warehouse, it is even possible to process an order in 24 hours from receipt, allowing, for rotary joints and other standard products, immediate delivery. An exclusive service for all those companies that need to receive a spare part as soon as possible, to avoid unplanned machine downtime.

The importance of reliability and flexibility

The challenges that industry in our country faces these days are several; instability, rising costs and difficulties in the supply chain. It is essential therefore to be able to choose professional partners, with long experience behind them and above all solid and reliable.

Johnson-Fluiten can rely on the global network of Kadant Johnson Europe B.V., and on Fluiten's knowledge and production capacity, these features allow to be a benchmark in the design and manufacture of rotary joints for water, thermal oil and coolant applications.

Test Johnson-Fluiten’s expertise and know-how, our team of experts will be happy to find the best solution for you.