News EN

-

Achieving optimal efficiency and enhancing production capacity are cross-industry objectives. Kadant Johnson's turbulator bars stand as a benchmark to modern technological advancements, refocusing the drying process of paper drying. Enhancing Drying Uniformity and Capacity Modern paper mill operations will benefit from our Axial Dryer Bars; they are designed to elevate drying uniformity and increase the capacity of dryer-limited machines. These bars offer a great solution for boosting production or reducing operating steam pressures. Precision Placement for Maximum Impact Strategically placed within the dryer, our bars generate resonant waves in the condensate film, creating turbulence even at high speeds. The result? A remarkable up to 50% increase in heat transfer efficiency compared

-

In the current business context, there are many manufacturers of fluid management components that target the machine builder market. But not many of them can claim to have a track record of success in designing customized solutions for specific applications that are truly capable of providing real and measurable benefits How we achieve, with our rotary joints, a leading place among the most important manufacturers of production lines in the plastics and rubber industry? Let's find out the answer by analyzing the case of the development of the RX rotary joint with a "special head" for a major international customer that manufactures industrial plastic machinery; this project helped to simplify the customer's handling of components and ensured REAL & VERIFIED savings in time, energy and

-

Dec 14 2023

DELFO COLOMBO; FOUNDING THE FUTURE

The 20th anniversary of the company's foundation is an ideal occasion to remember the extraordinary professional and individual personality of Alberto Delfo Colombo, who sadly passed away a few months ago, and who was the real driving force behind the establishment and success of Johnson-Fluiten. The Johnson-Fluiten project comes from the distinctive identities and features of the two companies that shaped it: Fluiten and Kadant Johnson. Fluiten is a historic Italian company representing excellence in the precision mechanical industry. Since 1961 it has produced Mechanical

-

In 20 years of work, Johnson-Fluiten, a leading company in the rotary joint industry, has proven the excellence of its solutions: the wide range of products, capable of satisfying the most demanding requirements in many different applications, is combined with the ability to manufacture rotary joints quickly and tailor-made to specific customer requirements. The company is the result of a joint venture between two well established companies in the sector, Fluiten Italia Spa and Kadant Johnson: in this interview Fulvio Colombo, General Manager of Fluiten Italia Spa, and Mark Strik, Vice President for Europe of Kadant Johnson's Flow Control sector, describe the genesis, growth and prospects of the company twenty years after the foundation of Johnson-Fluiten. A synergic collaboration

-

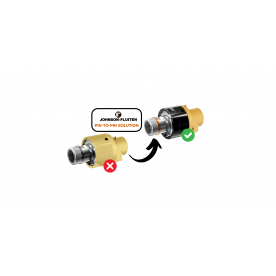

With the cancellation of DP and DX rotary joint lines, you may find it difficult to source the components required to operate your industrial machinery WE HAVE THE SOLUTION FOR YOU Johnson-Fluiten's R-Series rotary joints and Kadant Johnson's RX-Series rotary joints are known for their compatibility with the most widely used rotary joints on the market. You don't have to worry: the R-Series and RX-Series rotary joints are fully compatible with competitors' DP-Series and DX-Series joints, and offer you a pin-to-pin replacement solution*.

-

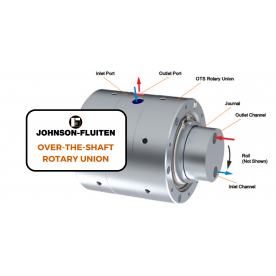

Discover the Modern Applications of OTS Rotary Unions Over-the-shaft (OTS) rotary unions are the backbone of fluid conveyance systems, seamlessly integrating with journals (shafts) that facilitate the flow of liquids into and out of rolls. As the journal rotates, the OTS rotary union seals around it, enabling the smooth transfer of fluids through the channels. These ingenious devices find frequent use in situations where fluid conveyance and the drive system coexist at the same end of a roll. Such applications require the journal to convey fluids while simultaneously transferring torque. Traditionally, you'll find OTS rotary unions in the metal industry, where water cooling is paramount. However, their versatility shines in any scenario where water, steam, or other fluid transfer is essential

-

At MIAC - the International Paper Industry Exhibition - which will be held in Lucca from 11 to 13 October, Johnson-Fluiten teams up with Kadant to present products and solutions that have made the multinational group a benchmark in the industry. Efficiency, Savings and Safety These are the three pillars on which KADANT relies to achieve the core objective of its mission: the improvement of production processes in the paper industry. The target that the KADANT group aims at, with its participation in the MIAC, is not to present itself as a supplier of a wide range of products, but to provide targeted and customised technological solutions capable of achieving tangible and measurable results that bring a real

-

Comerio Ercole is a leading player in the rubber, plastic and non-woven machinery segment. The company is renowned not only for the reliability of its equipment, but also for its ability to innovate. Two testing and research laboratories help to ensure that the company is always at the cutting edge, also thanks to the excellent solutions provided by Johnson-Fluiten Comerio Ercole has a success story lasting more than 130 years: from its beginnings as a craftsman's business in 1885, it has developed into one of the world's leading manufacturers of machines and systems for processing rubber, plastic, woven-non-woven and other sheet materials that require to be compressed, levelled and processed by calendering.

-

We asked Petr Vozábal - an engineer and technical manager of a company that for over 15 years has specialised in machine tool maintenance - who had no doubts; the answer is the rotary joints from Kadant Johnson VOPSS Řepeč s.r.o. began as a company focused on the reconditioning and repair of machine parts for companies engaged in production mainly with machine tools. Today, after many investments and years of success in the Czech Republic market, it has become a true benchmark fo

-

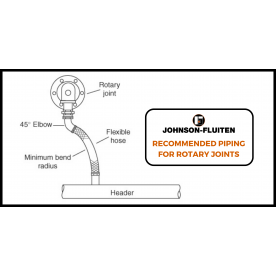

Flexible metal piping is used on the inlet and outlet connections of rotary joints to allow the movement of the joint itself and the thermal expansion of the pipes. The consequences of inadequate piping should not be underestimated. Inadequate installations can cause a number of problems, including: - Excessive force applied to the joint body - Accelerated wear of the guides in self-supported rotary joints - Deflection of support rods in rod-supported rotary joints - Failure of fasteners in nipple flanges and journal flanges To show the relevance of hose installations, consider the following examples: