From customer to long-term partner; the emphasis on true product and service quality in the machine tool industry

Trevisan Macchine Utensili's machine tools and Johnson-Fluiten rotary joints share manufacturing processes that are for the most part performed in-house to ensure total control and excellent performance: a shared vision that explains the successful collaboration between the two companies.

For 60 years, "Trevisan Macchine Utensili" has been a well-known and appreciated name worldwide for the reliability and accuracy of its solutions for the mechanical industry. Among the features that have ensured the company's success is its ability to customise solutions according to customer requirements and the efficiency and punctuality of its after-sales service.

The workstations, CNC lines and special machines of Trevisan Macchine Utensili have been purchased by companies operating in many different industries, from the energy to the agricultural sector, passing through the space, aeronautical, naval, automotive, mechanical and oil & gas, in all cases being recognised for their excellent performance and crucial support to the competitiveness of the production processes in the companies that have chosen them.

The company's success is driven by its ability to achieve excellence at all stages of the production process, from design to manufacture: most machining, finishing, quality control, assembly and testing are carried out in-house, ensuring that every aspect meets the high standards required by customer companies.

Careful control of components

With these assumptions, it is reasonable to expect the application of very high standards also for the selection of special components, which, however, must be purchased from specialised companies.

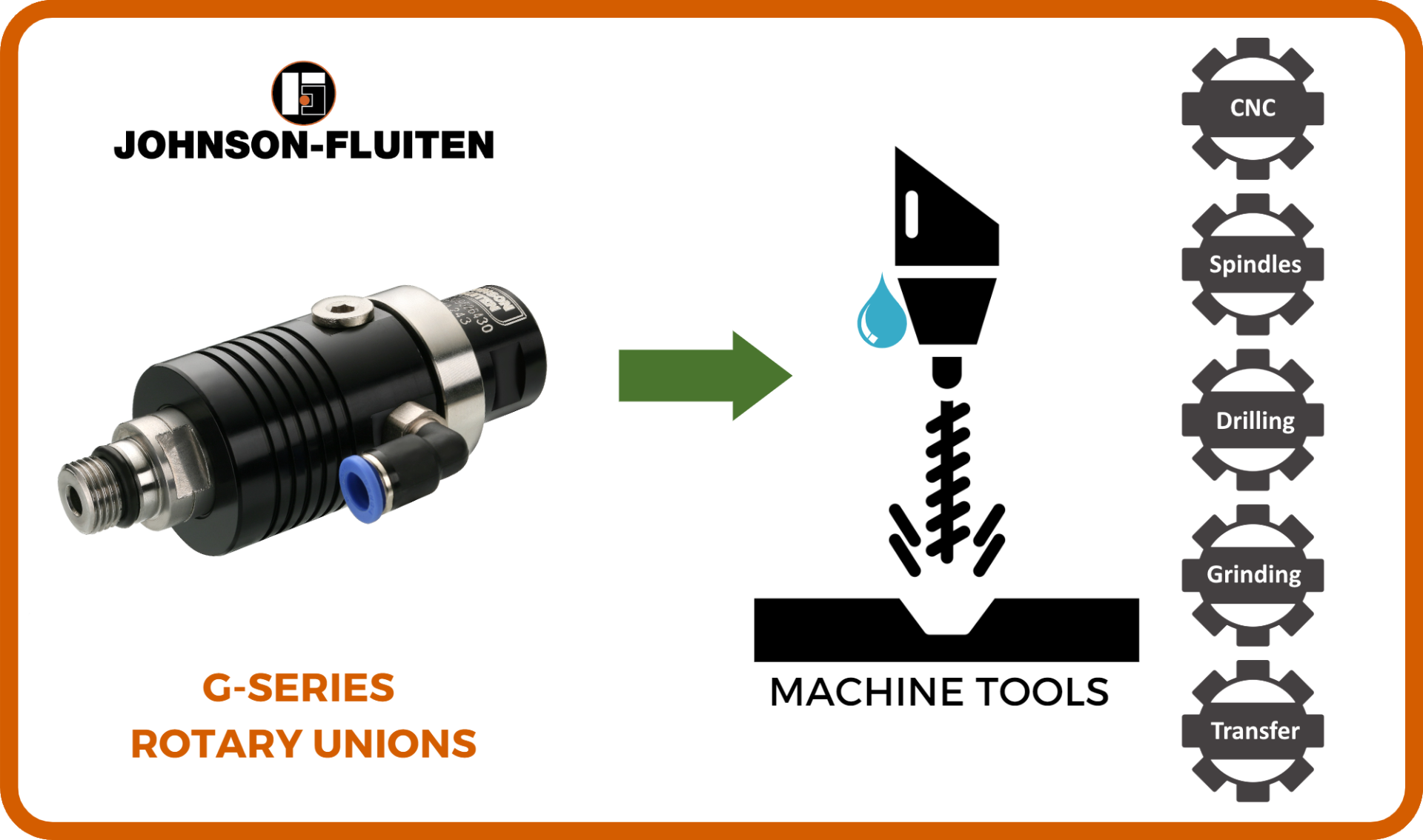

These include rotary joints, which are essential in machine tools: the heat developed during machining requires the tool to be properly lubricated to prevent it from overheating and to allow uniform machining. To get the lubricant to the tool, a rotary joint is needed, whose strength and tightness must ensure a constant supply of fluid, in the right quantities and only where needed, at all stages of machining.

Many years ago, Trevisan Macchine Utensili decided to test alternatives to the couplings it normally used: the search for solutions available on the market led the company to Johnson-Fluiten, which has been designing and manufacturing rotary joints for water, steam, oil and coolant applications for over twenty years.

"The Johnson-Fluiten technicians were confident in the value of their solutions, which they allowed us to test without any commitment....

And we immediately agreed that they were right: beyond the minimal difficulties associated with any change of components, which we quickly overcome with the help of the supplier, the performance immediately proved to be brilliant, completely up to expectations."

Rossella Trevisan, titolare Trevisan Macchine Utensili

Efficient and adaptable

Among the features of Trevisan Macchine Utensili production, which allow the company to supply high-performance solutions to companies in all industrial segments, we should certainly mention the careful design, capable of combining a high level of customisation of the finished system with a certain degree of standardisation of the components, which allows efficient warehouse management.

"We try to use the same rotary joints as much as possible for all our solutions, which are many and ranging from work centres for processing small parts to oversize machines, from turning lines to special solutions...

Finding a single joint that fits the different scenarios that come in such a wide range of machinery is not easy, but the Johnson-Fluiten solutions have proven to have this capability"

Rossella Trevisan, titolare Trevisan Macchine Utensili

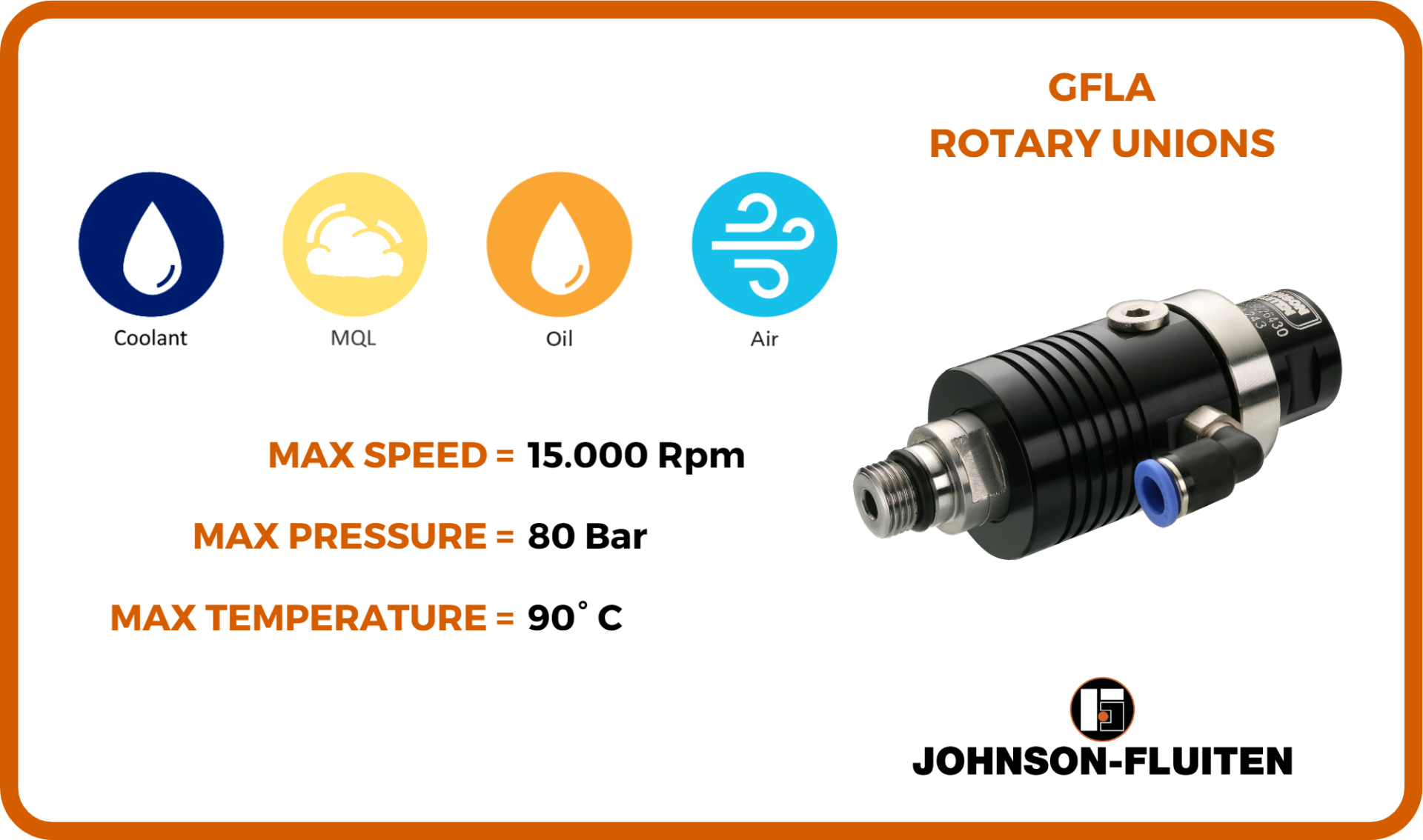

Johnson-Fluiten rotary joints are actually very versatile: unlike most joints on the market, which can adapt to changes in only one operating condition (speed, pressure, temperature or type of fluid), these solutions can be used in all conditions, thanks to the special mechanical seal. This greatly simplifies several aspects of the production and management process, greatly reducing the number of part numbers that need to be kept in stock, with advantages for logistics and productivity that Trevisan Macchine Utensili has been able to appreciate and put to advantage.

In detail, the component chosen for most projects is a Series G rotary joint, in the GFLA version with radial connection, which is particularly suitable for high-dynamic applications using coolants. Special machining of the silicon carbide sealing faces makes these joints highly resistant to wear and thermal shock, while the labyrinth sealing system ensures efficient protection of the ball bearings from leakage.

The component requires no maintenance and has a very long service life, a key feature to reduce the need for interventions and particularly appreciated by those who, export machinery all over the world and understandably take every precaution to avoid the need for costly trips to maintain them.

G-Series couplings allow minimizing vibrations, frictional torque and pressure drops, enabling a constant machining performance, optimizing efficiency and thus production competitiveness.

The emphasis on service

The perfect seal, reliability and endurance of Johsnon-Fluiten rotary joints are not the only features behind this long-standing partnership. In fact, like all of Johnson-Fluiten's customers, Trevisan Macchine Utensili has had the opportunity to appreciate the elements that shape the pre- and after-sales service.

In particular, the training of Johnson-Fluiten's technicians translates into consulting service, which also in the case of Trevisan Machine Tools was provided without any commitment from the first contact.

The ability to listen and understand the customer's needs allowed the technicians to obtain the right information to propose the most suitable solution in a short time; the experience and knowledge of the application sectors are the basis of the confidence with which Johnson-Fluiten was able to ensure the procurement of the optimal rotary joint for the production needs.

"The availability of the technicians, the on-time delivery and the constant support demonstrated over the years are as important as the quality of the products in determining the excellent relationship with Johnson-Fluiten; our relationship is set to continue for a long time with reciprocal satisfaction"

Rossella Trevisan, titolare Trevisan Macchine Utensili

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091