Rotary Joints 101: What They Are, How They Work, and Why They Are the Heart of Industrial Efficiency

Whether it is paper manufacturing, plastic packaging printing, chemical processing, or operating complex machine tool systems, transferring fluids between stationary and rotating components is a constant engineering challenge.

What exactly is a rotary joint?

A rotary joint, also known as a rotary union, is a precision mechanical sealing device that allows the transfer of a fluid (liquid or gas) from a stationary supply line to a rotating machine component.

Consider a heated roll in a paper mill or a machine tool spindle requiring coolant: the fluid must enter the component while it rotates at high speed, without leakage and while maintaining constant pressure. The rotary joint is the interface that makes this possible.

Common industry terms include:

-

Rotary joints (generic term)

-

Rotary unions (often used for high-speed applications or non-steam fluids)

-

Steam joint

-

Water joint

-

Hydraulic rotary manifold

-

“The Johnson”

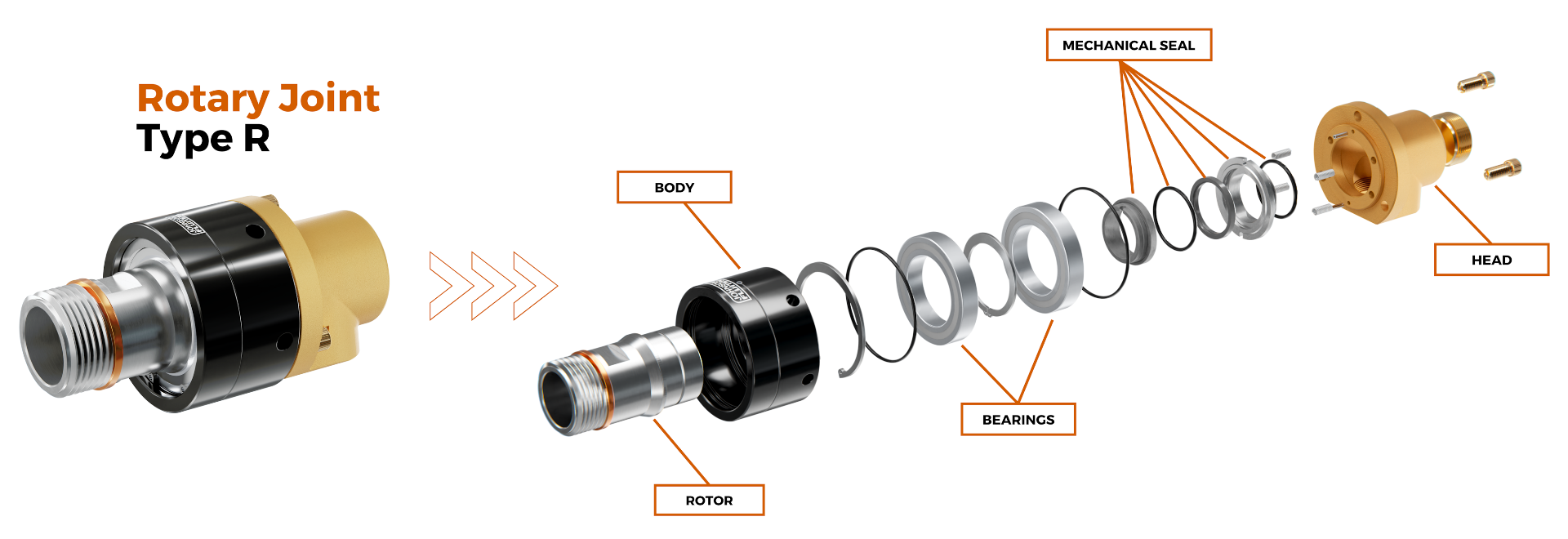

How is a rotary joint constructed?

A rotary joint is not a simple pipe, but an assembly of precisely engineered components:

-

Housing (Body): The stationary part connected to the supply piping. It contains the fluid and provides structural support.

