How to maximize the durability and performance of rotary joints? It all starts with proper ALIGNMENT

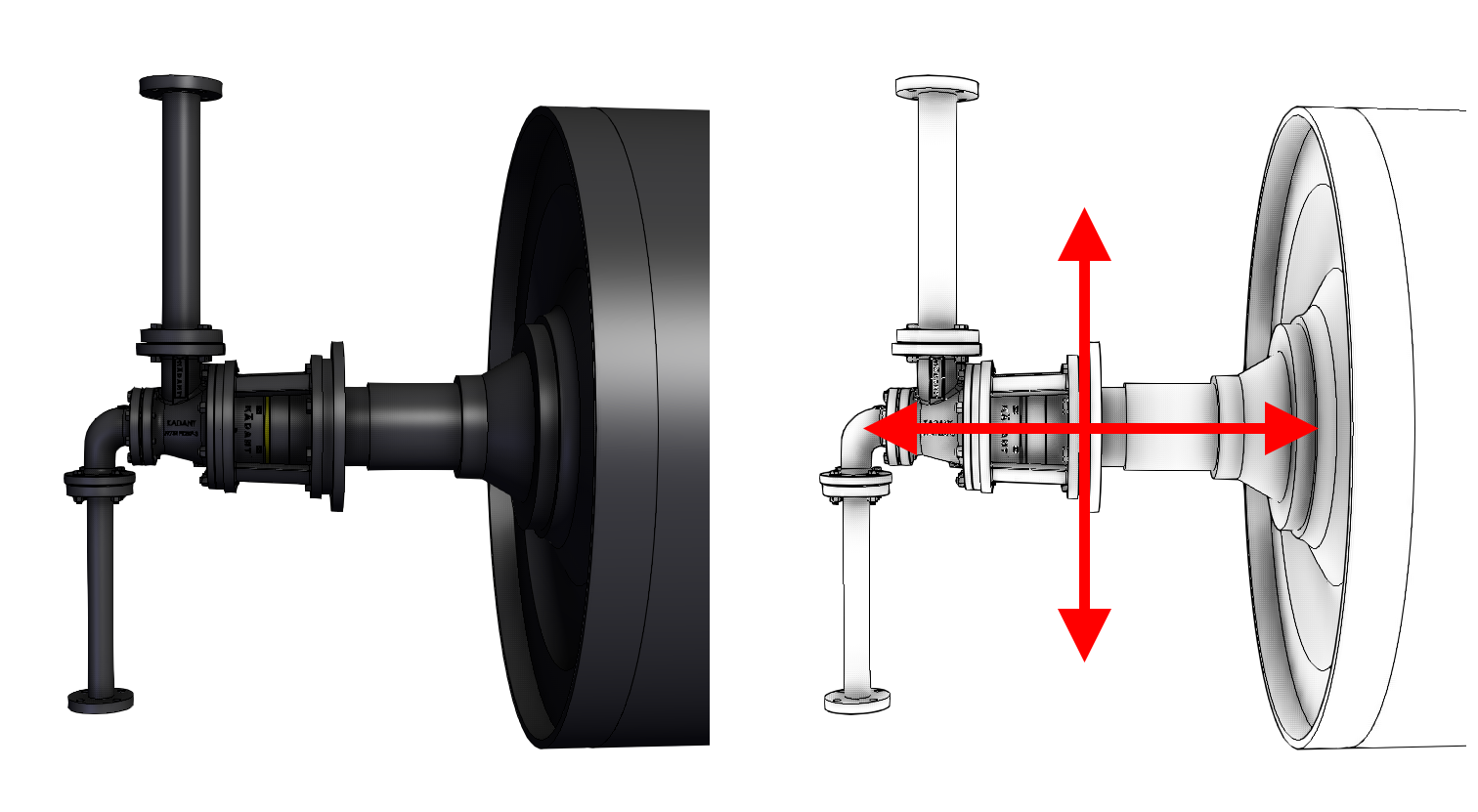

When we talk about performance in rotary joints, alignment plays a crucial role in ensuring optimal service life and performance

While our rotary joints are designed to tolerate some degree of misalignment, taking the necessary steps to achieve better alignment can significantly enhance their longevity. In this article, we will delve into the importance of alignment and provide key insights to help you achieve the longest possible service life for your rotary joints.

