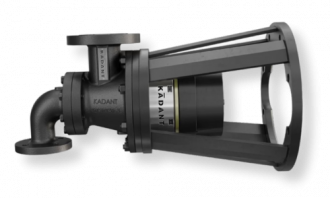

Boost Productivity and Save Energy with PT2X™ rotary joint by Kadant

High-speed paper machines require precise and reliable heat transfer control to ensure uniform drying of the paper product. The PT2X™ rotary joint, exclusively distributed by Johnson-Fluiten for the Italian market, offers a cutting-edge solution to enhance efficiency in the paper production sector.

Discover how PT2X™ revolutionizes production in modern paper mills!

Advantages of the PT2X™ Rotary Joint

-

1- Extreme Reliability: Designed to operate seamlessly even under the extreme conditions of modern paper machines, the PT2X™ ensures continuous performance, reducing downtime.

-

2 - Balanced Seal: This feature evenly distributes pressure, compensating for misalignments, reducing maintenance costs, and improving the system's longevity.

-

3 - High-Quality Materials: Main components are made from polished stainless steel, offering exceptional resistance to corrosion, crucial for demanding production environments like paper mills.

-

4 - Simplified Maintenance: The cartridge design allows quick replacement of wear parts, minimizing downtime. Additionally, a visual wear indicator facilitates maintenance scheduling, preventing unplanned interventions.

Complementary Technologies: Fixed Siphon and Turbulence Bars

The PT2X™ rotary joint works in perfect synergy with Kadant's fixed siphon system and turbulence bars, combining advanced technologies to maximize condensate removal efficiency.

During operation, as the dryer cylinder reaches high speeds, centrifugal force pushes condensate into a liquid ring. Without a proper management system, this ring creates an insulating layer that hampers heat transfer.

Turbulence bars create movement that breaks the liquid ring, ensuring uniform heat transfer across the cylinder’s inner surface. This technology enables faster drying and better energy efficiency.

Benefits for Modern Paper Mills

-

- Improved Operational Efficiency: Effectively removing condensate optimizes steam usage, reducing energy consumption and lowering production costs.

-

- Increased Productivity: Enhanced heat transfer allows machines to operate at higher speeds without compromising the quality of the final product.

-

- Reduced Maintenance Costs: The robust design and intelligent engineering of the PT2X™ and its components decrease maintenance frequency and extend equipment life.

-

- Sustainability: By optimizing energy consumption, this technology not only reduces costs but also contributes to lower CO₂ emissions, enhancing the sustainability of production processes.

Kadant designed the PT2X™ rotary joint as part of an integrated solution, including the fixed siphon and turbulence bars, tailored to the needs of modern paper mills. This technology delivers proven performance, even in the most challenging production environments.

For more information on how the PT2X™ rotary joint can enhance the performance of your paper machines, contact Johnson-Fluiten, the official Kadant partner for the Italian market.

Author of the article

WANT TO KNOW MORE ABOUT OUR PRODUCTS?

DO YOU NEED SUPPORT?

DOES YOUR APPLICATION NEED A SPECIAL SOLUTION?

+39.023394091