News ZH

-

At MIAC - the International Paper Industry Exhibition - which will be held in Lucca from 11 to 13 October, Johnson-Fluiten teams up with Kadant to present products and solutions that have made the multinational group a benchmark in the industry. Efficiency, Savings and Safety These are the three pillars on which KADANT relies to achieve the core objective of its mission: the improvement of production processes in the paper industry. The target that the KADANT group aims at, with its participation in the MIAC, is not to present itself as a supplier of a wide range of products, but to provide targeted and customised technological solutions capable of achieving tangible and measurable results that bring a real

-

Comerio Ercole is a leading player in the rubber, plastic and non-woven machinery segment. The company is renowned not only for the reliability of its equipment, but also for its ability to innovate. Two testing and research laboratories help to ensure that the company is always at the cutting edge, also thanks to the excellent solutions provided by Johnson-Fluiten Comerio Ercole has a success story lasting more than 130 years: from its beginnings as a craftsman's business in 1885, it has developed into one of the world's leading manufacturers of machines and systems for processing rubber, plastic, woven-non-woven and other sheet materials that require to be compressed, levelled and processed by calendering.

-

We asked Petr Vozábal - an engineer and technical manager of a company that for over 15 years has specialised in machine tool maintenance - who had no doubts; the answer is the rotary joints from Kadant Johnson VOPSS Řepeč s.r.o. began as a company focused on the reconditioning and repair of machine parts for companies engaged in production mainly with machine tools. Today, after many investments and years of success in the Czech Republic market, it has become a true benchmark fo

-

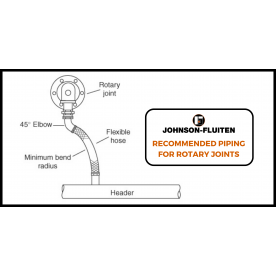

Flexible metal piping is used on the inlet and outlet connections of rotary joints to allow the movement of the joint itself and the thermal expansion of the pipes. The consequences of inadequate piping should not be underestimated. Inadequate installations can cause a number of problems, including: - Excessive force applied to the joint body - Accelerated wear of the guides in self-supported rotary joints - Deflection of support rods in rod-supported rotary joints - Failure of fasteners in nipple flanges and journal flanges To show the relevance of hose installations, consider the following examples:

-

Since 1973, Matex has been designing and manufacturing equipment for textile coating and finishing; in particular, machinery for the production of artificial leather is highly valued in sectors with demanding quality requirements such as the automotive industry. For rotary joints, Matex has no doubt: the benchmark supplier is Johnson-Fluiten Specialised in the creation of tailor-made systems for companies in a wide range of sectors, Matex is best known for its coating lines, capable of creating coated/laminated materials that are highly valued in the furniture, footwear, luxury goods and automotive industries. Matex's coating machines, for example, allow the

-

How do you partner the industry leaders? Competitiveness, speed, service and quality; this is Johnson-Fluiten's recipe for conquering the machine tool market. Let's find out why Porta Solutions chose Johnson-Fluiten as their single-source supplier for rotary joints For 65 years, Porta Solutions has been offering customers real results, even before machine tools. Known and appreciated for its innovative CNC machining centres with three independent spindles, the Brescia-based company specialises in the design and implementation of production systems for mechanical engineering companies. Porta Solutions machining centres guarantee shorter lead times and lower machining costs, an advantage that translates into greater

-

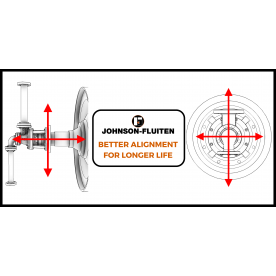

When we talk about performance in rotary joints, alignment plays a crucial role in ensuring optimal service life and performance While our rotary joints are designed to tolerate some degree of misalignment, taking the necessary steps to achieve better alignment can significantly enhance their longevity. In this article, we will delve into the importance of alignment and provide key insights to help you achieve the longest possible service life for your rotary joints. What to check to achieve proper alignment To set the stage for prolonged service life, it is essential to verify the following elements: 1 - Journal Face

-

What are multi-pass rotary joints Multi-passage rotary joints are essential components for systems that require transferring different fluids or needing multiple passages sealed independently during rotation. They are designed to ensure no leakage and that pressure is maintained in each passage. In some industrial applications, it is necessary to transfer 2 or more fluids (e.g. air and hydraulic oil) at the same time, which must not come into direct contact, and these rotary joints are the practical solution to this problem. But how do these products work? How are they manufactured? And what are the factors to consider when choosing the best multi-pass coupling? Let's find out more about these Johnson-Fluiten products made in Italy.

-

WITH 145 YEARS OF EXPERTISE IN THE ENGINEERING AND MANUFACTURING OF INDUSTRIAL SYSTEMS, RODOLFO COMERIO HAS BECOME A LEADER IN THE RUBBER AND PLASTICS EQUIPMENT SECTOR THROUGH TECHNOLOGY AND INNOVATION. THEIR HIGH QUALITY STANDARDS ARE REFLECTED IN THEIR CHOICE OF COMPONENTS: INCLUDING OF COURSE THE ROTARY JOINTS, FOR WHICH THE COMPANY RELIES ON JOHNSON-FLUITEN. Rodolfo Comerio is the main company in Italy in terms of construction of calendering lines and systems for the lamination and embossing of thermoplastic foils and rubber. Founded in 1878, today Rodolfo Comerio

-

A partnership that has lasted for decades: the partnership between Boema, a major manufacturer of equipment for the food industry, and Johnson-Fluiten, a company focused on the design and production of rotary joints, owes its longevity to a shared emphasis on quality, but above all to the ability to meet challenges by finding the best solution thanks to expertise and know-how. For over forty years, Boema has been known by customers all over the world for its systems for the food industry. The constant evolution of the solutions taken to be ahead of processing techniques has allowed Boema to grow and become an international company with more than 220 employees and production facilities occupying a total