News DE

-

Categories: News DE

Eine jahrzehntelange Partnerschaft: Die Partnerschaft zwischen Boema, einem großen Hersteller von Ausrüstungen für die Lebensmittelindustrie, und Johnson-Fluiten, einem Unternehmen, das sich auf die Entwicklung und Herstellung von Drehdurchführungen spezialisiert hat, verdankt ihre Langlebigkeit dem gemeinsamen Qualitätsbewusstsein, aber vor allem der Fähigkeit, Herausforderungen zu meistern, indem man dank Fachwissen und Know-how die beste Lösung findet. Seit über vierzig Jahren ist Boemabei Kunden in der ganzen Welt für seine Systeme für die Lebensmittelindustrie bekannt. Die ständige Weiterentwicklung der Lösungen, um den Verarbeitungstechniken voraus zu sein, hat es Boema ermöglicht, zu wachsen u

-

Not all machine tools are the same, but all of them need components that guarantee high levels of performance such as: - high speeds - air and coolant - possibility of dry running - wear resistance - vibration reduction - minimum friction torque OUR SOLUTION Developing quality rotary joints that have all these features has been our goal for 20 years. But at Johnson-Fluiten

-

Johnson-Fluiten turns 20. The Milan-based company, founded in 2003 as a joint venture between Kadant-Johnson (then 'The Johnson Corporation') and Fluiten Spa, for the design and production of solutions for water, steam, oil and refrigerant fluid applications, combines the best aspects of the two entities: an American multinational with ninety years of history behind it and an Italian company appreciated for its creativity and flexibility. We talked about this business and its prospects in this double interview with Victor Caronni, Marketing Manager, and Marco Golla, Sales Director.

-

Jan 20 2023

SX® ROTARY JOINTS by KADANT JOHNSON

The self-supported SX rotary joint provides a positive seal between stationary piping and a rotating cylinder and is applied to steam, water, and hot oil service. The SX rotary joint incorporates two internal carbon-graphite bearings that permit self-alignment and long operating life, even on cylinders that are not concentric. Using new sealing technologies, the SX rotary joint has extended seal life and increased reliability along with application flexibility. The SX rotary joint line is available in sizes from 3/4” to 3” and can be used in single- or

-

Dec 28 2022

Carbon Fibre Guides or Ball Bearings?

The choice between a ball-bearing rotary joint or one supported by a carbon guide is affected by several factors, let's find out which ones. Both options feature a self-supporting structure that is used when there is no external structure to mount a rotary joint, or when the joint configuration and application do not require external support. For many applications, rotary joints with external ring support, such as the PTX® rotary joint or the CorrPro® rotary joint, are the best solution.

-

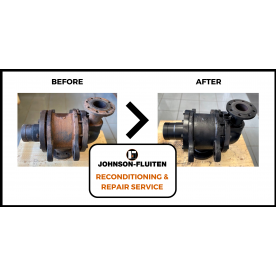

As good as new. Our rotary joint reconditioning service gives the product perfect functionality "as if it had just left the factory". We are so confident in the result that we guarantee it. All mechanical components have a 'life cycle' and when they are used in particularly heavy-duty applications, for parts exposed to normal wear and tear, it is necessary to carry out some checks and professional maintenance so that the system always works at its best. Let's take one of our customers as an example who treats animal waste (or also called 'rendering') with its plants. Treating slaughterhouse waste such as bones, blood, feathers, carcasses, leather, and turning them into bone and

-

Categories: News DE

Es ist Italiens wichtigst Fachmesse für Papier, Kartonherstellung und Verarbeitungstechnologien und findet vom 12. bis 14. Oktober in Lucca stattfindet. Das Hauptthema der MIAC wird die Energiefrage sein. Auch in diesem Jahr nehmenJohnson-Fluiten und KADANT wieder an dieser führenden Fachmesse teil, die sich als echte Referenz für alle nationalen und internationalen Marktteilnehmer der Zellstoff- und Papierbranche erweist. Zahlreiche Besucher aus der ganzen Welt werden nach Lucca kommen, um sich beruflich auf den neuesten Stand zu bringen und neue Geschäftsmöglichkeiten zu entdecken und auszubauen.

-

Categories: News DE

Unser Kunde COMERIO ERCOLE ist ein langjähriges und international renommiertes Unternehmen aus dem Bereich der Herstellung von Kunststoffverarbeitungsmaschinen und -anlagen, mit einem wichtigen Fokus auf F&E, Innovation und Qualität. Ihr Hauptaufgabenbereich ist die Herstellung von Maschinen und Anlagen für Gummi- und Kunststoffverarbeitung sowie für die Vliesstoffindustrie und spezielle Anwendungen. Das oberste Ziel des Unternehmens: dem Kunden die höchste Qualität sowohl beim Produkt als auch beim Service vor und nach dem Kauf zu garantieren. Aus diesem Grund widmen die technischen Teams allen F&E-Aktivitäten große Aufmerksamkeit und führen Grundlagenforschung, angewandte Forschung und vorwettbewerbliche experimentelle Entwicklungen durch. Das Team von Johnson-Fluiten hat sich in dieses Szenario eingearbeitet, indem es

-

The Corrugated and Paper & Pulp markets have always been a fundamental sector for Kadant Johnson and Johnson-Fluiten. On these markets, where we are the undisputed leader, we work with the main manufacturers worldwide and with all the end users. Therefore, we are able to offer customized solutions and utilize our expertise and tradition to build up the best options with our high-quality products. The first product that is most importantly supplied is the Rotary union, used to bring the steam inside the roller and to extract the condensate. Within many years of experience on the field, the Kadant Group has developed a rotary union with unique characteristics for this market, the CorrPro

-

Marco Golla works as a business developer in Johnson-Fluiten. Working for the company for more than 18 years, he has developed his expertise during the years and improved his skills even more to offer the best options to improve energy saving, efficiency and productivity in industrial processes. Q. Hi Marco. Thank you for making the time for this interview. How long have you been part of Johnson-Fluiten? Could you share your journey inside the company? A. To be honest I feel part of this company because I started my journey in Johnson-Fluiten when the company was established. My journey began long time ago in Fluiten, where I started in the technical office, when the drawings were still made on the drafting machine. I continued in the sales office as an internal sales manager of mechanical seals, and then I was assigned an area as an Area Sales Manager. It allowed me to get a lot of technical and commercial experience. Afterwards