What to check to achieve proper alignment

To set the stage for prolonged service life, it is essential to verify the following elements:

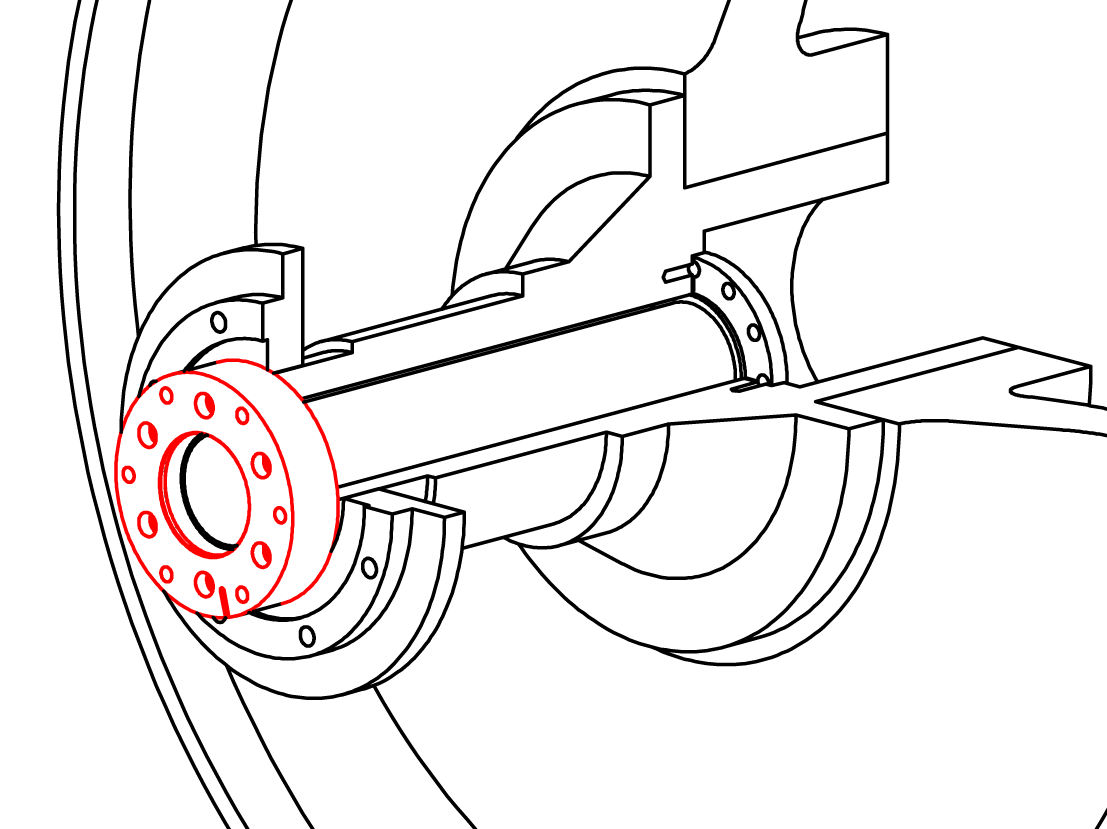

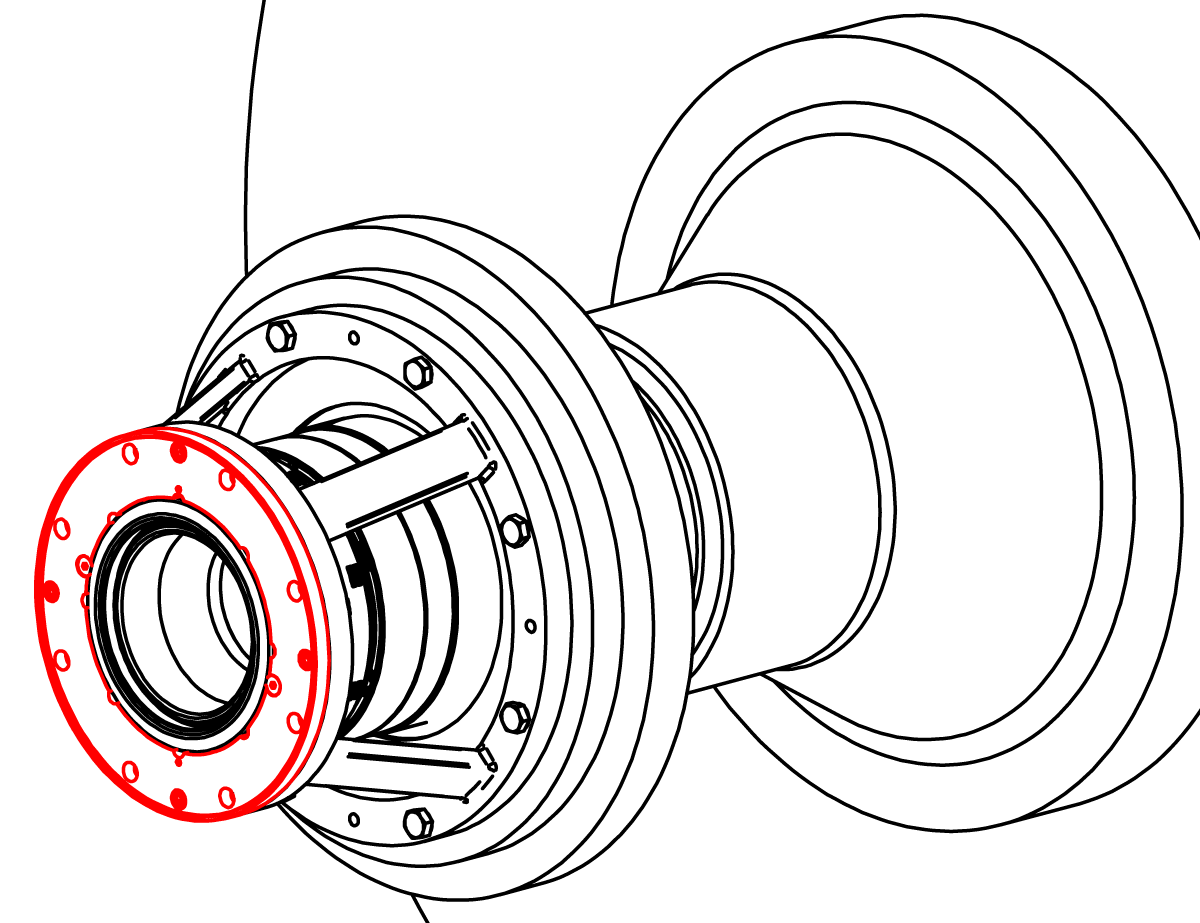

- 1 - Journal Face

The journal face should be clean and square. It is not uncommon for the journal face to sustain damage from previous repairs or steam cutting. Ensuring its cleanliness and squareness will contribute to better alignment.

- 2 - Bolt Tightening

Properly tighten the bolts to the specified torque and in the recommended sequence. This step ensures that the rotary joint remains securely fastened and aligned during operation.

- 3 - Bolt Holes

Verify that the bolt holes are threaded to the correct depth. This attention to detail ensures a secure and stable connection between the rotary joint and the equipment, minimizing misalignment risks.

- 4 - Bearing Housing Mounting Surface

The mounting surface of the bearing housing should be clean and perpendicular to the axis of rotation. Any irregularities or misalignments in this area can impact the overall alignment and performance of the rotary joint.

