Coating systems tested to automotive standards with Johnson-Fluiten components

Since 1973, Matex has been designing and manufacturing equipment for textile coating and finishing; in particular, machinery for the production of artificial leather is highly valued in sectors with demanding quality requirements such as the automotive industry.

For rotary joints, Matex has no doubt: the benchmark supplier is Johnson-Fluiten

Specialised in the creation of tailor-made systems for companies in a wide range of sectors, Matex is best known for its coating lines, capable of creating coated/laminated materials that are highly valued in the furniture, footwear, luxury goods and automotive industries.

Matex's coating machines, for example, allow the precise application on release paper or plastic films of the substances required for the production of materials such as eco-leather.

Matex is appreciated for the reliability and innovation of its solutions. The advantages of economies of scale provided by its high production capacity allow it to produce competitive machinery, while still meeting the quality standards of the most demanding sectors

The value of reliability

Matex's customers require machines that work perfectly but, above all, last a long time. This is why the company conducts meticulous checks at all stages of production, which naturally extends to the materials and components used.

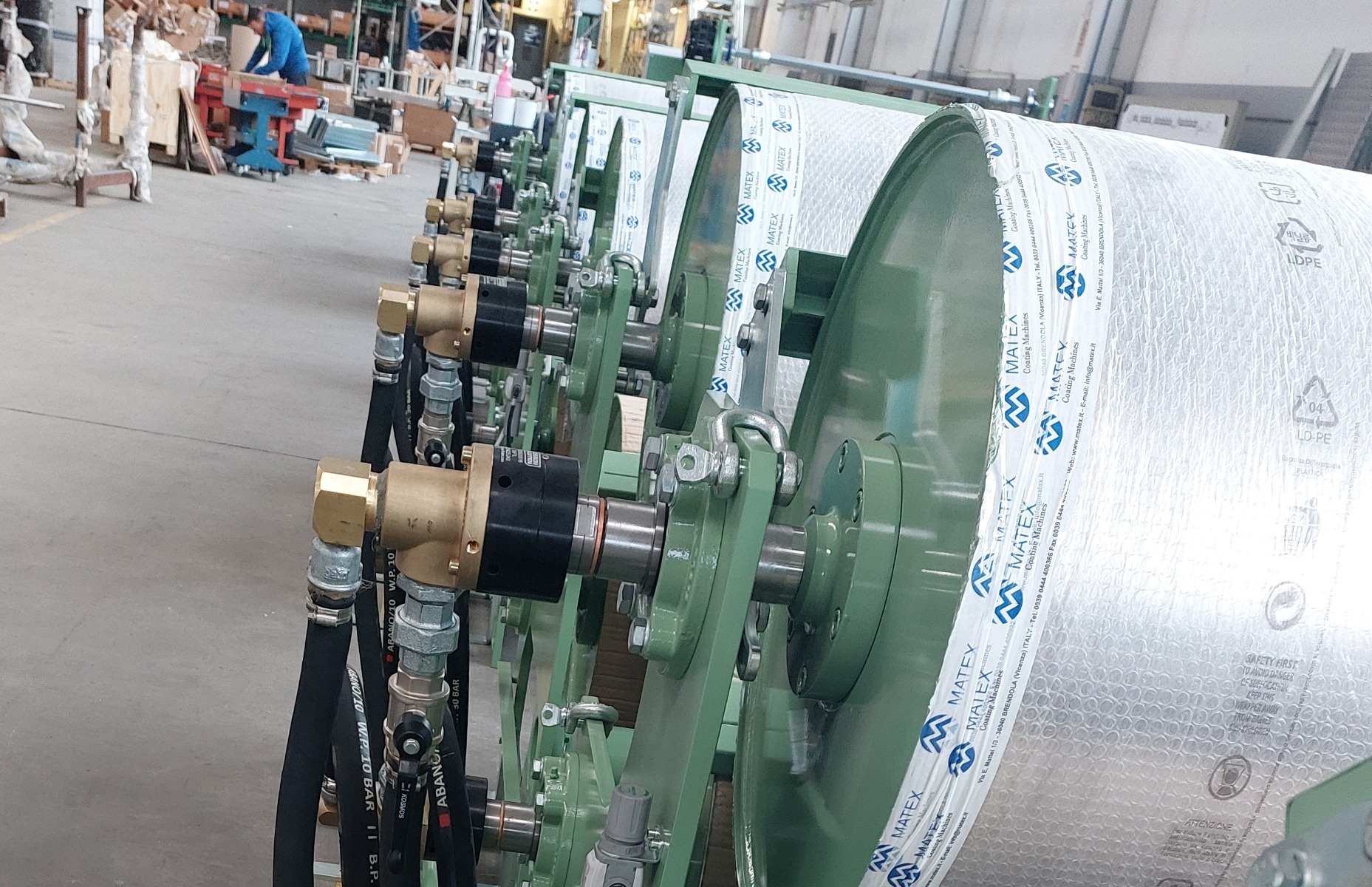

When it comes to rotary joints, which are required for cooling or heating the material processed in its machines, Matex has for decades relied on solutions from Johnson-Fluiten, which has been designing and manufacturing components for all kinds of applications since 2003.

But the partnership goes back even further than the founding of the company; Matex already had a successful business relationship with Fluiten, a company that later gave rise to the current Johnson-Fluiten following the joint venture with Kadant-Johnson. Proof that when you offer quality solutions that deliver concrete benefits, you create long-term professional relationships.

“By guaranteeing customers that they will have no problems with their joints, means that they can focus on process quality. Process quality means better, high-profile products that make Matex machines known for their reliability”, explains Marco Calcara, sales manager at Matex.

Other essential features that fluid handling components must provide are:

- 1) Maintaining performance over time; this provides better control over machines and chemical processes

- 2) The speed of delivery and service which are essential to be able to move in the international market

