Discover how Johnson-Fluiten Rotary improved Kaplan Turbines’ efficiency, productivity and energy saving

Green energy generating a more sustainable world: Discover how Johnson-Fluiten Rotary improved Kaplan Turbines’ efficiency, productivity and energy saving.

Kaplan hydroelectric turbines have been using Johnson-Fluiten rotary unions for years. The precision manufacturing continuous improvement and service have made Johnson-Fluiten an appreciated partner.

The Kaplan turbine, invented 1912, has been a long, proven solution for generating green energy. Kaplan turbines have an efficiency of more than 90%. Controlling the rpm, which is typically between 50-500 rpm, is important to optimize the efficiency.

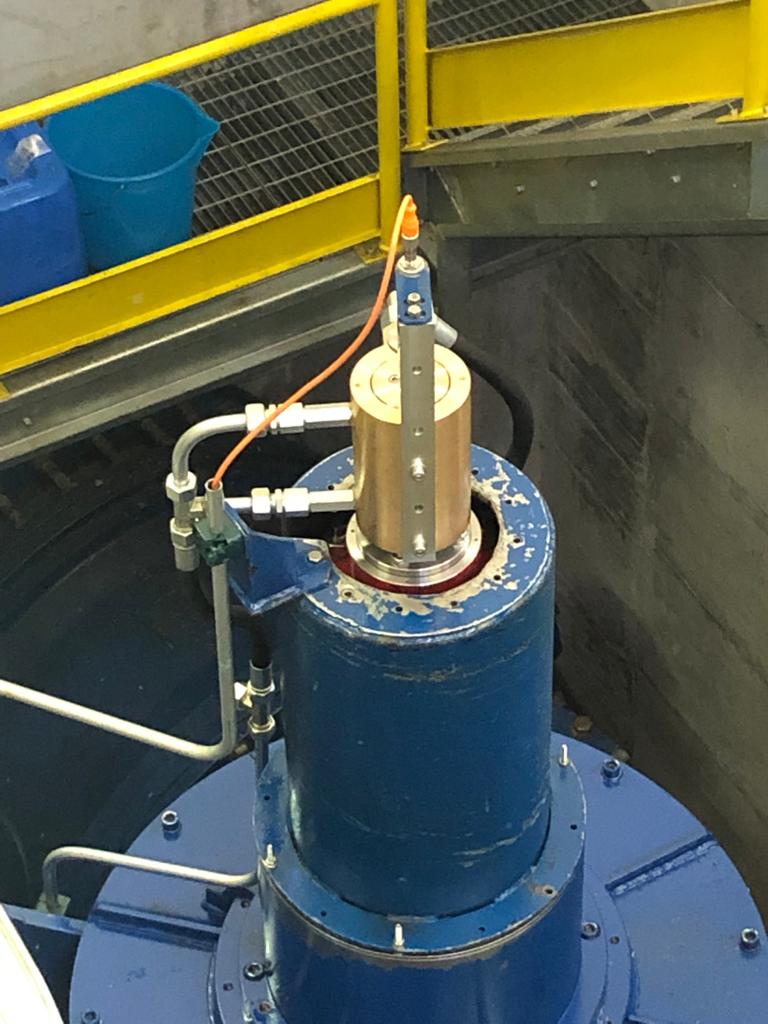

The wicket gate and the blade pitch control the Kaplan turbine’s rpm. The blade pitch on the rotating blades are controlled with 2 hydraulic cylinders. A rotary union transfers the hydraulic pressure from the pump to the rotating blades. The pressure drops over the blade is what creates the rotation.

The hydraulic pressure in the system for the pitch control can be as high as 100 bar (1500 psi). Sealing technology with polymer seals, like lip seals, cannot withstand the pressure in combination with the rpm. The wear on these seals will be too high for the required interval times. Mechanical seals might be able to handle the pressure and rpm, but if a seal would fail it would lead to loss of control of the turbine. A large amount of oil could leak from the system.

Johnson-Fluiten rotary unions are manufactured with a close gap seal. With a small gap manufactured with micron precision, the amount oil leakage passing through the gap can be controlled. Because it is a non-contacting seal, wear is low which results in high reliability and controllability. The leaked oil is captured and put back in the system. This way, waste is avoided as environmental and efficiency impacts on the production process.

Added to it, Johnson-Fluiten can engineer the unions to incorporate mounting positions for sensors or different hose connections and can interchange to older turbines if spare parts are becoming difficult to procure. It increases the productivity and saves time on connectivity issues as procurement needs.

Added to it, Johnson-Fluiten can engineer the unions to incorporate mounting positions for sensors or different hose connections and can interchange to older turbines if spare parts are becoming difficult to procure. It increases the productivity and saves time on connectivity issues as procurement needs.

Johnson-Fluiten is a collaboration of Kadant Johnson and Fluiten Italia Spa. Kadant Johnson has sales and service available on most continents and countries. Fluiten’s design and precision manufacturing of mechanical seals allows Johnson-Fluiten to provide innovative solutions.

In order to profit from Johnson-Fluiten products and solutions and improve your productivity and energy and production efficiency, send us an e-mail: info-jf@johnson-fluiten.com or visit our website at www.johnson-fluiten.com.

We would love to share insights how to improve your business and offer solutions according to your needs.