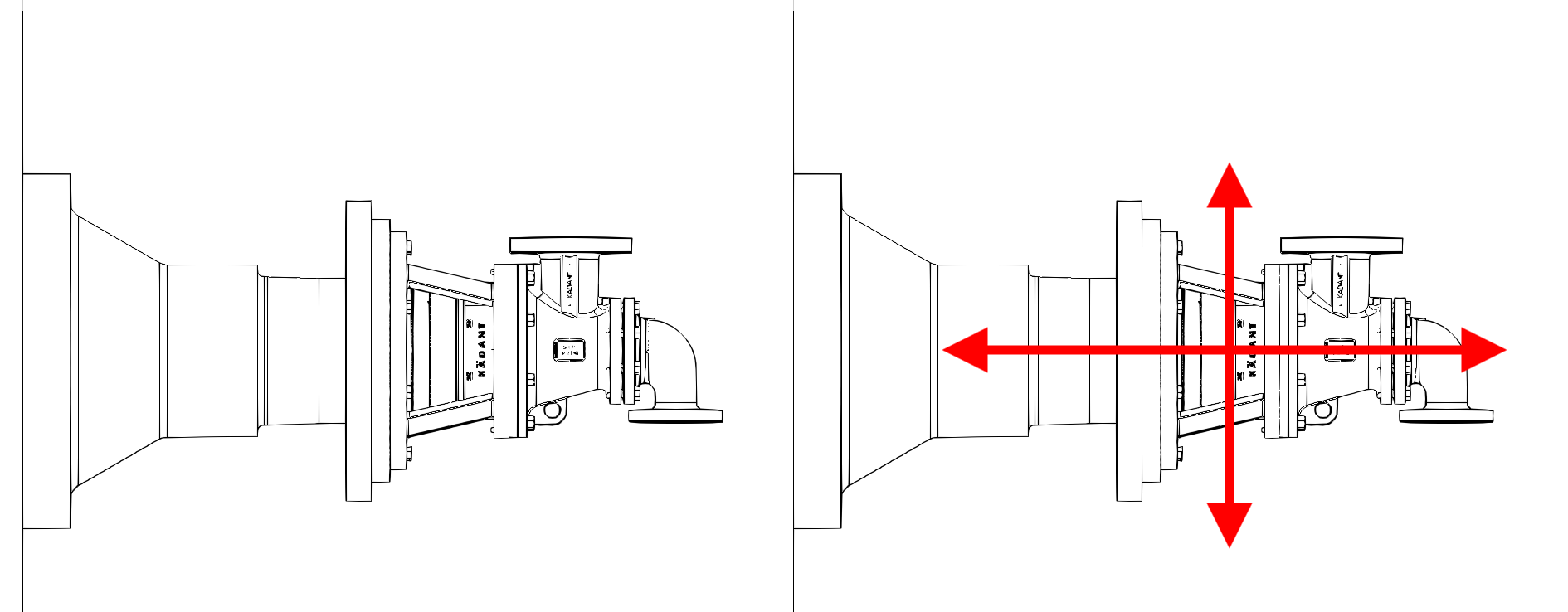

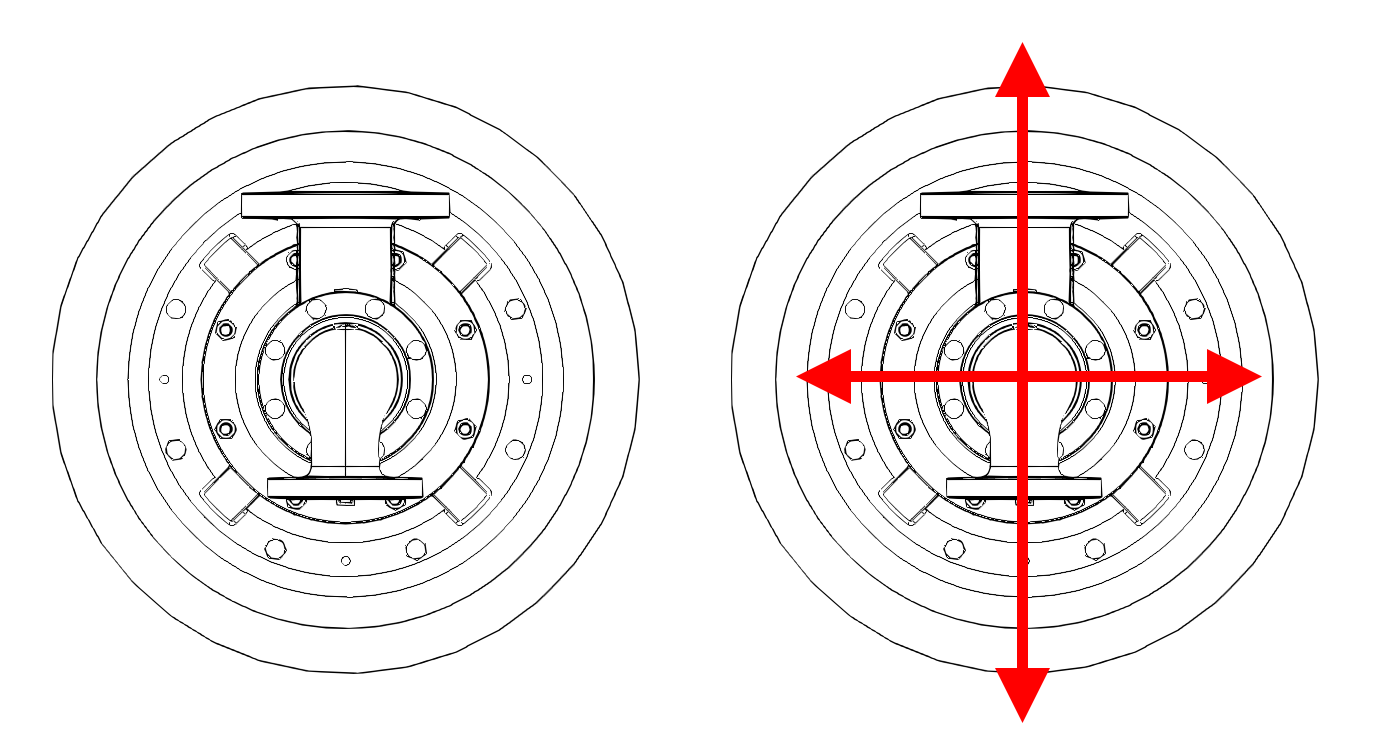

Key alignment variables to monitor

To achieve optimum performance and mitigate any negative effects of misalignment, it is essential to monitor the following variables:

- (1) Check the radial alignment of the wear plate in relation to the axis of rotation. This ensures that the wear plate is properly aligned and engaged, reducing premature wear and extending the service life of the rotary joint

- (2) Monitor the runout on the face of the wear plate with respect to the axis of rotation. Excessive runout can cause uneven wear and affect the rotary joint's performance. Maintaining proper runout minimizes wear and maximizes drying efficiency.

- (3) Verify the radial alignment of the ring bracket pilot bore with respect to the axis of rotation. Proper alignment ensures smooth and reliable operation.

- (4) Check the perpendicularity of the ring bracket joint mounting face with respect to the axis of rotation. Misalignment in this aspect can affect the overall performance and longevity of the rotary joint.

Better alignment = higher reliability

If, in our car, the tires are not perfectly aligned, they can suffer from premature wear. In the same way, rotary joints also suffer when alignment is compromised. By prioritizing proper alignment during installation and maintenance, you can minimize unplanned downtime, increase reliability, and achieve maximum rotary joint drying performance.

Investing time and effort in alignment pays off in the long run, delivering extended service life, improved efficiency, and reduced operational costs. Don't underestimate the power of alignment in ensuring the optimal performance and longevity of your rotary joints.

If you need further advice on rotary joint alignment or are interested in our solutions, please contact our experts

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091