Sturdy and versatile components

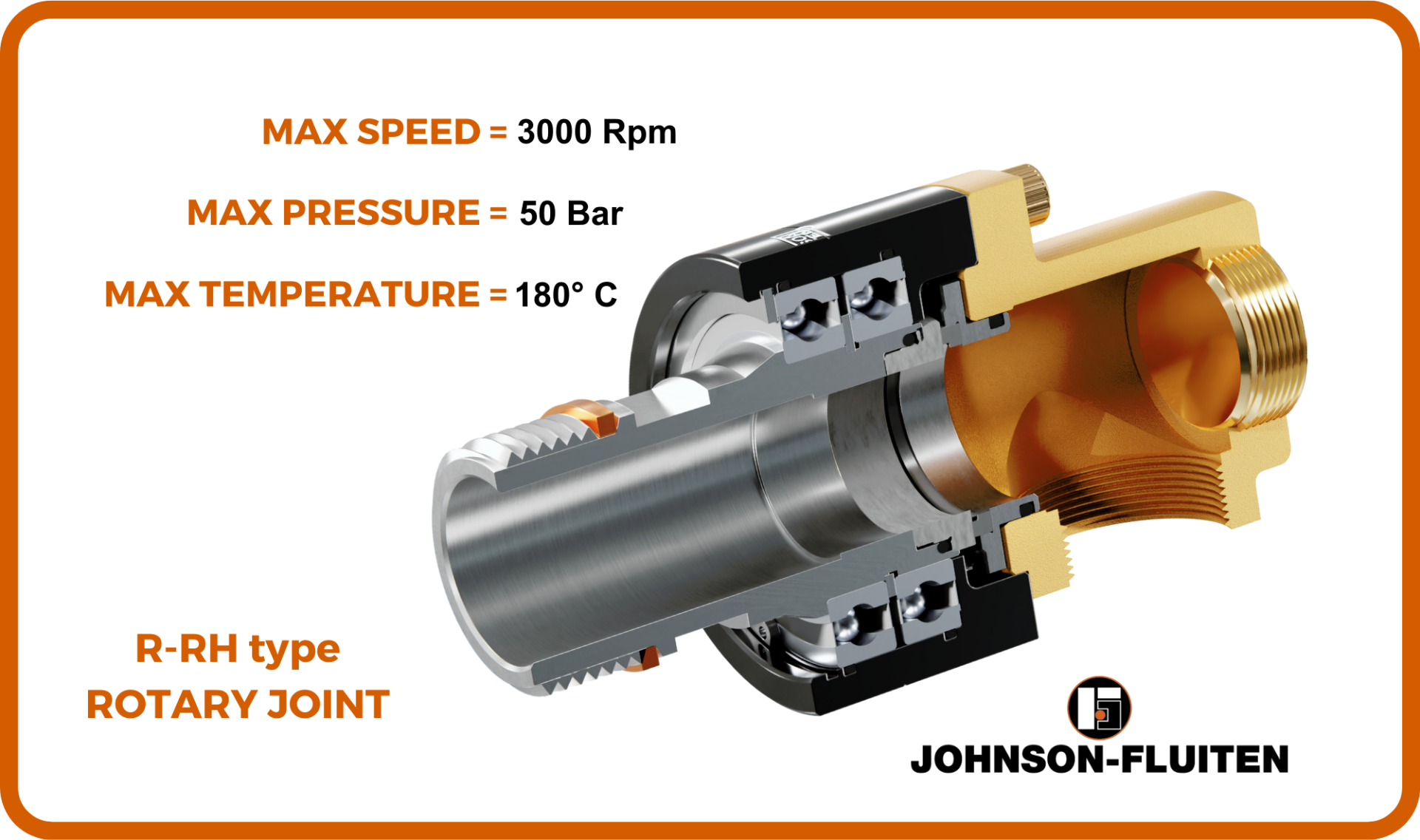

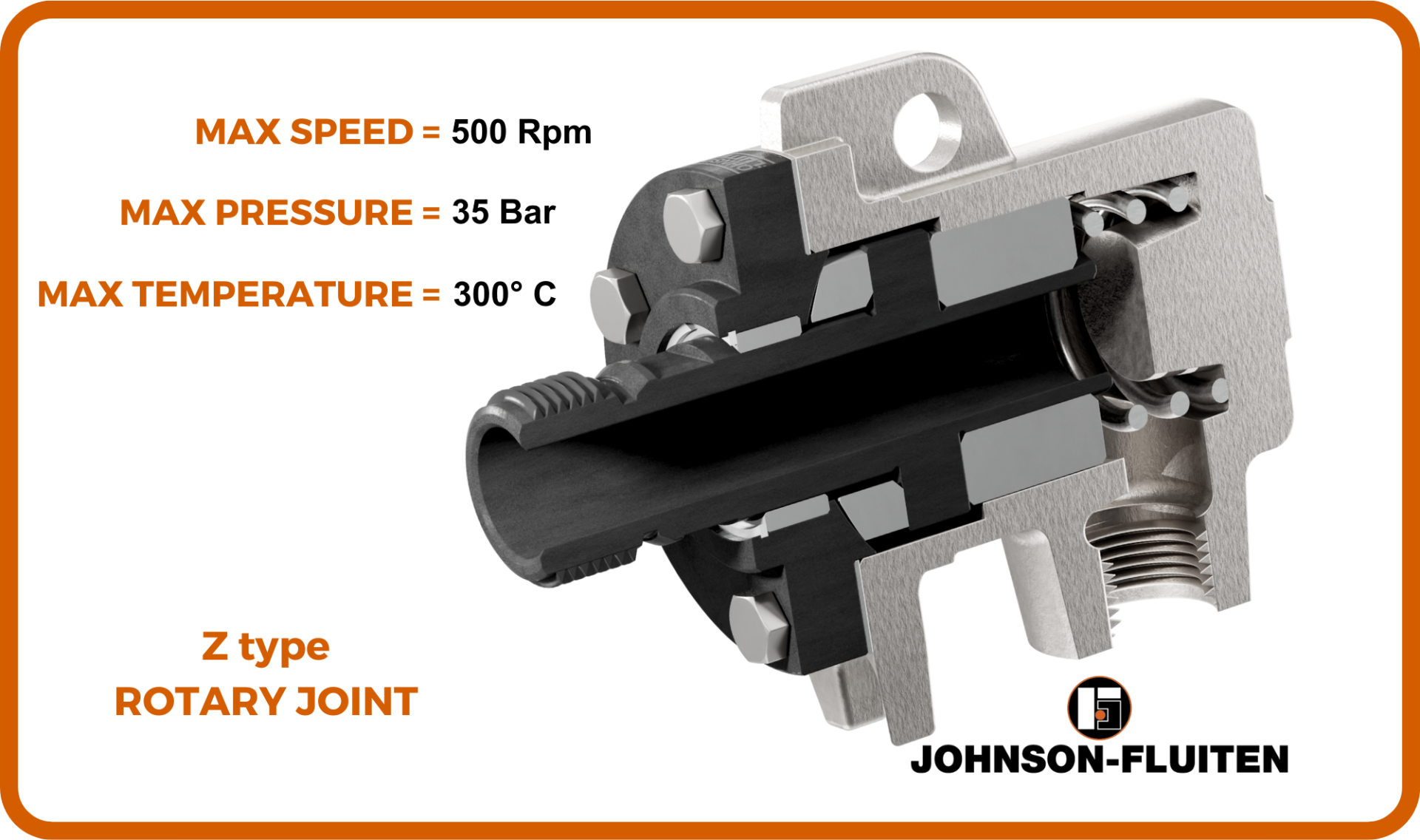

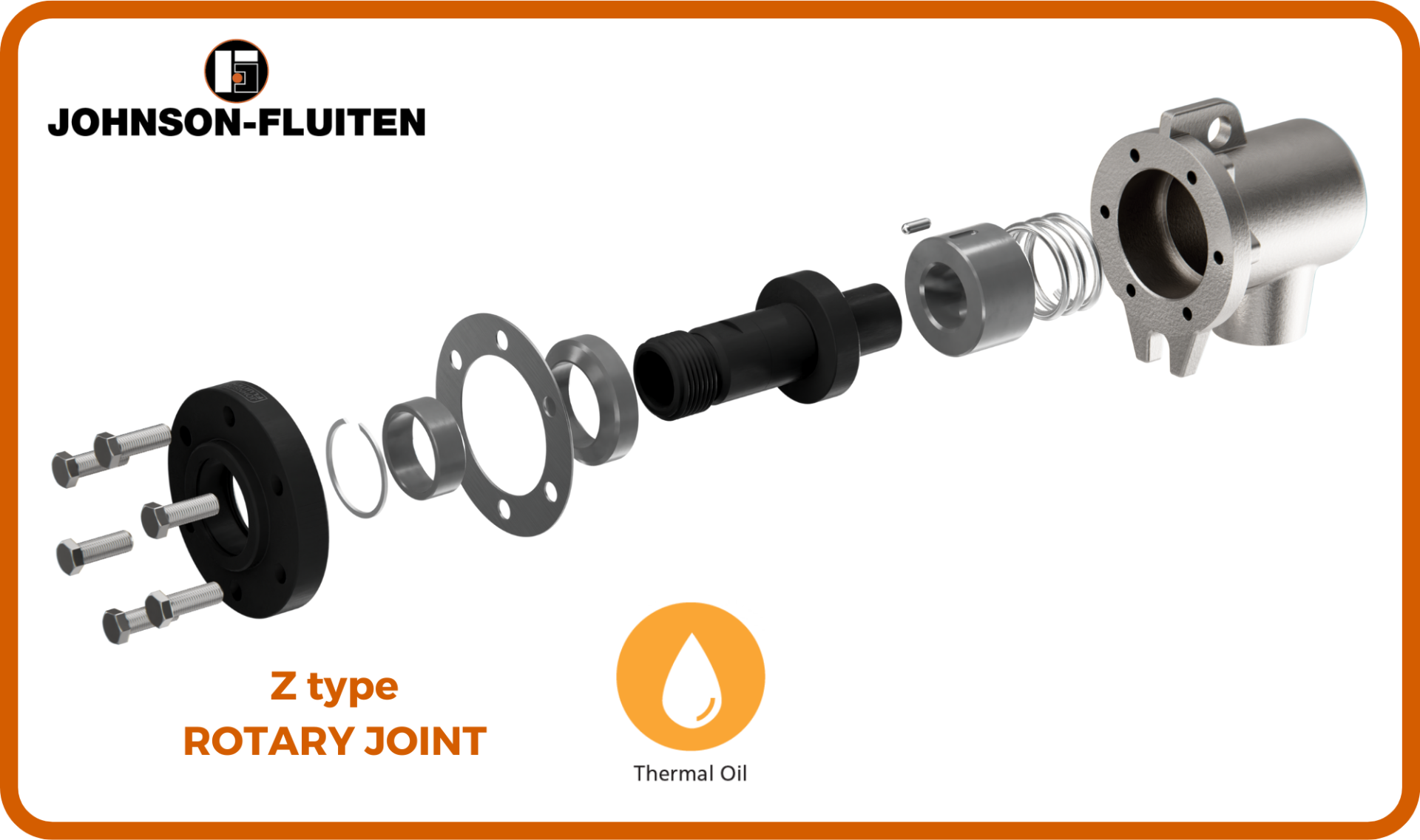

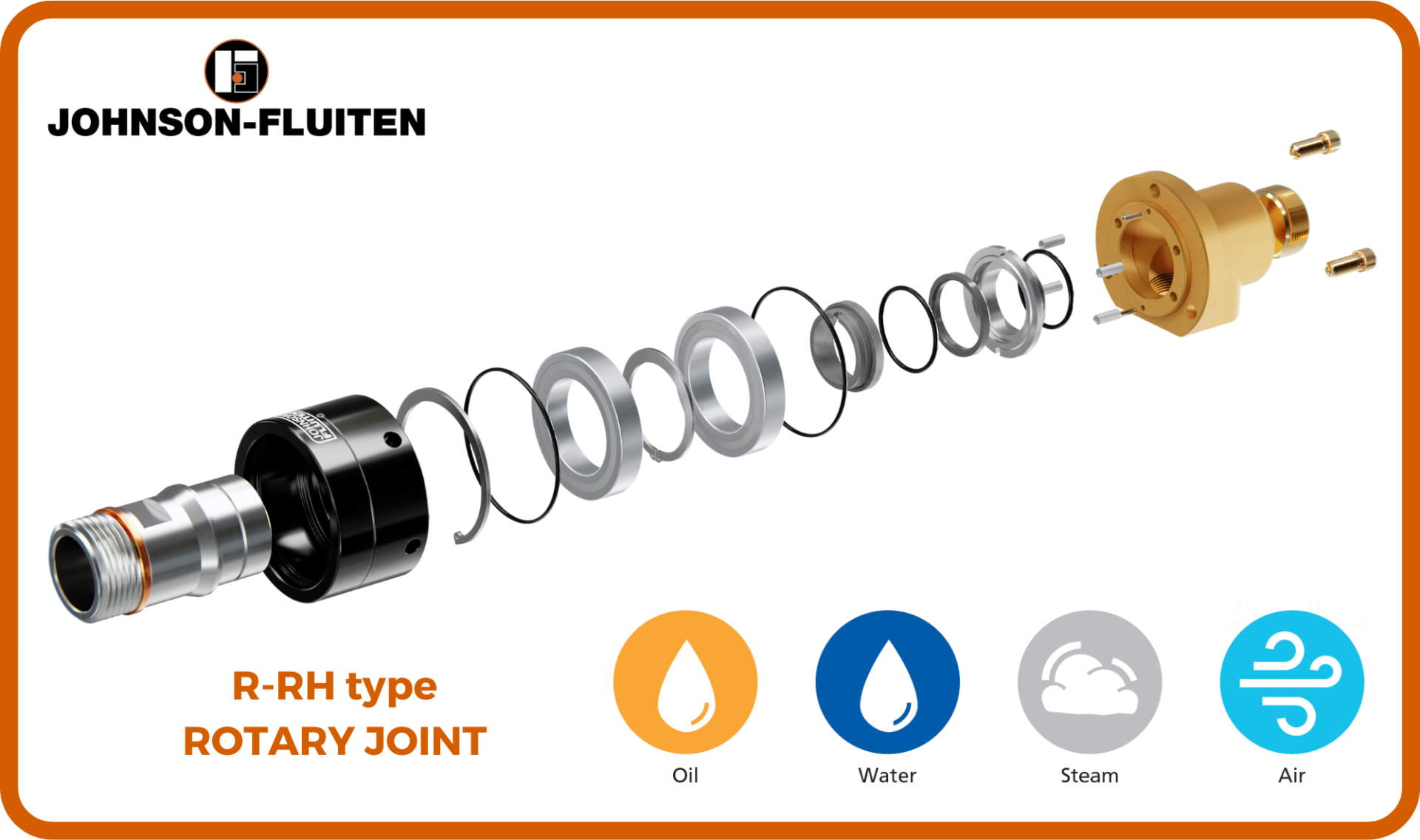

Among the many solutions available in the Johnson-Fluiten range, Matex primarily uses R and RH rotary joints in sizes from 3/8" to 2 ½" and Z rotary joints from 1 ¼" to 2 ½".

The versatility and strength of the R and RH joints make them suitable for many fluids and are mainly used with water, air and oil for heating but also for cylinder cooling. They are also produced in two passages, with fixed or rotating internal siphon, which allows simultaneous fluid inlet and extraction. The maintenance requirements of these rotary joints are minimal; the R and RH joints incorporate Johnson-Fluiten's unique Quick Replacement Design (QRD) technology that allows any work to be carried out with the joint still fitted in the machine, reducing seal replacement procedures to a matter of minutes.