-

Rotor (Shaft/Nipple): The component directly connected to the rotating machinery, with threaded or flanged connections.

-

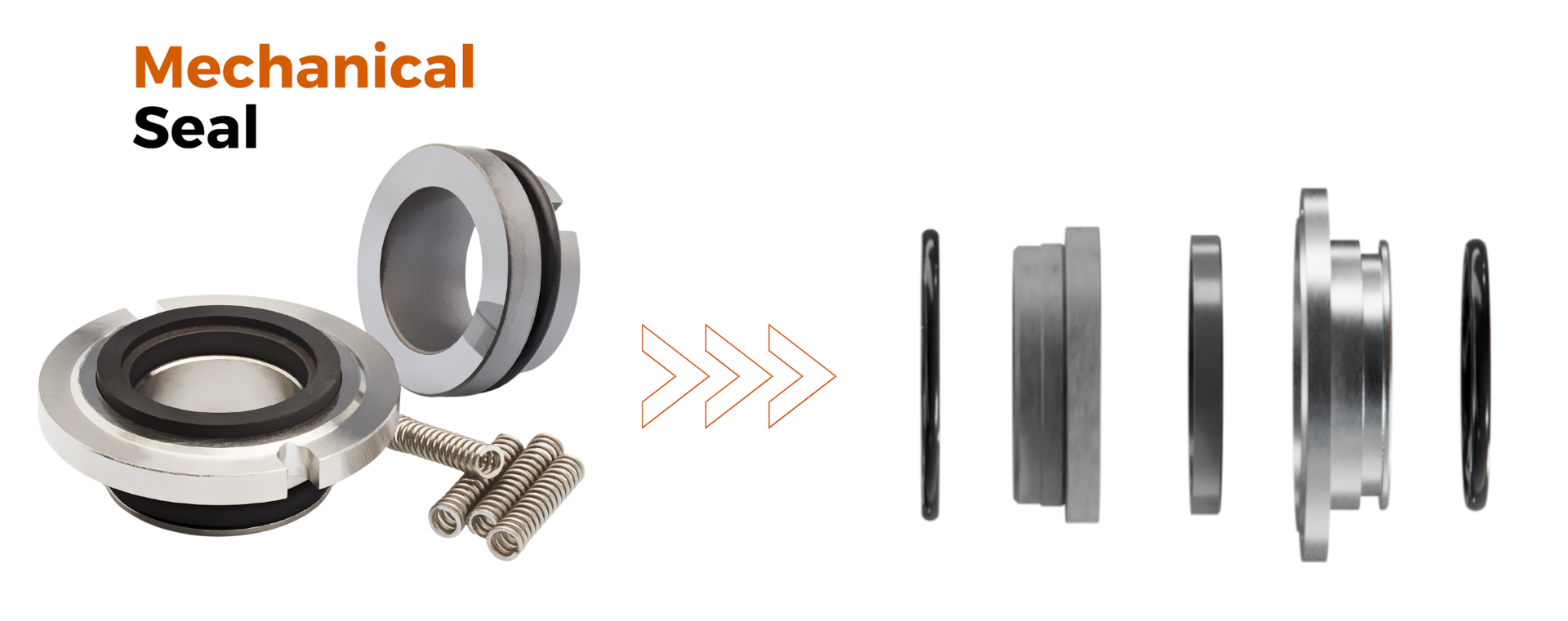

Mechanical Seal: The core of the joint. It prevents fluid from escaping into the environment. Seal quality largely determines service life.

-

Bearings/Guides: Support rotor rotation within the housing, ensuring alignment and reducing friction.

Why is the seal the most critical element?

During operation, the seal is simultaneously exposed to fluid pressure, friction between contact surfaces, and temperature variations. High rotational speeds, aggressive media, or frequent thermal cycles inevitably accelerate wear.

A frequently underestimated factor is that the seal cost represents only a small fraction of the true failure cost. When a seal fails, the issue is not just component replacement, but the impact on process efficiency, energy consumption, safety, and production continuity. In this sense, a rotary joint is only as good as its sealing system.