Resistance to temperatures of up to 180°C, pressures of up to 50 Bar and high dynamic applications (up to 3000 rpm) makes them suitable for even the most intense conditions of use. As one of Johnson-Fluiten's most popular couplings, they are always in stock and delivery is very fast.

The Z rotary joints are specially designed to be used with diathermic oil and particularly suitable for high-temperature applications (up to 300°C) due to the graphite inner bushings. Sealing is ensured by an antimony-impregnated graphite ring in contact with the rotor and the cast iron flange with QPQ surface treatment.

Although the Z-joints are so versatile that they are suitable for custom-built machines such as Matex solutions, they are also standard joints and as such are available very quickly.

In addition to product quality, Johnson-Fluiten's experience and history also played a key role in Matex's choice of this supplier.

“Johnson-Fluiten has demonstrated the ability to establish a relationship of trust that is not simply reduced to buying and selling, but to a team effort to find the most appropriate solutions for each individual application”, Marco Calcara continues; “The relationship between customer and supplier, in the case of Matex and Johnson-Fluiten, has turned into a partnership that guarantees success for both”.

Accuracy applications

Matex relies on Johnson-Fluiten products in its cylinder cooling and/or heating systems.

“The performance of these machines depends a lot on the stability of the components in order to guarantee a consistent temperature across the entire length of the machine,” prosegue Calcara; “stability results in a good product and consequently less waste. This becomes a cost saving for the end customer”.

Products made with Matex machines are sold to the major car manufacturers, where the focus on maintaining quality standards is exasperated: any slightest defect is liable to a complaint and consequent non-acceptance of the product. Ensuring a consistently high quality of production is therefore essential.

It was also for this reason that Matex set up an R&D facility with test machinery, able to produce final product samples and simulate industrial processes at a very reasonable cost.

In order to realise this project, Matex needed immediately available components that could guarantee consistent performance and trouble-free service life: due to the wide range of products that have to be produced, the conditions regarding temperature and speed often vary significantly, putting the components under great strain. With Johnson-Fluiten's perfectly calibrated and robustly constructed rotary joints, Matex was able to produce machinery that could withstand changing and strongly varying stresses.

Constant support

Matex greatly appreciated the support provided by Johnson-Fluiten, which emerged as a close partnership, and a way of growing together in trying to find the right solution for each application.

In the automotive market, the rule is 'if a customer doesn't speak up, everything is fine'; the peace of mind and security that Johnson-Fluiten components provide creates added value for both machine manufacturers and end users.

Marco Calcara ends; “Johnson-Fluiten has now become a standard on our equipment; we really see no reason not to continue installing Johnson-Fluiten joints in our future projects, trusting that the quality and reliability will continue”.

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091