What is a balanced seal?

Balanced seals are designed to reduce the effect of fluid pressure on the contact force between sealing faces. In these designs, sealing load is mainly determined by calibrated springs, while operating pressure has limited influence.

This results in more stable behavior, reduced wear, and more predictable performance, particularly in water and cooling fluid applications, but also with steam or gases.

Self-supported vs. externally supported rotary joints: how to choose?

In self-supported joints, the housing is mounted directly on the shaft or cylinder, with support integrated into the joint itself. These compact solutions suit many standard applications.

Externally supported joints use brackets or tie rods to support the housing, reducing loads transmitted to the machine shaft. This configuration is often preferred for large diameters, high speeds, or demanding operating conditions.

The correct choice always depends on the application context and plant layout.

Why are rotary joints essential to your production?

It is not just about “transferring a fluid.” A properly engineered rotary joint impacts four key pillars of industrial production:

-

Energy and Thermal Efficiency

In industries such as textile or paper, heat transfer (via steam or thermal oil) must be uniform. Inefficient joints or poor siphoning systems create cold spots on rolls, increasing scrap and energy consumption. -

Reliability and Reduced Downtime

Seals are wear components, but low-quality rotary joints fail prematurely, causing leaks that may damage other machine components or shut down entire lines. The real cost of failure is not the joint price, but factory downtime. -

Workplace Safety

Handling high-pressure fluids, superheated steam, or 300 °C thermal oil involves serious risks. High-quality rotary joints are designed for critical environments, ensuring hazardous fluids remain properly contained. -

OEM Customization

Many applications require tailored solutions. Whether it is a multi-pass rotary joint for robotics (simultaneously carrying air, oil, and electrical signals) or an ultra-high-speed joint for machine tools, customization capability turns a supplier into a strategic partner.

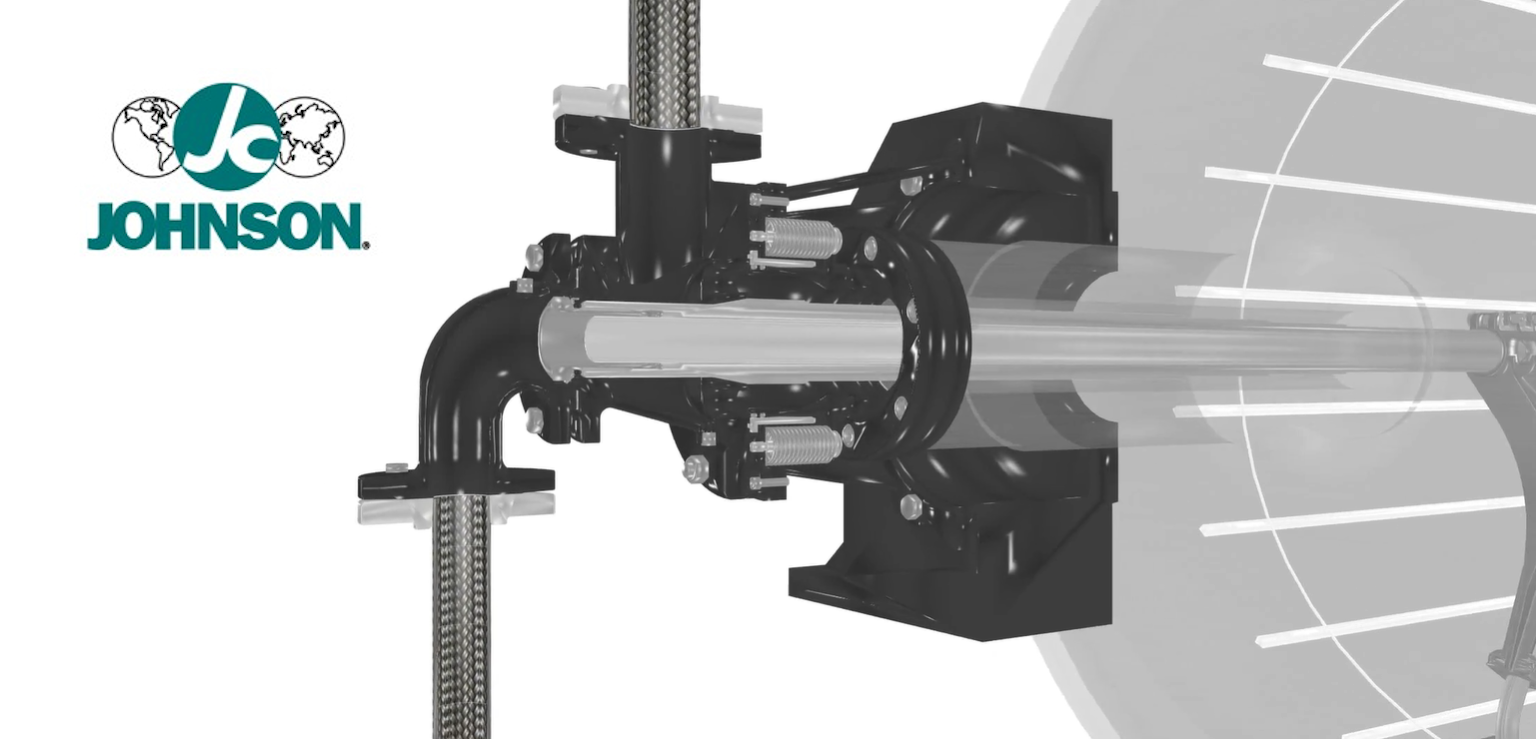

“Pass me the Johnson”: when a brand becomes the component name

In a paper mill, you will rarely hear a technician ask for a “mechanical sealing device for rotating cylinders.” More likely, you will hear: “We need to change the Johnson.”

Since 1933, the innovation introduced by Kadant Johnson has been so disruptive that the company name became the component name itself. For generations of maintenance professionals, “the Johnson” has meant a steam rotary joint—an implicit recognition of reliability that we at Johnson-Fluiten continue to honor by evolving that original technology for Industry 4.0 challenges.

FAQ: Technical questions every Maintenance Manager asks

How do I select the correct rotary joint?

Pipe diameter alone is not sufficient. For accurate selection, our engineers evaluate:

-

Fluid type: steam, water, oil, air, etc.

-

Rotational speed (RPM): critical for bearing and seal technology selection.

-

Pressure and temperature: define housing and seal materials.

-

Required flow rate: to avoid excessive pressure losses.

Why does my rotary joint leak?

Main causes include:

-

Misalignment between joint and machine rotor

-

Piping stresses from rigid pipes instead of flexible metal hoses

-

Poor fluid quality with debris or scale damaging seal faces

- Use of non-OEM spare parts with inadequate tolerances

What is a multi-pass rotary joint?

A rotary union designed to handle multiple fluids simultaneously through separate passages. Essential where a single rotating axis must supply different functions (e.g. hydraulics and pneumatics). Soft seals (O-rings) or special lip seals are used to prevent cross-over between passages.

Essential technical glossary

-

Anti-Rotation Rod: Rigid rods preventing the joint housing from rotating with the rotor.

-

Syphon: Internal piping system (stationary or rotating) allowing condensate or exhaust fluid removal.

-

Q-Flange: Quick-disconnect flange that significantly simplifies maintenance.

-

DuraSeal™: Advanced sealing technology using elastomeric or plastomeric (PTFE) materials for dynamic applications.

-

Sight Flow Indicator: Visual device to monitor fluid flow and detect bubbles or debris.

Ti è piaciuto questo articolo?

- Scopri di più: Visita la sezione prodotti per esplorare le nostra soluzioni

- Contattaci: Hai un problema di tenuta? Richiedi un'analisi tecnica oggi stesso info-jf@johnson-fluiten.com / +39.023394091

Autore dell’articolo